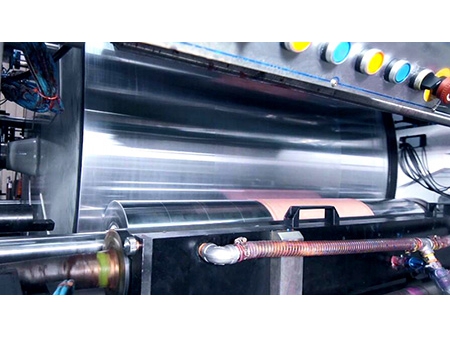

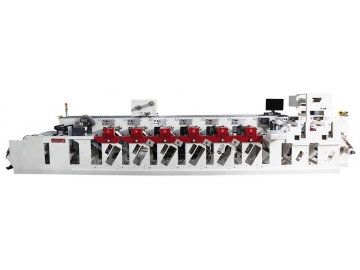

Flexo Printing Press

This SZIND flexo printing press is driven by gear transmission, with registration method by changing driving gear.

We have two standard types of gear driven flexo printing presses for you to choose from. If you have specific requirements, custom-engineered flexo printing machine is also available.

Standard print width: 800/1200/1600mm (can be customized, Max. 4200mm)

Specifications

Max. printing speed: 220m/min

Roll diameter: 121mm to 261mm

Max. repeat length: 380mm to 820mm

Tension control precision: ±2N

Specifications

Max. printing speed: 150m/min

Roll diameter: 121mm to 261mm

Max. repeat length: 380mm to 820mm

Tension control precision: ±2N

1. The unwind unit has double shafts which are driven by dual-motor, it facilitates operation and saves both material and time.

2. Three pneumatic cylinders are used for web splicing, with closed loop dancer tension control.

3. Designed with functions of initiative unwinding by inverter motor, automatic measuring of the roll diameter, adhesive tape detecting, etc.

1. The rewind unit has double shafts which are driven by dual-motor. Alarm will be activated when presets are reached, and operator is informed to quick change rolls. Automatic closed loop dancer tension control makes that roll changing automatically synchronizes machine speed.

2. By using closed loop dancer roll tension control and equipping with nip roll, the consistency of web tension can be maintained, enabling an optimal roll surface.

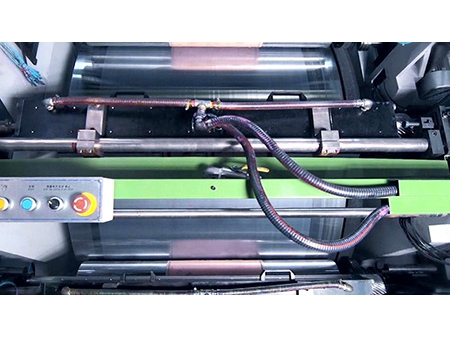

1. The infeed nip unit consists of a steel roller and a rubber roller for web pulling. And it designed with edge position control for web guiding.

2. Steel nip roller is driven by an independent servo motor having a variable speed drive, which is used in measuring the tension of web by dancer roll potentiometer, and used in closed loop tension control by PLC terminal.

3. Rubber nip roller is pneumatically activated with dual pneumatic cylinders, with self-locking function.

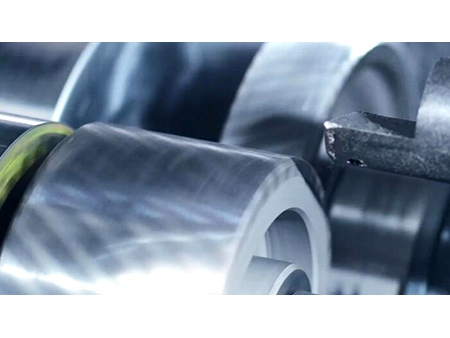

1. Printing plate is processed by well-known brand machining center, processing accuracy is guaranteed.

2. Ink tray is made of stainless steel coated with Teflon for better anticorrosive performance.

3. Using round-tooth timing belt with high precision bevel gear.

4. Ink is scraped by chambered doctor blade with ceramic anilox roll. Ink circulating is implemented by double diaphragm pump

5. Central impression cylinder is driven by main servo motor, adjustable rollers in horizontal or vertical position are placed in front of central impression cylinder.

6. Equipped with drying fan, it works automatically when machine starts run and turns off when machine shuts down.

1. Drying tunnel is designed with external bearing and guide roller, avoiding abnormal operations caused by heat deformation of bearing.

2. Drying hood is pneumatically opened and closed. With a design of negative pressure inside the drying tunnel, hot air can be prevented from escaping, thus achieving automatic control of internal temperature.

Ink viscosity control——This unit aims at automatically measuring and regulating of ink and solvent, facilitating follow-up operations.

Printing plate mounting machine ——This machine can be used when printing substrates are soft, it helps reducing machine tension which generates pulling force on substrates.

European brand doctor blade——Chambered doctor blades from European brands have excellent air humidity resistance, avoiding blade being corroded.

Corona treater——This corona treatment unit increases the adhesion of substrate surfaces.

European brand central impression cylinder