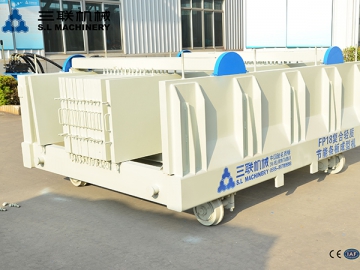

Wall Panel Production Line, Mobile Type

Designed for making large size solid and hollow wall panels, our mobile type wall panel production line is composed of a variety of systems including concrete mixing plant, automatic slurry infusing system, hydraulic mobile wall panel molding machine, trolley system, positioning system, automatic demoulding machine, automatic stacker, combined transfer cart, etc.

Relying on transfer cart and trolley system, the concrete molding machines transfer repeatedly among the curing area, slurry infusing area and demoulding area to complete production processes.

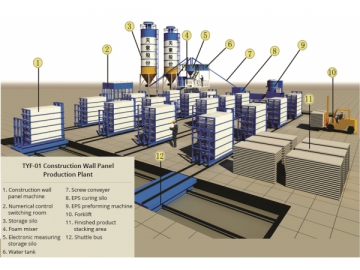

Automatic Lightweight Wall Panel Production Line - Mobile Type

1. EPS Pre-expander

2. Boiler

3. Fluidized Bed

4. EPS Curing Silo

5. Screw Conveyer

6. Powder Silo

7. Mixing System

8. Steep Making Machine

9. Slurry Infusing Pump

10. Mobile Hydraulic Molding Machine

11. Trolley System

12. Automatic Stacker

13. Control Room

14. Forklift

15. Storage Yard

16. Transfer Cart

17. Hydraulic Station

Equipment Construction

Materials: Q235, Q345, 40Cr and 45# steels, aluminum alloys, etc.

Treatments: Hardening and tempering, carburizing and oxidizing treatments are conducted on some of the materials to improve equipment's lifespan.

Features

1. The mobile type wall panel production line is excellent for the investment where annual production is less than 100,000m2.

2. The whole concrete product plant ensures small floor space while high productivity.

3. It is specially configured to make solid and hollow wall panels with 50-200mm thickness and 2270-3000mm length.

4. The building material production line features centralized waste collection, keeping workshop clean and ensuring low cost of investment.

Working Principle

1. After precise batching and mixing, materials are infused into the wall panel molding chamber that is constructed from aluminum molds. Molding units move while other equipment keeps stationary.

2. The molding machine will open the molds after water panels are molded. The stacker with demolding function will draw them out of the molds and stack them with 90° turnover.

3. Finally, forklift transports the stacked wall panels to storage yard for curing.

Description of Hydraulic Wall Panel Molding Machine

-- First, put the aluminum alloy mould between two molding boards;

-- Second, put the fiber cement board inside the mould;

-- Third, make the aluminum and mould board into a close chamber;

-- Last, and make a hole on the side aluminum mould for slurry infusing.

Characteristics of Hydraulic Wall Panel Molding Machine

Lightweight;

Sound insulation;

Heat insulation;

Warm preservation;

Water proof

| Type | ||

| Charging Volume (L) | 1600 | 1600 |

| Discharging Volume (L) | 1000 | 1000 |

| Max. Grain Size of Aggregate (mm) | 5 | 5 |

| Speed of Mixing Blade (r/min) | 26.4 | 21.9 |

| Mixing Blade (PCS) | 6 | 6 |

| Model of Mixing Motor | XWD8-59-15kw | |

| Power of Mixing Motor (KW) | 15 | 15 |

| Model of Winch | 500.3 | ---- |

| Power of Winch (KW) | 4.5kw/i=20.27 | ---- |

| Height of Unloading Material (mm) | 1850 | 1850 |

| Model of Water Pump Motor | 3 phase self-sucking pump | |

| Power of Water Pump Motor | 1.1KW | 1.1KW |

| Frame Dimension in Working | 3900×4728×4382 | 3900×1550×5750 |

| Frame Dimension | 7560×6060×6565 | 7560×3065×6565 |

| Net Weight (T) | 6.2 | 5.5 |

| Parameters | Specifications | |

| KB10 | ||

| Pumping Pressure in Theory (Mpa) | High pressure | 4.5 |

| Low pressure | 2.3 | |

| Transport Capacitry in Theory (m3/h) | High Pressure | 5 |

| Low Pressure | 9.4 | |

| Max. Transport Distance (m) | Horizontal | 300 |

| Vertical | 120 | |

| Main Motor Power (KW) | 11 | |

| Hopper Volume (m3) | 0.1 | |

| Loading Height | 1000 | |

| Hydraulic Oil Tank Volume | 80 | |

| Distribution Valve Form | Ball Valve | |

| Main Machine Weight (KG) | 500 | |

| Frame Size: LXWXH (mm) | 1785×960×1700 | |

| Function | Molding system | |

| Finished Wall Panel Size | 3000×600×75/90/100/150/200mm | |

| Output of Wall Panel with Different Thickness | 75mm | 14 PCS |

| 90mm | 12 PCS | |

| 100mm | 11 PCS | |

| 150mm | 8 PCS | |

| 200mm | 7 PCS | |

| Hydraulic Unit | Motor power | 2.2 KW |

| Operating Pressure | 3-4Mpa | |

| Molding Time | Two Hours (High aluminum cement) | |

| Net Weight | 5 T | |

| Components | Host machine, hydraulic station, mould | |

| Function | Pulling panel out of molds, collecting wall panels together and turning over 90° for easy handling by forklift | |

| Motor Power | Hydraulic Unit Motor | 6.6kw |

| Traveling Motor | 1.5kw | |

| Demoulding Motor | 1.1kw | |

| Cylinder Travel | Wall panel pushing cylinder | 1200mm |

| Turnover Cylinder | 650mm | |

| Weight | 2.2T | |

| Component | Hydraulic unit motor, Turnover Machine, Demoulding Device, Wall | |

| panel pushing device, rail, traveling motor, Electrical control cabinet | ||

| Frame | 4350×3612×1150mm | |

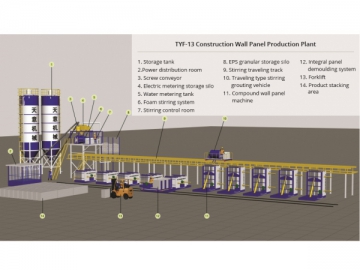

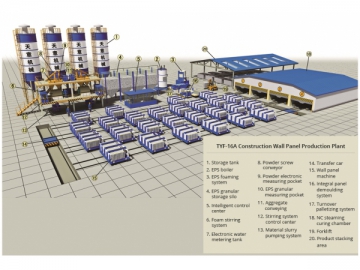

TYF-16A Construction Wall Panel Production Plant (Mobile Type, Calcium Silicate Board Compound Wall, GRC Glass Reinforced Concrete Panel)

wallpanellines.com

TYF-16A Construction Wall Panel Production Plant (Mobile Type, Calcium Silicate Board Compound Wall, GRC Glass Reinforced Concrete Panel)

wallpanellines.com

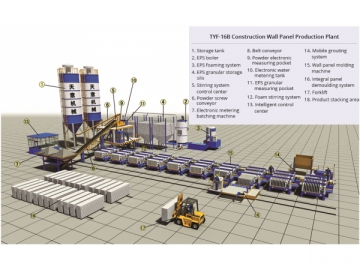

TYF-16B Construction Wall Panel Production Plant (Stationary Type, Calcium Silicate Board Compound Wall, GRC Glass Reinforced Concrete Panel)

wallpanellines.com

TYF-16B Construction Wall Panel Production Plant (Stationary Type, Calcium Silicate Board Compound Wall, GRC Glass Reinforced Concrete Panel)

wallpanellines.com

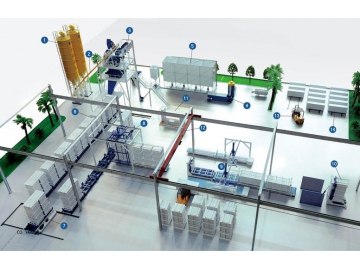

TYFZ16 Construction Wall Panel Production Plant (Vertical Rotating Type, Lightweight Compound Wall Panel)

wallpanellines.com

TYFZ16 Construction Wall Panel Production Plant (Vertical Rotating Type, Lightweight Compound Wall Panel)

wallpanellines.com