Get in touch with us

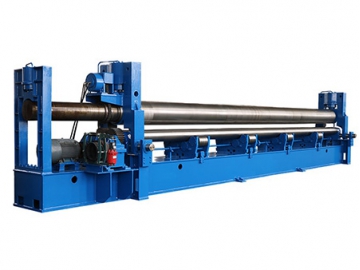

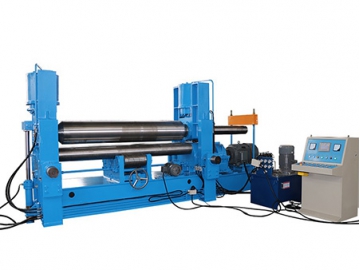

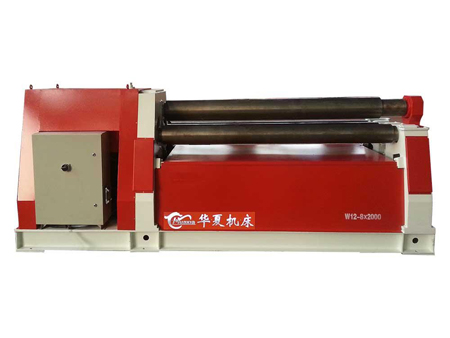

Mechanical Plate Bending Machine

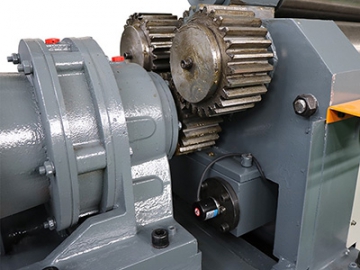

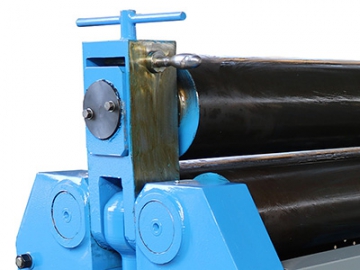

The mechanical plate bending machine is a 3-roller symmetrical plate rolling machine. The upper roller does vertical movement at the central position of the two lower rollers, while the two lower rollers operate in rotary motion. These two lower rollers are main drive rollers which rotate by the meshing between the reducer output gear and the lower roller to provide torque for the bending plate.

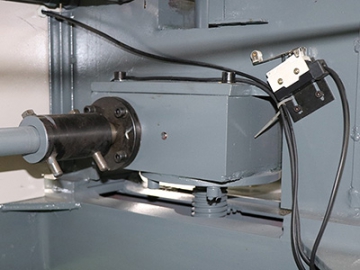

The vertical movement of the top roller is controlled by a separate transmission system, it is transmitted by screw nut and worm gear.

This mechanical plate bending machine can be configured with various profile bending molds to roll a variety of profiles, such as steel angle, steel flat bar, H-channel, steel rod. The cone rolling unit can also be added to roll cone-shaped workpieces.

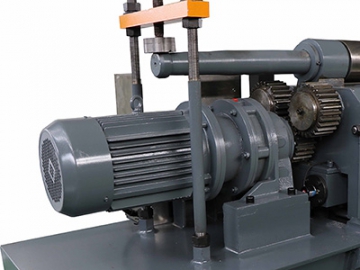

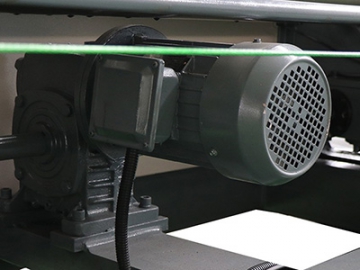

Main drive motor

Main drive motor  Gear

Gear  Motor of top roller

Motor of top roller  Limit switch

Limit switch  Control console

Control console  Tilting frame

Tilting frame

Profile bending molds

Profile bending molds  Cone rolling unit

Cone rolling unit  Hydraulic tilting frame

Hydraulic tilting frame  Perimeter safety wire

Perimeter safety wire

| Model | W11-4x1500 | W11-4x2000 | W11-4x2500 | W11-6x2500 | W11-6x3000 | W11-8x2000 |

| Max. rolling thickness(mm) | 4 | 4 | 4 | 6 | 6 | 8 |

| Max. rolling width(mm) | 1500 | 2000 | 2500 | 2500 | 3000 | 2000 |

| Min. rolling diameter at full loading(mm) | 230 | 350 | 400 | 500 | 500 | |

| Yielding limited(Mpa) | 245 | 245 | 245 | 245 | 245 | 245 |

| Upper roller diameter(mm) | 150 | 160 | 170 | 185 | 220 | 185 |

| Lower roller diameter(mm) | 130 | 140 | 160 | 170 | 180 | 170 |

| Central distance between lower rollers(mm) | 200 | 220 | 260 | 260 | 280 | 260 |

| Main motor power(KW) | 3 | 4 | 5.5 | 5.5 | 5.5 | 5.5 |

| Model | W11-8x2500 | W11-10x3000 | W11-12x2000 | W11-12x2500 | W11-12x3000 | W11-16x2500 |

| Max. rolling thickness(mm) | 8 | 10 | 12 | 12 | 12 | 16 |

| Max. rolling width(mm) | 2500 | 300 | 2000 | 2500 | 3000 | 2500 |

| Min. rolling diameter at full loading(mm) | 600 | 850 | 550 | 600 | 700 | 700 |

| Yielding limited(Mpa) | 24 | 245 | 24 | 245 | 245 | 245 |

| Upper roller diameter(mm) | 240 | 260 | 240 | 260 | 280 | 280 |

| Lower roller diameter(mm) | 200 | 220 | 200 | 220 | 240 | 250 |

| Central distance between lower rollers(mm) | 300 | 320 | 300 | 320 | 360 | 360 |

| Main motor power(KW) | 7.5 | 11 | 7.5 | 11 | 15 | 15 |

| Model | W11-20x2000 | W11-20x2500 | W11-20x3000 | W11-25x2500 |

| Max. rolling thickness(mm) | 20 | 20 | 20 | 25 |

| Max. rolling width(mm) | 2000 | 2500 | 3000 | 2500 |

| Min. rolling diameter at full loading(mm) | 700 | 800 | 900 | 1000 |

| Yielding limited(Mpa) | 245 | 245 | 245 | 245 |

| Upper roller diameter(mm) | 280 | 340 | 360 | 360 |

| Lower roller diameter(mm) | 250 | 260 | 260 | 300 |

| Central distance between lower rollers(mm) | 360 | 440 | 480 | 480 |

| Main motor power(KW) | 15 | 18.5 | 22 | 22 |