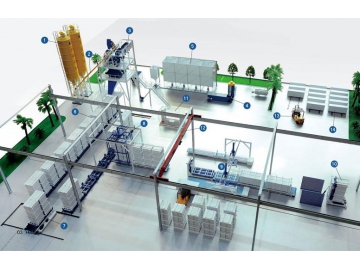

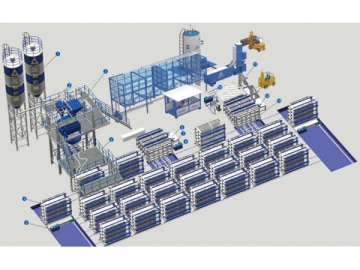

Wall Panel Production Line, Vertical Type

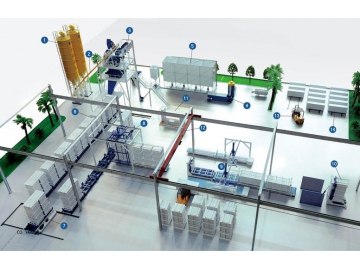

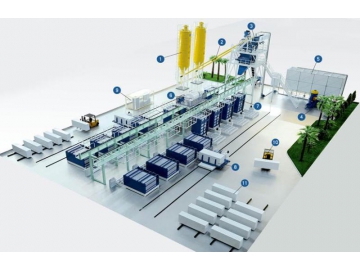

Sanlian's vertical type wall panel production line mainly consists of concrete mixing system, slurry injection system, wall panel molding machine, turning device for mould filling, transport system, turning device for demoulding, automatic stacker and separator, etc. Each equipment in the concrete product plant is engineered from high quality steels including Q235, Q345, 40Cr and 45# steels, aluminum alloys, etc., some of which have been processed by hardening and tempering, carburizing and oxidizing treatments, thus ensuring higher equipment longevity.

Automatic Lightweight Wall Panel Production Line - Vertical Type

1. Silo

2. Screw conveyer

3. Mixing system

4. Slurry infusing platform

5. Transfer cart

6. Wall panel molding machine

7. Turning device for mould mounting

8. Pre-loading device

9. Hydraulic station

10. Automatic stacker

11. Stack separating unit

12. Turning device for demoulding

13. Separator for demoulding

Working Principle

1. Materials are mixed in the mixing tank for a specific period of time after accurate dosing. Mixed materials are put into a storage hopper and then infused into the aluminum moulds in the wall panel molding system.

2. Filled wall panel forming moulds are transported by a transfer cart to the curing section and after curing, they will be transported to the demoulding section by another transfer cart.

3. A turning device turns the molding machine over 90° and opens the moulds. Then, automatic stacker and separator draws wall panels out of the moulds and stack them separately.

3. Finally, forklift transports the stacked wall panels to storage yard for further curing.

Main Features of the Wall Panel Production Line

1. Automatic slurry infusing process improves wall panel molding speed and keeps the product quality in the minimal error. In general, error is controlled within ±2%.

2. Due to the use of automatic turning device and automatic demoulding device as well as wall panels stacking and separating unit, whole wall panel manufacturing process features higher speed and efficiency.

3. Depending on centralized control by PLC, the building machinery realizes automatic running, automatic start and stop and precise positioning, thus improving production efficiency.

4. Wall panel machine in the system is proud to make 2-3 times more wall panels than traditional horizontal machine. This drastically improves equipment utilization efficiency.

| Type | JQ1000 with Lift Port | JQ1000 |

| Charging Volume(L) | 1600 | 1600 |

| Discharging Volume(L) | 1000 | 1000 |

| Max. Grain Size of Aggregate(mm) | 5 | 5 |

| Speed of Mixing Blade(r/min) | 26.4 | 21.9 |

| Mixing Blade(PCS) | 6 | 6 |

| Model of Mixing Motor | XWD8-59-15kw | |

| Power of Mixing Motor(KW) | 15 | 15 |

| Model of Winch | 500.3 | ---- |

| Power of Winch(KW) | 4.5kw/i=20.27 | ---- |

| Height of Unloading Material(mm) | 1850 | 1850 |

| Model of Water Pump Motor | 3 phase self-priming pump | |

| Power of Water Pump Motor | 1.1KW | 1.1KW |

| Frame Dimension in Working | 3900×4728×4382 | 3900×1550×5750 |

| Frame Dimension | 7560x6060x6565 | 7560x3065x6565 |

| Net Weight(T) | 6.2 | 5.5 |

| Function | Transferring the material and inject material into wall panel molding machine under high pressure |

| Infusing Volume | 1m3 |

| Working Pressure | 0.4Mpa |

| Motor Power | Traveling motor: 1.1KW Air compressor motor: 3KW |

| Frame Dimension | 2755x1200x1665mm |

| Component | Slurry container, rail, air compressor, pipe |

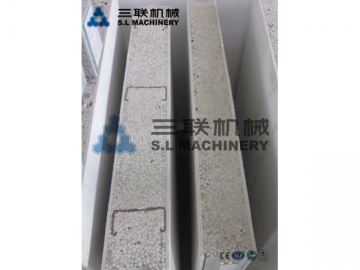

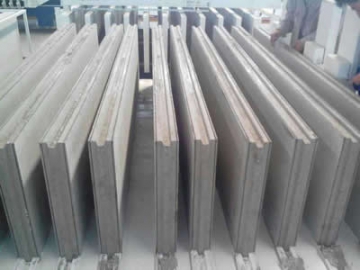

| Feeding Capacity | 5m3 | |

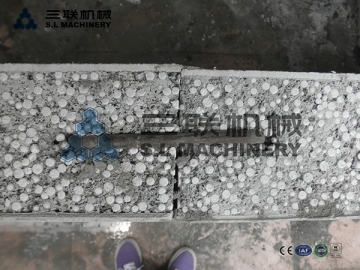

| Finished Wall Panel Dimension | 2440x600x75 | |

| 2440x600x90 | ||

| 2440x600x100 | ||

| 2440x600x120 | ||

| 2440x600x150 | ||

| Molding Time | Two Hours (High aluminium cement) | |

| Mould Clearance | 2mm | |

| Numbers of Pallet Provided Per Time | 75mm | 46PCS |

| 90mm | 40PCS | |

| 100mm | 36PCS | |

| 120mm | 30PCS | |

| 150mm | 26PCS | |

| Installed Capacity | ≈ 65kw | |

| Maximum Pressure of System | ≈ 16Mpa (vertical type overturn cart) | |

| Function | (Pulling panel out off wall panel molding machine, collecting wall panel together, turning over wall panel with 90°, and taking wall panels to the outside with forklift) | |

| Motor Power | Hydraulic unit motor | 6.6kw |

| Traveling motor | 1.5kw | |

| Demoulding motor | 1.1kw | |

| Cylinder Travel | Wall panel pushing cylinder | 1200mm |

| Turnover cylinder | 650mm | |

| Weight | 2.2T | |

| Component | Hydraulic unit motor, Turnover machine, Demoulding device, Wall panel pushing device, Rail, Traveling motor, Electrical control cabinet | |

| Frame | 4350×3612×1150mm | |

We welcome you to contact us to get further detailed information!