CV Lines for 6-35kV Rubber Cable Production

Baicheng offers horizontal continuous vulcanization (CV) lines that are designed for continual extrusion of products with rubber insulation, especially to produce rubber cables of voltage up to 35kV.

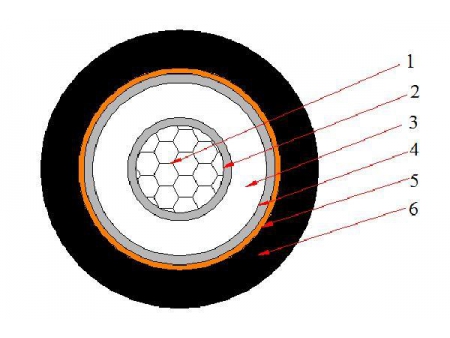

This line is equipped with 3 extruders and one common crosshead, capable of extruding three layers of conductor screen layer, insulation layer and insulation screen layer in one single operation. The finished MV cables support a voltage rage between 6Kv and 35kV, which are ideal for use in power distribution and transmission lines.

- Triple extrusion process for rubber cables of voltages up to 35kV;

- Capable of manufacturing power cables used for a variety of applications either in low voltage or medium voltage;

- Triple crosshead provides great convenience and ease of alignment;

- Water circulating cooling;

- Telescopic tube is made of stainless steel 304;

| Voltage class | Rubber: 6-35kV | ||

| Conductor size | Cu core: 25-630mm2 Al core: 50-800mm2 | ||

| Max. cable weight | 9kg/m | ||

| Max. cable diameter | 60mm | ||

| Cable construction | Conductor screen (inner semiconductor layer) 0.5-1.5mm | Insulation 1.2-10.5mm | Insulation screen (outer semiconductor layer) 0.5-1.5mm |

| Line speed | 0-40m/min | ||

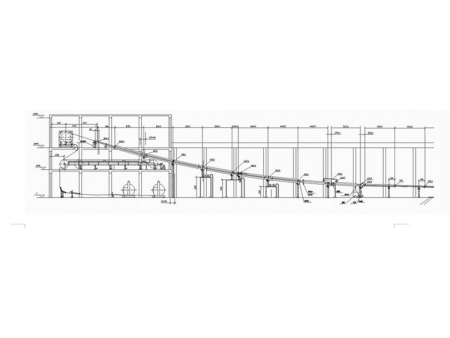

| Line execution | Half catenary | ||

| Length of cross-linking section | Approx. 41m/6 sections (6 tubes) | ||

| Length of cooling section | 36m/6 sections (6 tubes) | ||

| Arrangement of extruders | Φ65 extruder for conductor screen Φ120 extruder for rubber Φ90 extruder for insulation screen | ||

| Electricity | Installation capacity 500kVA | 380 V ±10% 50Hz±1% | 3 phase 4 wire |

| Water | Water pressure 0.2-0.6MPa | Water consumption 15m3/h (circulating water from reservoir) | |

| Compressed air | 0.6-0.8MPa | Air consumption 0.8m3/min | |

| Over saturated steam | Pressure 1.8MPa | Consumption 240kg/h | |

| Saturated steam boiler (prepared by user) | Pressure 2.5MPa | ||

Extruder & Crosshead

Triple extrusion lines have three extruders connected to one common three-layer crosshead for the simultaneous extrusion of conductor screen layer (inner semiconductor layer), rubber insulation layer and insulation screen layer (outer semiconductor layer).Control System

The control system makes sure the entire VCV line run synchronously. All the electrical drive systems can work simultaneously, or to be controlled independently by single machine. Emergency stop is possible for individual units such as pay-offs, accumulators, extruders and take-ups respectively.