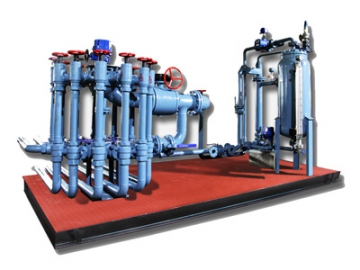

Water Distribution Device for Multi Oil Wells, High Pressure

Request a Quote

High pressure water distribution device is successfully developed thanks to our technical knowledge and nearly two decades of accumulated experience in the aspect of industrial field instruments, especially constant engineering and improvement in process instrumentation for oil industry. We pride ourselves in our expertise and in-depth knowledge in sector of multiphase flow. Based on the static mixer with low loss of viscosity, our high pressure water distribution device is engineered and manufactured by taking advantages of existing technologies coupled with multi-well water injection process.

Features

- Small footprint, easy operation, high metering precision, high reliability, low maintenance and unmanned operation;

- Small footprint, easy operation, high metering precision, high reliability, low maintenance and unmanned operation;

- Standard modular design, interchangeable parts for every single well; Compact and elegant installation structure of pipelines and valves, which enables procedures of procurement, maintenance and repair easier;

- The pressure and flow rate of each node will be displayed on-site and remotely, and the device is designed with functions of flow rate modulating and under-pressure & over-pressure alarm;

- Flow meter is detachable, the entire flow meter is not required to be removed from pipeline, maintenance personnel only need to remove the core part for repairing or replacing, thus providing great convenience for maintenance operation while significantly reducing the quantity of spare instruments;

- Static mixer has a specially designed structure which makes medium to be mixed uniformly and completely, and the viscosity loss of the medium can be minimized;

- Intelligent flow rate measurement and control unit has an integrated structure that is made through forging process, resulting high modulating precision and excellent erosion resistance while achieving manual or automatic modulating of flow rate for every single well;

- Control panel is placed at the same skid where the device is installed, allowing the parameter setting and date logging to be accomplished simultaneously, as well as achieving remote data transmission and remote flow rate modulating;

Related products

Send Message

Most Recent

More

Other Products

Videos