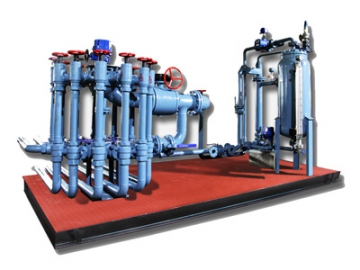

Multi-well Oil and Gas Metering Device

Request a Quote

Multi-well oil and gas metering device is particularly designed for using in oilfields where oil and gas pipeline network is complex. The aim of the device is to improve the process of oil and gas gathering and transmission on the basis of conventional metering device. This oil and gas metering device is capable of metering fluids from multiple wells, greatly reducing production consumptions and decreasing production cost. Through combining the principle of cyclonic separation and gravity separation, and equipping with single-phase meter, the multi-well oil and gas metering device significantly improves separation efficiency and measurement precision while ensures the reliability and stability of the device.

Features

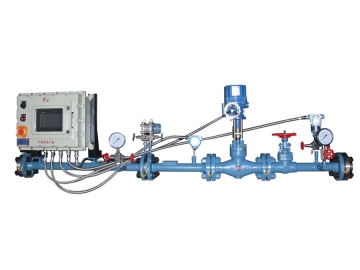

- Skid-mounted construction, small footprint, easy operation, high metering precision, low maintenance and unmanned operation;

- Self-compensating seal is tightly aligned against inner wall of valve body, and the parts are adjusted manually to facilitate installation and maintenance, realizing zero leakage;

- Combination of photoelectric switch and Hall Effect proximity switch guarantees high precision of well positioning with zero error;

- Sealing surfaces adopts STL tungsten carbide to provide excellent performance in corrosion resistance, wear resistance and less scaling;

- Low pressure loss, the maximum pressure loss of the entire system is less than 0.025MPa;

- Adopting multi-stage separation technology, the solid-liquid separation function assists in separating oil sands from crude oil; Vortex separation provides an excellent oil-gas separation effect in gas-liquid separation of crude oil, achieving the process of continuous metering of gas and liquid;

- Sand removal and filtration unit is equipped to solve the problem of pipeline blockage caused by high contents of sand and wax in the oil, and simultaneously enhance the metering precision and stability;

- Stable metering precision will not be affected by the types of oil and gas; Measuring range is wide, liquid phase measuring range can reach over 1:15;

- Pipe pump is outfitted to avoid issues such as low measurement accuracy and no liquid output;

- Emergency bypass circuit will be automatically opened when the pressure failure occurs or the power is off, protecting the pipeline from accidents caused by fault pressure;

- Utilizing single-phase meter to measure multiphase flow mixed density, and the flow parameters of multiphase fluids can be accurately modulated through in-line temperature compensation and pressure compensation, thus improving the metering accuracy;

- Control panel is configured with metering control system and communication equipment, providing the functions of on-site or remote operation and monitoring; The metering control system has MODBUS 232/485 interface and RJ45 interface, the data transmission is implemented in accordance with MODBUS 485 protocol and MODEBUS TCP/IP protocol; Wireless communication technology is adopted in SCADA system of central control room at oilfield operation area to achieve remote metering control and remote monitoring;

Related products

Send Message

Most Recent

More

Other Products

Videos