Concrete Curing Autoclave

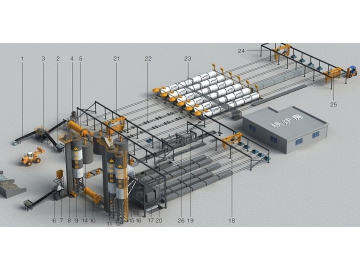

Application

The cut concrete blocks must be placed into the concrete curing autoclave for autoclaving in order to ensure the AAC blocks achieve a certain hardness.

Concrete curing autoclaves are used for autoclave curing of concrete blocks, and thus allowing the concrete block to complete hydrothermal synthesis and obtain different mechanical properties. The working pressure of the concrete curing autoclave is 1.3MPa~1.6MPa, and the working temperature of concrete curing autoclave is 191℃~201 ℃.

Autoclaving Time

The concrete blocks need to go through several stages for complete autoclaving. This includes:

- Before Autoclaving: 30min

- Vacuum Pumping: 30min

- Temperature Rise and Pressure Rise: 90min

- Constant Temperature and Constant Pressure: 480min

- Temperature Reduction and Pressure Reduction: 90min

- After Autoclaving: 30min

Parts

With a durable structure and reliable safety, the concrete curing autoclave is composed of the autoclave body, autoclave lid, orbit, pressure gauge and safety valve.