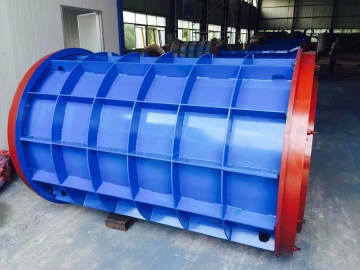

Concrete Pipe Form (Roller Type)

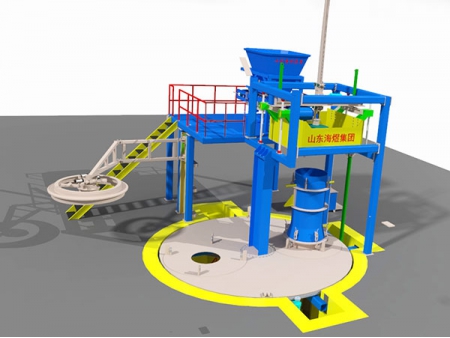

Concrete Pipe Mold, Sewage Pipe Production, Concrete Mold Solution

This roller type concrete pipe form is well suited for the manufacture of concrete water pipes that are 2 meters long and have an inner diameter of 200-2000 mm. Equipped with advanced technology, the concrete pipe form has a smooth inner wall. According to the connection ways, the pipe form can be divided into rigid joint and pin joint type. Classified by pipe end, the pipe moulds are available in plain-end, tongue-and-groove and bell-and-spigot type. With different bearing capacity, the pipe forms have I, II and III degree.

-

Plain end concrete pipe

-

Tongue-and-groove pipes

-

Bell-and-spigot pipes

Attractive Advantages of Concrete Pipe Form

1. Made using high quality steel, the concrete pipe form is composed of two semicircular columns, two circular sealing rings and one separating ring. The separating ring is most often used to divide the 2010mm long mold into two sections to produce short pipes.

2. With an anti-leakage design, the pipe molds produce water pipes with smooth ends and at a fast speed.

3. Friction rings inside the mold are all made from quality cast steel.

4. Purchased from reliable steel manufacturer, the steel plates have good abrasion resistance.

5. Carbon-dioxide arc welding and plasma cutting techniques are applied to get nice welding and precise cutting, which in turn increases the mold durability and prolongs its service life.