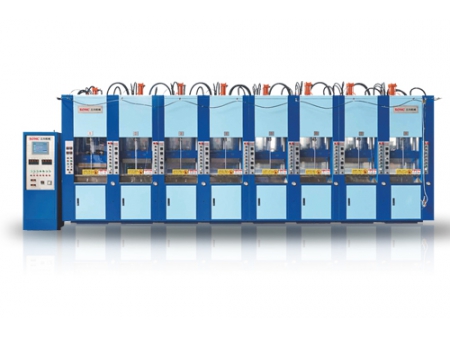

Rubber Tyre Injection Moulding Machine, ZH108R

Request a Quote

Multi-station injection moulding machine for producing rubber tyres and rubber handrails

This injection moulding machine is suitable for processing rubber particles and then produce rubber products like low-speed tyres and rubber handrails.

Specifications

| Stations | 8 | |

| Maximum injection volume | g | 3500 |

| Screw diameter | mm | 80 |

| Injection pressure | MPa | 100 |

| Clamping force | Ton | 500 |

| Mould space | mm | 850*850*300 |

| Die opening stroke | mm | 600 |

| Dimensions | mm | 13000*6000 |

| Heating power | kW | 30 |

| Total power | kW | 75 |

| Total weight | Ton | 100 |

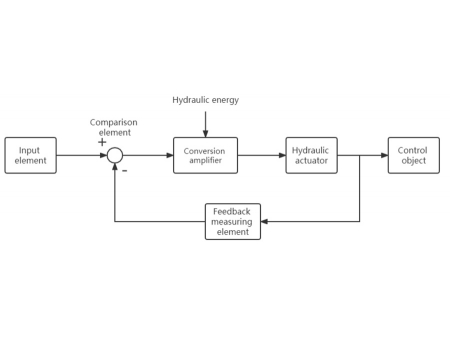

Optional System flow chart

-

Suction machine

-

Energy-saving hydraulic servo control system

Features

- No need for rubber mixing, direct injection molding of rubber particles;

- Rubber particles do not age for up to 6 months, and the products made of the rubber particles are wear-resistant and high-elastic;

- This injection moulding machine features large injection pressure and clamping force, which ensure the product is smooth and free of burrs;

- Standard industrial human-machine interface (HMI) and PLC control system are installed;

- This tyre injection moulding machine has a powerful vacuum system to remove the air in the mould cavity;

- Constant mold temperature control system is configured to ensure precise control of vulcanization speed;

- This rubber tyre injection moulding machine has a precise displacement control system to improve the working efficiency of the injector;

- Fully meet the demands of the vulcanization production of rubbers;

Auxiliary Equipment

-

Cooling tower cools down hydraulic oil and raw materials before they are fed into the injection moulding machine;

-

Air compressor can be connected to the injection moulding machine to ensure enough air supply;

-

Drying system helps avoid bubbles in finished rubber products;

Related products

Send Message

Most Recent

More

Other Products

Videos