DTH Drill Bits

Driven by DTH hammer, the DTH drill bits crush and drill rocks by impacting.

Features- Premium YK05 alloy buttons;

- Premium alloy steel for skirts;

- Skirts are nitriding-processed, featuring better wearing quality;

- Complete sizes and specifications, compatible with most mainstream-branded DTH hammers.

Mining, quarrying, water well drilling, geothermal well drilling, foundation piling, etc.

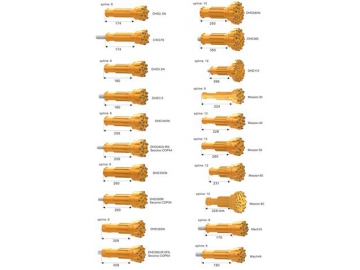

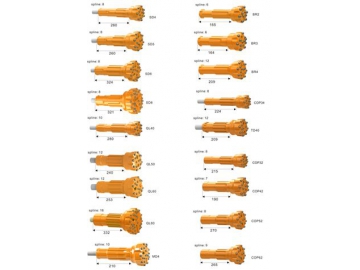

DTH Bits Shank Identification

Flat front: Spherical buttons

Applications: For drilling in hard and abrasive rock

Flat front: Spherical gauge buttons, Ballistic front buttons.

Applications: For drilling in medium hard to hard and moderately abrasive rock.

Convex front: Ballistic

Applications: For drilling at high penetration rates in non abrasive rock.

Concave front: Ballistic

Applications: For drilling in medium hard, maximum hole deviation control.

Hemispherical button Universal buttons for all rock formation, best suited to hardest and very abrasive rocks formation

Parabolic button (semi-ballistic) Excellent penetration rate, but only suited to medium hard and not-very-abrasive rock formation.

Ballistic buttons Similar to parabolic buttons, used for soft to medium hard and not so abrasive rock formation, excellent in penetration rate

| 2 inches DTH hammer button bits | ||||||

| Shank style | Diameter in mm | Flat face | Convex face | Concave face | Approx. weight | Part Number |

| BR 2 | 70 | √ | √ | 2.5kgs | BR2-70 | |

| 76 | √ | √ | 2.6kgs | BR2-76 | ||

| 80 | √ | √ | 2.7 kgs | BR2-80 | ||

| 90 | √ | √ | 3.5 kgs | BR2-90 | ||

| 3 inches DTH hammer button bits | ||||||

| Shank style | Diameter in mm | Flat face | Convex face | Concave face | Approx. weight | Part number |

| 85 | √ | √ | 3.0 kgs | BR3-85 | ||

| 90 | √ | √ | 3.4 kgs | BR3-90 | ||

| BR 3 | 95 | √ | √ | 3.8 kgs | BR3-95 | |

| 100 | √ | √ | √ | 4.5 kgs | BR3-100 | |

| 105 | √ | √ | √ | 5.2 kgs | BR3-105 | |

| 85 | √ | √ | 3.6kgs | Mach33-85 | ||

| 90 | √ | √ | 3.7 kgs | Mach33-90 | ||

| Mach 303 | 95 | √ | √ | 4.0 kgs | Mach33-95 | |

| 100 | √ | √ | √ | 4.5 kgs | Mach33-100 | |

| 105 | √ | √ | √ | 5.5 kgs | Mach33-105 | |

| 85 | √ | √ | 5.0 kgs | DHD3.5-85 | ||

| 90 | √ | √ | 5.8 kgs | DHD3.5-90 | ||

| DHD3.5 | 95 | √ | √ | 5.9 kgs | DHD3.5-95 | |

| 100 | √ | √ | √ | 6.1 kgs | DHD3.5-100 | |

| 105 | √ | √ | √ | 6.3 kgs | DHD3.5-105 | |

| 85 | √ | √ | 4.5 kgs | COP32-85 | ||

| 90 | √ | √ | 4.6 kgs | COP32-90 | ||

| COP 32 | 95 | √ | √ | 4.7 kgs | COP32-95 | |

| 100 | √ | √ | √ | 4.8 kgs | COP32-100 | |

| 105 | √ | 4.9 kgs | COP32-105 | |||

| 85 | √ | √ | 5.0 kgs | COP34-85 | ||

| 90 | √ | √ | 5.7kgs | COP34-90 | ||

| COP 34 | 95 | √ | √ | 5.8 kgs | COP34-95 | |

| 100 | √ | √ | √ | 6.0 kgs | COP34-100 | |

| 105 | √ | √ | √ | 6.2 kgs | COP34-105 | |

| 85 | √ | √ | 4.6 kgs | Mission30-85 | ||

| 90 | √ | √ | 4.7 kgs | Mission30-90 | ||

| Mission 30 | 95 | √ | √ | 4.9 kgs | Mission30-95 | |

| 100 | √ | √ | √ | 5.3 kgs | Mission30-100 | |

| 105 | √ | √ | √ | 5.4 kgs | Mission30-105 | |

| 5 inches DTH hammer button bits | ||||||

| Shank style | Diameter in mm | Flat face | Convex face | Concave face | Approx. weight | Part number |

| 135 | √ | √ | √ | 16.2 kgs | DHD350-135 | |

| 140 | √ | √ | √ | 16.5 kgs | DHD350-140 | |

| DHD350R | 146 | √ | √ | √ | 17.0 kgs | DHD350-146 |

| 152 | √ | √ | √ | 17.8 kgs | DHD350-152 | |

| 165 | √ | √ | √ | 18.5 kgs | DHD350-165 | |

| 135 | √ | √ | √ | 16.0 kgs | MACH50-135 | |

| 140 | √ | √ | √ | 16.5 kgs | MACH50-140 | |

| MACH50 | 146 | √ | √ | √ | 17.8 kgs | MACH50-146 |

| 152 | √ | √ | √ | 18.0 kgs | MACH50-152 | |

| 165 | √ | √ | √ | 18.5 kgs | MACH50-165 | |

| 135 | √ | √ | √ | 16.2 kgs | QL50-135 | |

| 140 | √ | √ | √ | 16.6 kgs | QL50-140 | |

| QL 50 | 146 | √ | √ | √ | 17.1 kgs | QL50-146 |

| 152 | √ | √ | √ | 17.8 kgs | QL50-152 | |

| 165 | √ | √ | √ | 18.0 kgs | QL50-165 | |

| 135 | √ | √ | √ | 14.0 kgs | Mission50-135 | |

| 140 | √ | √ | √ | 15.0 kgs | Mission50-140 | |

| Mission 50 | 146 | √ | √ | √ | 16.0 kgs | Mission50-146 |

| 152 | √ | √ | √ | 17.1 kgs | Mission50-152 | |

| 165 | √ | √ | √ | 18.0 kgs | Mission50-165 | |

| 135 | √ | √ | √ | 14.5 kgs | SD5-135 | |

| 140 | √ | √ | √ | 15.5 kgs | SD5-140 | |

| SD 5 | 146 | √ | √ | √ | 16.5 kgs | SD5-146 |

| 152 | √ | √ | √ | 18.0 kgs | SD5-152 | |

| 165 | √ | √ | √ | 19.0 kgs | SD5-165 | |

| 6 inches DTH hammer button bits | ||||||

| Shank style | Diameter in mm | Flat face | Convex face | Concave face | Approx. weight | Part number |

| DHD360 | 152 | √ | √ | √ | 23.3kgs | DHD360-152 |

| 165 | √ | √ | √ | 25.2 kgs | DHD360-165 | |

| 171 | √ | √ | √ | 25.8 kgs | DHD360-171 | |

| 190 | √ | √ | √ | 28.5 kgs | DHD360-190 | |

| 203 | √ | √ | √ | 29.5 kgs | DHD360-203 | |

| 152 | √ | √ | √ | 22.3 kgs | QL60-152 | |

| 165 | √ | √ | √ | 24.4kgs | QL60-165 | |

| QL 60 | 171 | √ | √ | √ | 24.8 kgs | QL60-171 |

| 190 | √ | √ | √ | 29.0 kgs | QL60-190 | |

| 203 | √ | √ | √ | 33.0 kgs | QL60-203 | |

| 152 | √ | √ | √ | 21.8 kgs | Mission60-152 | |

| 165 | √ | √ | √ | 23.5 kgs | Mission60-165 | |

| Mission 60 | 171 | √ | √ | √ | 25.0 kgs | Mission60-171 |

| 190 | √ | √ | √ | 27.0 kgs | Mission60-190 | |

| 203 | √ | √ | √ | 29.1 kgs | Mission60-203 | |

| 152 | √ | √ | √ | 27.0 kgs | SD6-152 | |

| 165 | √ | √ | √ | 28.0 kgs | SD6-165 | |

| SD 6 | 171 | √ | √ | √ | 31.0 kgs | SD6-171 |

| 190 | √ | √ | √ | 33.0 kgs | SD6-190 | |

| 203 | √ | √ | √ | 35.0 kgs | SD6-203 | |

| 8 inches DTH hammer button bits | ||||||

| Shank style | Diameter in mm | Flat face | Convex face | Concave face | Approx. weight | Part number |

| 203 | √ | √ | 48.1 kgs | DHD380-203 | ||

| 216 | √ | √ | 52.0 kgs | DHD380-216 | ||

| DHD380 | 241 | √ | √ | 58.7kgs | DHD380-241 | |

| 254 | √ | √ | 60.4 kgs | DHD380-254 | ||

| 292 | √ | √ | 80.1 kgs | DHD380-292 | ||

| 305 | √ | √ | 83.5kgs | DHD380-305 | ||

| 203 | √ | √ | 48.5 kgs | QL80-203 | ||

| 216 | √ | √ | 50.1 kgs | QL80-216 | ||

| QL 80 | 241 | √ | √ | 60.1 kgs | QL80-241 | |

| 254 | √ | √ | 62.5 kgs | QL80-254 | ||

| 292 | √ | √ | 85.0 kgs | QL80-292 | ||

| 305 | √ | √ | 83.9 kgs | QL80-305 | ||

| 203 | √ | √ | 41.0 kgs | Mission80-203 | ||

| 216 | √ | √ | 42.0 kgs | Mission80-216 | ||

| Mission 80 | 241 | √ | √ | 56.0 kgs | Mission80-241 | |

| 254 | √ | √ | 57.0 kgs | Mission80-254 | ||

| 292 | √ | √ | 71.5 kgs | Mission80-292 | ||

| 305 | √ | √ | 77.0 kgs | Mission80-305 | ||

| 203 | √ | √ | 42.0 kgs | SD8-203 | ||

| 216 | √ | √ | 54.0 kgs | SD8-216 | ||

| SD 8 | 241 | √ | √ | 63.0 kgs | SD8-241 | |

| 254 | √ | √ | 67.0 kgs | SD8-254 | ||

| 292 | √ | √ | 85.0 kgs | SD8-292 | ||

| 305 | √ | √ | 94.0 kgs | SD8-305 | ||

- 1. Diameters above are only our standard configurations, other diameters are also available upon request.

- 2. The unit weight for each size is for reference only.

- 3. Face design, buttons shape, buttons configuration and flushing holes number must be confirmed when confirming the order.

- 4. Please be cautious when ordering bigger-diameter button bits since they might be oversized.

Our rock drilling equipment can be applied in various industries, doing rock drilling and crushing duties for digging, blasting, etc.

We mainly offer 4 series of rock drilling tools: top hammer drilling tools, down-the-hole (DTH) drilling tools, self-drilling anchor system and drag bits.