KJ 210 Hydraulic Top Hammer Drilling Jumbo

Functions and features

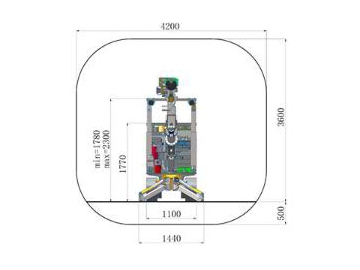

KJ210-type full-hydraulic tunnel jumbo is applicable for hard-rock mine tunneling operation in the small section tunnel with section scale of 15m2 (width 4.2m× height 3.6m). And it can meet any angles and positions required by the construction on this section.

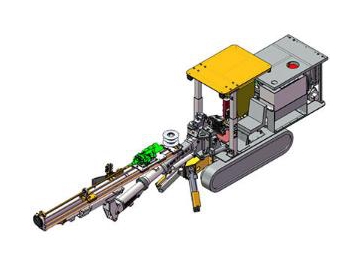

The drill carriage is equipped with support frame. In case of operation of drill carriage, the front support leg is used for winch, so as to ensure steady and reliable operation.

The hydraulic system of drill carriage is equipped with perfect protection device: After rock drilling, the jack drill will be stopped automatically; anti-clamping protection device and fault alarm protection device for low oil level, over-high oil temperature and filter clogging.

The control buttons and operating valves are installed by centralized way, which is convenient for operation;

The drill boom of jack drill goes up and down steadily and rotates flexibly. The drill hole is positioned accurately;

The finished automobile is arranged properly and each maintenance part is well-protected and is easy to maintain at the same time.

High-frequency impact jack drill optimizes the transmission efficiency of impact wave, enhances the drilling rate, reduces consumption of drilling tools and enhances the serviceability rate of equipment by adopting stair piston;

A series of automatic function is conductive to the driver concentrating on drilling safely, quickly and accurately.

Reliable universal arm is equipped with the best section covering shape, and the propulsion beam can turn over by 360°, so as to be convenient for quickly achieving drilling and positioning.

It is optional to increase diesel engine power station so as to be convenient for transport of drill carriage; the diesel engine power station adopts modular design, which is convenient for assembly and disassembly;

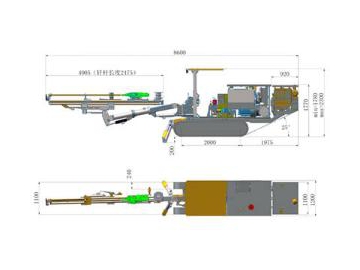

Boundary dimension (including optical auxiliary power station)

| Boundary dimension and weight | Drilling system | ||

| Length | 8600mm | Rock drill | HC50/R38 |

| Width | 1200mm | Impact power | 13kW |

| Height | 1780mm | Surge pressure | 130bar |

| Weight | 6200kg | The maximum rotary pressure | 150bar |

| Running speed (Horizontal) | 2km/h | Frequency | 62Hz |

| Maximum grade ability | 200 | Torque | 325Nm |

| Safety protection | Hole diameter | Φ38-76㎜ | |

| Noise level | <100dB(A) | Turnover of propulsion beam | 360° |

| Adjustable security ceiling | Meet anti-rolling and anti-rock fall requirement | Compensative travel of propulsion beam | 1200㎜ |

| Wind and water circuit system | Drill depth | 2100㎜ | |

| Air compressor | 1×JN5 | Model of drill boom | K10 |

| Displacement | 0.5m3/min | ||

| Pressure | 8bar | Electric hydraulic power pack | |

| Shank lubrication device | Electromagnetic lubricant pump | Electric motor | Three-phase motor |

| Gas consumption for lubrication | 0.3 m3/min | Impact/ propulsion/drill boom | Axial variable displacement piston pump |

| Oil consumption for lubrication | 180-250g/h | Rotation | Gear pump |

| Water pump | 1×CR3 | Filter fineness | 10μ |

| Power | 1.5kW | Hydraulic oil tank | 240L |

| Pump output | 3m3/h | Hydraulic cooler | Water cooler |

| Base plate | Operating voltage | 380V | |

| Base plate model | Caterpillar base plate | Frequency | 50Hz |

| Drive system | Driving motor reducer | Startup method | Star delta |

| Working condition and winch mode | Front support leg for winching | Specification of the recommended cable | 3×35 1×16 |

| Auxiliary winch | Hydraulic lift winch | ||

| Optional diesel engine of power station | YC2108 | ||