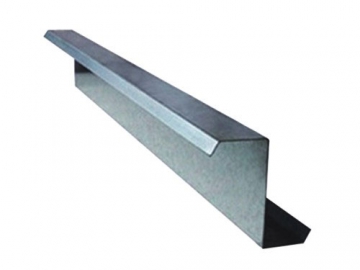

Roll Forming Machine (For C Purlins)

Request a Quote

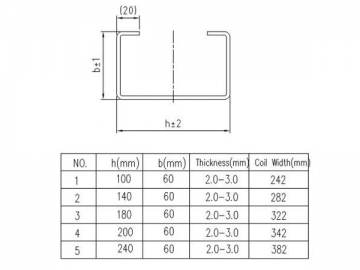

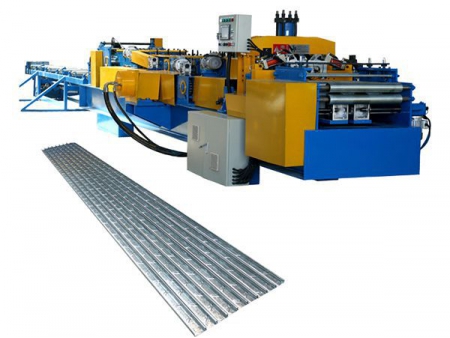

The roll forming machine is used to produce C purlines with width between 100 and 240mm. It supports feeding materials such as cold rolled steel strip and heat treated galvanized steel strip with thickness from 0.5 to 3.0mm.

Technical Data of C Purlin Roll Forming Machine| Suitable material | Cold-rolled steel strip and heat-treated galvanized steel strip |

| Thickness of raw material | 1.5-3.0mm (235-345Mpa) |

| Size of C purlin | 100-240mm adjustable (special size available) |

| Material of roller | Cr12 mould steel with quench treatment, HRC58-60 |

| Material of cutter blade& punching die | Cr12 mould steel with quench treatment, HRC58-60 |

| Material of shaft | High quality 45# steel with heat treatment. Roller grinder milling. |

| Forming speed | about 10-12m/min |

| Power Requirement | Main motor power: 15 Kw (Depend on final design) |

| Hydraulic station power | 5.5Kw (Depend on final design) |

| Diameter of shaft for rollers | 82mm |

| Controlling system | Mitsubishi PLC & converter |

| Quantity of rollers | about 15 stations for main rollers |

| Weight of machine | About 7500KGS |

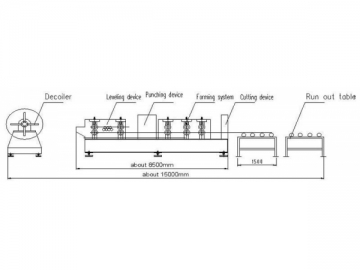

| Machine installation size | About 15mx2.1mx1.4m |

-

Roller is made of Cr12 mould steel with quench treatment. The hardness is about 60HRC. It is also plated with zinc for anti-rust treatment.

-

Different sizes can be formed in the same machine. The punching device is optional.

Related Names

Metal Forming Equipment | Sheet Metal Machinery | Metal Fabrication Equipment

Related products

Send Message

Most Recent

More

Other Products

Videos