Glass Vial Sterilizing Dryer

The glass vial sterilizing dryer can automatically complete the all procedures, from bottle feeding, preheating, drying and sterilizing, cooling, to discharging. Based on laminar flow principle and hot air high speed sterilization technology, the machine can reach the national cleanliness 3rd level (USA industry standard class 100 cleanliness). This sterilizing drying equipment can be used independently or used in combination with other equipment, like bottle washing machine, filling and sealing machine, etc.

The machine is mainly used for sterilizing and drying of various small glass vials, like 1 to 20 ml ampoules, 5 to 25 ml oral liquid vials and 2 to 20 ml penicillin vials.

- Sterilizing Form: laminar flow heating

- Valid Width: 900 mm

- Sterilizing Temperature: 350 ℃

- Tunnel Cleanliness: Class 100

- Air Exhausting volume: air cooled 5000 m³/h surface cooled 500 m³/h

- Heating Power: 60 kW

- Electric capacity: 70 kW

- Overall Dimension: 4500×2100×2380 mm

- Gross Weight: 3600 kg

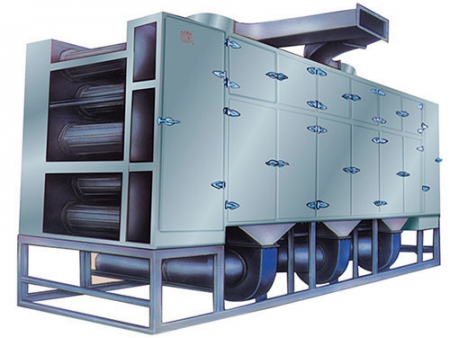

The glass vial sterilizing dryer adopts tunnel structure, consisting of three zones, that is, preheating zone, high temperature sterilization zone and cooling zone. Main parts of the equipment include front laminar flow container, high temperature sterilization part, rear laminar flow container, frame, conveying belt system, air exhaust system and electric control cabinet.

- The glass vial sterilizing dryer ensures bottles are evenly heated, thus eliminating bottle explosion due to uneven heating.

- The wind speed of the preheating zone and the cooling zone is 0.45 m/s±20 %. The wind speed of the high temperature zone is 0.6 m/s±20 %. The air pressure difference between the cooling zone and the outlet is +10 to +15 pa, so the working pressure inside the tunnel is maintained to be higher than pressure outside the tunnel. This ensures class100 laminar flow effect of the tunnel.

- The equipment adopts chain drive and uses the conveyor belt with sideboard. This avoids bottle falling and breakage caused by bottom belt or side belt offtrack and crawling. So the cross contamination caused by the moving of the side belt is avoided.

- The high temperature hot fan adopts water circulation cooling system. The heat of the bearing is taken away by water circulation, which prevents bearing damage due to high temperature.

- The sterilizing drying machine adopts advanced PLC, human-machine interface to monitor the operating status. Trouble causes and simple solutions are displayed on the interface. The control system can cooperate with systems of washing equipment, filling and sealing equipment to realize linkage control.

- The machine adopts stainless electric tube for heating, which ensures fast temperature rise and even heating. The temperature can be adjusted within 350 degrees.

- When the tunnel temperature is lower than 100 degrees, the control system will automatically cut off power supply. When the temperature of the tunnel is over 100 degrees, the fans can't be turned off, so as to protect the HEPA filter. Each fan is controlled by one transducer.

- The system is equipped with protection devices. If the dryer doesn't reach the set temperature, the washing machine and the conveyor belt will stop. If any the fan fails, the dryer will stop heating.

- Surface air cooler is used. The air circulation of the cooling zone is inner circulation, so there is no need to collect a large amount of air from clean room and exhaust moisture air, thus reducing the amount of fresh air supplied to the clean room by air supply system. This can lower the purification cost.

- According to customer's requirement, we can equip the conveyor belt with CIP device. This can ensure the cleanness of the belt, and thus, the quality of the products conveyed.

- The adoption of new technique contributes to longer life of the filter due to the even distribution of the air pressure.

- The control system of the glass vial sterilizing dryer provides two control modes, including day mode and night mode. The day mode is started during daytime operation, and the equipment operates in normal mode. When there is no production at night, the night mode is started, and the electricity heating tube won't work. However, the laminar flow fans at two ends keep working, so as to guarantee the class 100 laminar effect.

We are a professional glass vial sterilizing dryer manufacturer in China. We also provide plastic infusion bottle welding machine, bottle capping machine, carton elevator, and much more.