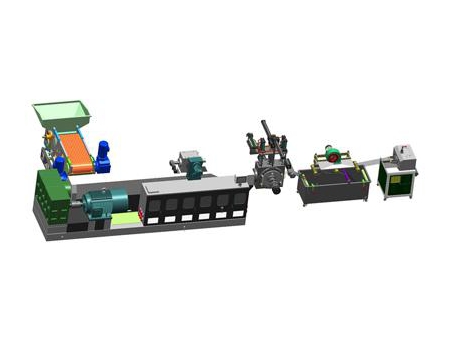

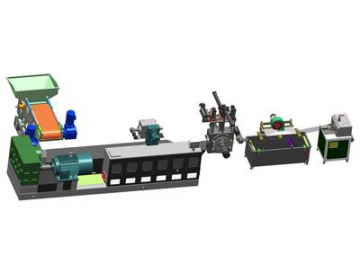

Plastic Recycling Line, Pelletizing Extrusion Line

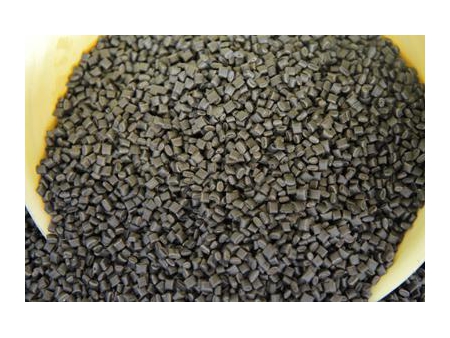

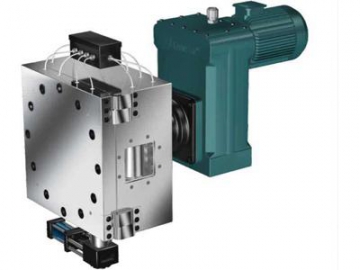

The granule extruder is used for plastic recycling and granulation, and is capable of handling PP, PE, PVC and any other plastics, as well as films with water, woven bags, and jumbo bags. We also offer customized filtration equipment according to customer needs, and a full production line consists of a feeding device, granulator, filter, cooling device, and control system. The granule extruder line will be debugged before delivery, and our technicians will provide onsite installation, debugging and training for customers.

Why LEENY developed this granulation line?A traditional granule extruder only produces one plastic type, and for manufactures that need to produce different plastics, they need to buy several machines. To avoid this, our research team developed an all-purpose forced feeding granule extruder that will satisfy the granulation requirements of any plastics, and will greatly reduce the production cost. All-purpose means it is suitable for all plastics, and forced feeding indications the tank chain feeding device, through which high pressure will dehydrate the raw materials when entering the feeding inlet.

Working processExtrusion softening, extrusion plasticizing, coarse filtration, extrusion and fine filtration, cooling, granulation.

Parameters| Items | Screw Dia.(mm) | L/D | Screw speed(rpm) | Power of main Motor(kw) | Output(kg/h) |

| HGL120 | 120 | 25-34 | 60-120 | 55-110 | 300-500 |

| HGL140 | 140 | 25-34 | 60-120 | 75-132 | 500-800 |

| HGL160 | 160 | 24-32 | 60-120 | 110-160 | 600-1000 |

| HGL180 | 180 | 25-35 | 60-120 | 160-220 | 800-1400 |

| HGL200 | 200 | 30-35 | 60-120 | 220-300 | 1000-1700 |

- The tank chain rotating device drives forced feeding and creates a fully-enclosed structure, which functions as two-sided extrusion and automatic dehydration.

- During extrusion, the heating unit in the compression zone completely softens and shrinks the plastic, which reduces the abrasion loss of the screw and improves the production efficiency.

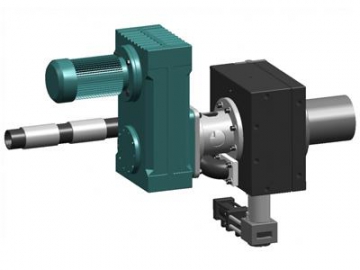

- Side feeding inlet in the bottom of the screw offers no feeding resistance. Two sides of the feeding inlet can both be opened, and the screw can be directly repaired in the event of damage.

- The screw on this granulator is designed for a high-speed and high-output performance, with very little extrusion resistance, and the output is double that of a conventional screw.

- After a long work period, the impurities congestion in the screw will reduce output, which is why our granule extruder will automatically remove contaminants from the screw, or change the barrel inner sleeve in order to remove any impurities, thus solving screw congestion.

- One screw can match two or three machines (venting outlets), which requires less space and saves costs.

- Two filtration procedures (coarse and fine filtration), the mesh size up to 100, PLC controlling continuous production, fully automatic operation available.