Middle Speed Paper Container / Dining Bowl Forming Machine (75-85 piece/min, 16-46oz Paper Bowl)

The middle speed paper container/dining bowl forming machine with production speed of 75~85pcs/min and capacity of 16~46oz(145~1334ml), which has widespread use on the production of paper bowl for instant noodles, soup, etc.

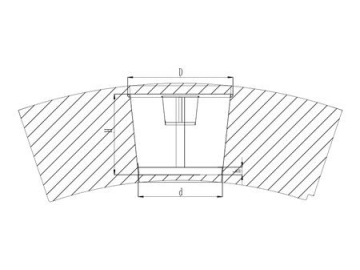

Common type: H: 40-135 h: 3-15 D: 115-150 d: 85-120 Lengthen type: H: 40-180 h: 3-15 D: 115-150 d: 85-120

Common type: H: 40-135 h: 3-15 D: 115-150 d: 85-120 Lengthen type: H: 40-180 h: 3-15 D: 115-150 d: 85-120| Paper cup capacity | 16-46oz |

| Paper cup dimension | (D)φ115-150mm (H)40-180mm (d)φ85-120mm (h)3-15mm |

| Production speed | 75-85pcs/min |

| Weight | 4500 kg |

| Power supply | three-phase 380V |

| Total power | 21.6KW |

| Air consumption | 0.4cube/min |

| Dimension of machine | L2565*W1775*H1600mm Lengthen type:L2795*W2025*H1600mm |

| Dimension of collecting table | |

| Paper gram weight | 210-350gsm(optional) |

| Paper type | single PE/double PE(optional) |

| Inspecting equipment | ordered separately |

| Paper sheet conveyor | ordered separately |

| Control panel | 7 inch |

Molds

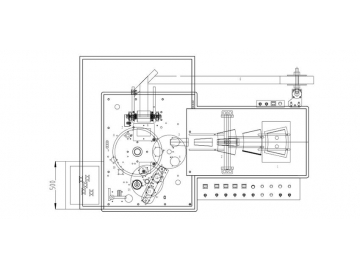

Molds Gear transmission device

Gear transmission device Control cabinet

Control cabinet  Paper money mold control system

Paper money mold control system  Paper sheet feeding system

Paper sheet feeding system  Ultrasonic heating device for side wall sealing and conglutination of fan-shaped paper sheet

Ultrasonic heating device for side wall sealing and conglutination of fan-shaped paper sheet

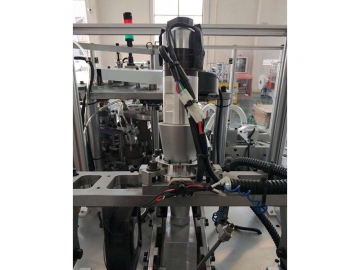

1. Integral type mould base frame

Most of equipment adopt non-integral type mould base frame structure and have the problem of less enough precision. Discover Machinery adopts integral type mould base frame design, which has very high precision and longer service life.

2. Manipulator cup transferring mechanism

Traditionally, paper cup adopts free-falling method in the machining process. Now, we improve this method with three clear steps of cup receiving, overturning and cup lifting, which can improve production rate and stability during the manufacturing process greatly.

3. Gear transmission

The paper container forming machine adopts gear transmission mechanism and is not easy to dislocated. It is beneficial for more stable working state especially for continuous production.

4. Open-type indexing box

Our paper container machine is equipped with open-type indexing box, which is featured as higher precision, quicker speed, and also more convenient for maintenance.

5. Paper cup bottom heating system

As we all know, bottom heating before curling and forming of paper cup is a very important procedure. We adopt Switzerland Leister heating device ensuring heating process is very stable.

6. Oil lubricating system

In order to ensure paper cup machine in good lubrication condition in the working process, timing and quantitative lubricating oil can be realized by automatic program controlling.

7. Integral base frame design

The whole machine is designed with box structure and is easy for operation and maintenance.

Our company is specialized in manufacturing disposable paper cup/container machines, we are a leading recycle paper container manufacturer, offer paper cup forming machine for coffee cup makers and water paper cup makers, and offer paper dining bowl making machine since 1998, we have made completed lines for making quality disposable paper cup and bowl machines, also we are offering the custom molds to match the machines.

Index

paper cup machine, paper container machine, paper cup making machine, coffee cup machine