CNC Gantry Machining Center, Double Column Machining Center

This gantry milling machine’s spindle axis is perpendicular to the workbench. It is a heavy duty lathe specially designed for machining large components, and is primarily used in heavy duty industries, such as aerospace, automobile production and ship building industries where there is a significant need for machining large and complicated workpieces, such as airplane beams and frames, and large machinery components. The gantry milling machine is a large lathe intended to process large, complex components across a variety of industries.

Gantry milling machines produced by Tying CNC

- X-axis travel :1300mm

Y-axis travel:1100mm

Z-axis travel:520mm

Positioning accuracy:0.035/1000mm

Maximum weight on table:2500kg -

- X-axis travel :1600mm

Y-axis travel:1100mm

Z-axis travel:520mm

Positioning accuracy:0.035/1000mm

Maximum weight on table:2500kg

-

- X-axis travel :2000mm

Y-axis travel:1400mm

Z-axis travel:800mm

Positioning accuracy:0.035/1000mm

Maximum weight on table:3000kg

-

- X-axis travel :3200mm

Y-axis travel:1400mm

Z-axis travel:800mm

Positioning accuracy:0.035/1000mm

Maximum weight on table:5000kg

-

- X-axis travel :3300mm

Y-axis travel:1850mm

Z-axis travel:800mm

Positioning accuracy:0.035/1000mm

Maximum weight on table:8000kg

-

- X-axis travel :3000mm

Y-axis travel:2400mm

Z-axis travel:1000mm

Positioning accuracy:0.035/1000mm

Maximum weight on table:8000kg

-

- X-axis travel :3000mm

Y-axis travel:2700mm

Z-axis travel:1000mm

Positioning accuracy:0.035/1000mm

Maximum weight on table:8000kg

-

- X-axis travel :4000mm

Y-axis travel:2700mm

Z-axis travel:1000mm

Positioning accuracy:0.035/1000mm

Maximum weight on table:10000kg

-

- X-axis travel :4200mm

Y-axis travel:2800mm

Z-axis travel:1000mm

Positioning accuracy:0.035/1000mm

Maximum weight on table:14000kg

-

- X-axis travel :5000mm

Y-axis travel:3100mm

Z-axis travel:1000mm

Positioning accuracy:0.035/1000mm

Maximum weight on table:18000kg

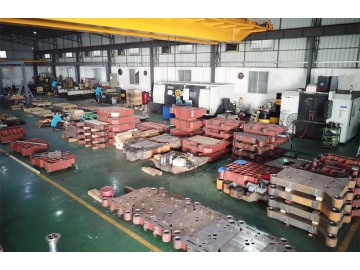

Samples machined by gantry milling machine

- The entire machine is comprised of the gantry and base, which ensures the machine stability during machining, and improves machining precision.

- A complete set of additional machining heads allows for a flexible machining capacity.

The control system can be changed depending on client requirements, such as a tool storage that can be assembled to hold more tools. Please click on each for more detailed information.