Hydraulic Cylinder for Scissor Lift

Hydraulic Cylinders & Parts, Hydraulics System

This type of hydraulic cylinder is appropriate for use in scissor lifts, most often used as the lifting, transferring and moving assistant. In the hydraulic industry, our cylinder is noteworthy for its compact structure, light quality, reliable performance, long service life, easy to disassemble and convenient maintenance.

- Main cylinder model of main platform: 110/63-520

- Auxiliary cylinder model of main platform: 90/50-522

- Main cylinder model of auxiliary platform: 100/60-190

- Auxiliary cylinder model of auxiliary platform: 80/45-192

- Cylinder type: Mater cylinder of double action, auxiliary cylinder of single action

- Rated working pressure: 30 MPa

- Inner diameter of cylinder: 110; 90; 100; 80

- Diameter of piston rod: 63; 50; 60; 45

- Stroke of cylinder: 520; 522; 190; 192

- Oil outlet: NPT3/8 internal thread, NPT1/4 internal thread

- Application: automatic scissor lifts

- Amount: Four cylinders for each lift

- Notes: If you have any questions, please do not hesitate to contact us. Our skilled technicians will give your solutions in as short amounts of time as possible.

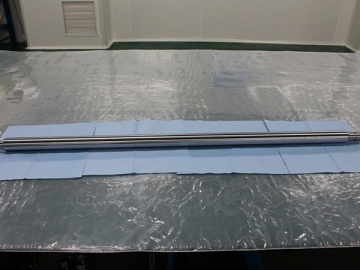

Cylinder Tube

Because each of our tubes must undergo strict examination and inspection, cylinder tube manufactured by Hoyo is well known for its high degree of smoothness and low friction coefficient, providing a good protection of inside sealed parts.

Finished cylinder tube

Finished cylinder tube  Roughness test

Roughness test

Piston Rod

In order for high smoothness and low friction coefficient, we produce piston rods from carbon alloy, process them with cylinder grinder, coated them with hard chromium and finally achieve a roughness degree of 0.2-0.4μm. Under rated working pressure, all piston rods show no fatigue or wear.

Piston rod

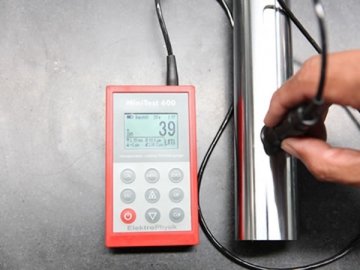

Piston rod  Coating layer test

Coating layer test

Sealing Elements

All of our sealing elements are assembled in our clean room. As for our dust ring, it holds back liquids and other containments in an effective manner. If you are not satisfied with our existing sealing elements, we are also able to provide customized service.

Clean room

Clean room  Piston

Piston

In order to cope with mass production, we bring in many excellent producing machines, such as CNC lathes, ultrasonic cleaning machines, coated lines, welding machines, assembling machines, to name a few.

Roughly processed tubes

Roughly processed tubes  Automatic welding machine

Automatic welding machine  Coated lines for cylinders

Coated lines for cylinders

Our sophisticated and high precision testing devices allow us to produce hydraulic cylinders of superior quality. These testing devices are: integrated test bench, durability test bench, hardness tester, thickness tester, roughness measuring instrument, ultrasonic fault detector, computer controlled pressure test system, etc.

Cylinder test

Cylinder test  Integrated test bench

Integrated test bench  Deflection check instrument

Deflection check instrument