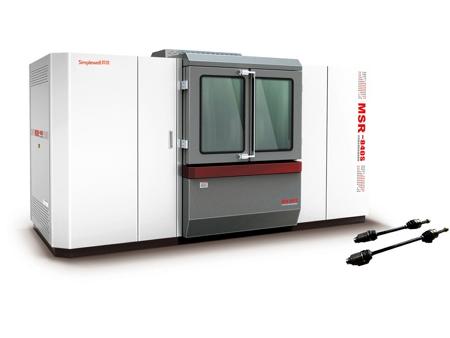

Car Intercooler Thermal Shock Test Chamber

Request a Quote

Application of Intercooler Test Chamber

The testing chamber is mainly used in the intercooler thermal shock tests to see the durability of intercooler as well as test the impacts of alternating temperature on the welding performance and intercooler tubes.

Compliant with QC/T 828-2010 standard, the intercooler test chamber is a good choice for pressure pulse tests and radiator cyclic tests.

Technical Parameters of Intercooler Test Chamber| Low temperature range | 10°C to 80°C |

| High temperature range | 80℃ to 300℃ |

| Insulation time | 0 to 5min |

| Temperature control precision | ±3℃ |

| Temperature change speed | 2 to 15℃/s, adjustable |

| Test pressure | 0 to 300kPa (Precision: ±10kpa), adjustable |

| Cycle frequency | ≥30 times/h |

| test airflow | 300 to 3000kg/h (Precision: ±10kg/h), adjustable |

| Heat-up time | ≤30min |

| Number of sample | 3 |

| Test environment temperature | Normal temperature |

| Sample size (mm) | (L)1500× (W)1500× (H)500 |

| Max. weight of intercooler (kg) | 50 |

| Max. cooling area (m²) | 40 |

Related products

Send Message