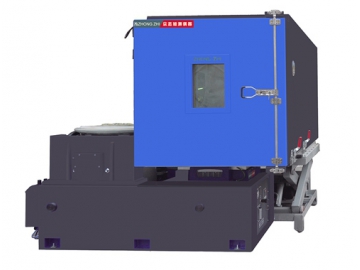

Thermal Shock Chamber (Three Zones)

Request a Quote

The thermal shock environmental chamber is designed with three independently controlled zones: hot zone, cold zone and test zone. The tested product will be put into the test zone and the hot and cold air will be transferred to the test zone to simulate rapid changes in temperature.

Both the interior and exterior of the thermal shock chamber are made of SUS 304 stainless steel. The exterior features baking finish. The insulation materials are aluminum silicate fiber cotton or PU Styrofoam which both provide high density and high temperature resistant performance.

Our thermal shock chambers can be customized with special dimensions and functions to meet your individual needs.

Parameters

| Model | CZ-I-42(A~C) | CZ-I-80(A~C) | CZ-I-150(A~C) | CZ-I-252(A~C) | CZ-I-450(A~C) |

| Workspace Dimensions WxHxD(cm) | 40×35×30 | 50×40×40 | 60×50×50 | 70×60×60 | 80×75×75 |

| Exterior Dimensions WxHxD(cm) | 140x180x145 | 148X190X155 | 160x200X175 | 175x210X187 | 190x220x200 |

| Temperature Range | 150℃~A: -45℃; B: -55℃; C: -65℃ | ||||

| Temperature Range in Hot Chamber | 60℃~ 150℃ | ||||

| Temperature Range in Cold Chamber | -10℃~-65℃ | ||||

| Temperature Changing Speed in Hot Chamber | RT~200℃ About 35min | ||||

| Temperature Changing Speed in Cold Chamber | RT~-70℃ About 85min | ||||

| Changeover Time Between Hot/Cold Chamber | ≤5min / ≤5sec | ||||

| Temperature Homogeneity | ±0.5℃ / ±2.5℃ | ||||

| Power | AC380V 50HZ/60HZ 3∮ (Optional) | ||||

| Approximate Weight | 700Kg | 900Kg | 1200Kg | 1400Kg | 1900Kg |

Features

- The thermal shock chamber uses touch operation which is very convenient to use.

- It features wide setting range for high temperature shock or low temperature impact. The maximum time is up to 999H. The maximum cycle is up to 9999 times.

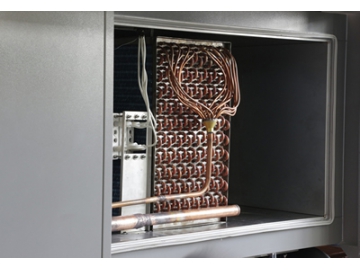

- It uses binary refrigeration systems which feature rapid cooling rates. The cooling method is water-cooled.

Related products

Send Message

Most Recent

More

Other Products

Three Zone Thermal Shock Test Chamber, Item KTS-966B Hot and Cold Temperature Test Chamber

climate-tester.com

Three Zone Thermal Shock Test Chamber, Item KTS-966B Hot and Cold Temperature Test Chamber

climate-tester.com

Three Zone Thermal Shock Chamber, Item KTS-100D Cold and Hot Temperature Testing Chamber

climate-tester.com

Three Zone Thermal Shock Chamber, Item KTS-100D Cold and Hot Temperature Testing Chamber

climate-tester.com

Videos