CNC Woodwork Machines

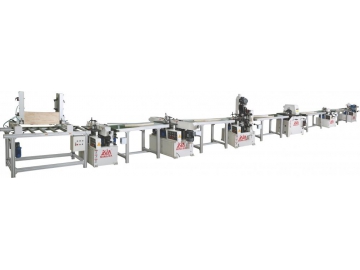

Mingda provides a variety of CNC woodworking machinery widely used for furniture, construction, decorative, and art ware industries. Our CNC machinery completes all working processes according to numeric codes and does so with a high accuracy and production of the most high-quality woodwork without extra material waste. Our CNC woodworking machinery is the best choice for a variety of production facility sizes.

Our CNC woodworking machinery completes a variety of woodworking processes, including sawing, cutting, cutting different curved profiles, drilling, reaming, slot milling, and shaping.

- The CNC band saw is used to precisely saw different wood furniture or cut wooden chair joint boards. It processes wood precisely and accurately with the use of an advanced CNC system to automatically design the cutting layout using DXF file processed via CAD. After processing, the margin between two workpieces is as small as 3mm, thus saving both time and material.

- The CNC 5 axis copying lathe is suitable for different wood furniture processes, including lathe, shaping, milling, and sanding. This equipment uses an advanced CNC system to carry out instructions according to CAD drawing tools, ensuring it is easy to learn and safe to operate. Compared to traditional processing methods, a CNC copying lathe saves time and money, and it is equipped with high quality components, including a Siemens spindle motor, and a HIWIN linear guideway.

- The CNC end tenoner is used to process different tenon in wooden furniture such as tables, chairs beds, and doors. Mingda’s CNC tenoner features an easy man to machine interface operation. After setting the workpiece shape via the touch screen and inputting the tenon and wooden board size in the dialog box, the process begins. It is easy and efficient.

- The CNC dovetail machine is suitable for producing different dovetail tenons and is capable of processing both flat and curved boards, making it applicable for use in wooden furniture with a dovetail tenon structure.

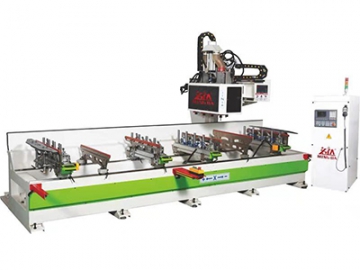

- This CNC machining center features a gantry mode movement, servo driving system and Taiwanese Syntec control system to ensure a fast, accurate processing. It is widely used for wood and other drilling, reaming, milling slot, and contour machining applications with nonmetal materials. It also significantly improves the processing efficiency and yield.

- Our CNC slot milling machine is an affordable, high speed and accurate machine suitable for threading, grooving and drilling of a variety of wood furniture, and is designed with 4 different positions to ensure a continuous, efficient timber machining. The CNC slot milling machine also utilizes an advanced, numerical control system, making it consistently accurate and easy to operate.

We also customize CNC woodworking machinery to meet customer requirements. Founded in 2002 and backed by extensive experience, we use core techniques and components sourced by internationally known manufacturers, including Schneider electrical components, Rexroth transducers, HIWIN linear rails, Siemens electric motors, Delta servo motors, and ordinary components made using highly precise CNC machinery to manufacture highly reliable, and cost effective CNC woodworking machinery. Please do not hesitate to for a free initial consultation.