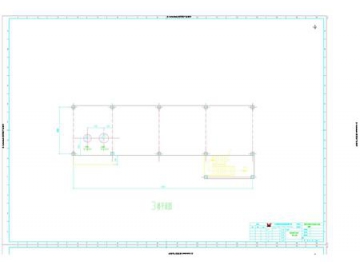

Formaldehyde Plants with Off-Gas Circulation

Formaldehyde plants with off-gas circulation are a traditional formaldehyde production technology. After educating ourselves on a number of reboiler processes from around the world, we optimized the process, equipment, and automation levels to simplify operations. The production capacity is 60TPD-200TPD. The concentration can be flexibly changed to range between 37 to 42%. Helipont has produced hundreds of this particular formaldehyde plant type.

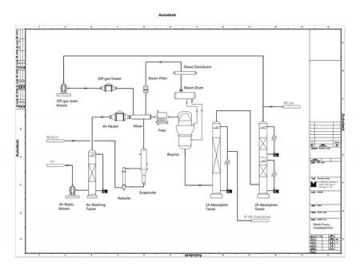

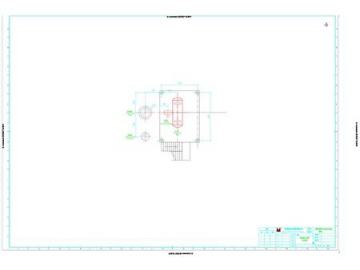

- Air roots blower

- Air washing tower

- Reboiler

- Evaporator

- Off-gas roots blower

- Off-gas heater

- Air Heater

- Mixer

- Evaporator

- Steam Filter

- Filter

- Reactor

- Steam Drum

- Steam Distributor

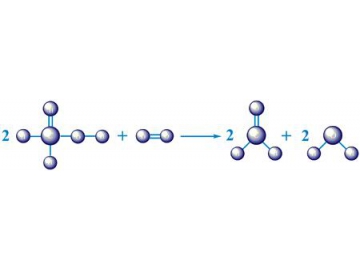

The filtered methanol liquid enters the methanol evaporator, then travels to the methanol evaporator, in which we separate the gas and liquid and facilitate gas entering the mixer. After filtering, washing and heating, air enters the mixer, and steam enters after filtration. The circulation off gas from the top of absorber 2# will enter the mixer after heating.

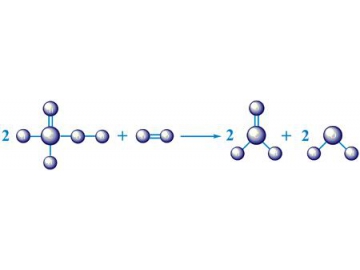

The above 4 gas types, after a complete mixing process, will go through one least filtration, then enter the methanol reactor, where a redox reaction occurs to generate formaldehyde gas. This gas from the reactor includes steam, nitrogen, oxygen and hydrogen. It then requires a secondary absorption process in order to obtain a formaldehyde solution. We use two independent absorbers. After complex absorption and heat exchange, we obtain the formaldehyde solution. In addition, the off gas is discharged from the top of absorber 2#. Part of the off gas goes into the off-gas roots blower for circulation and the other enters the furnace for burning, and will obtain steam under a variety of pressure.

Product Specifications| Component | Index |

| Formaldehyde | 37-42% |

| Methanol | ≤1 wt. % |

| Formic Acid | ≤0.01 g/100 mL |

| Chloride | ≤0.0025 g/100 mL |

| Ashes | ≤0.01 g/100 mL |

| Particular | Index | Remark |

| Feedstock & Auxiliaries | ||

| Methanol(99.5%) | 0.445 ton for per ton of 37% formalin product | Expectation:442 ton |

| Catalyst (Silver) | As-per the Capacity | |

| Civil Utilities | ||

| Circulating Cooling Water | 40 ton for per ton of 37% formalin product | |

| Desalted Water | As-per the process | |

| Power Electricity (Voltage:415/250V; Frequency 50±0.5Hz) | 28 KWh for per ton of 37% formalin product | With 200kvA transformer |

| Steam for Startup(0.2Mpa) | 900kg/h | Need 3~4hrs |

| Export Steam as By-product(0.25MPa) | 0kg per ton of 37% formalin product | Without the Off-gas Boiler |

| Instrumental Air (P=0.5-0.7MPa(G)) | As-per the Capacity |

Projects Were Work on