Slag Crushing and Grinding Plant

Request a Quote

Introduction

Capacity: 300~1,000 thousand tons/year

Feed Material Size: 2 mm~10 mm

Feed Material: Powdered material like feldspar, calcite, steatite, barite, fluorite, tombarthite, marble, ceramics, bauxite, manganese ore and phosphorus rock.

SINOMALY specializes in offering slag powder production line design, including the design, production and delivery of the vertical mill, installation of equipment sets, and general contracting of the production line construction.

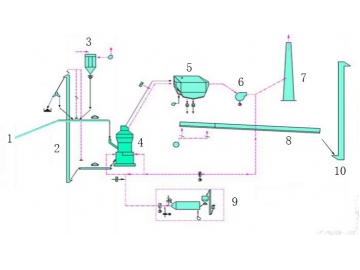

Process: Slag Drying Machine → Extrusion Press→ Agglomerator →Powder Separator (Fine Powder) →Superfine Grinding Mill → Finished Product

- Slag stack

- Feeding equipment

- Conveyer belt

- Vibrating screen

- Vertical mill

- Products collection

- Warehousing management system

- External circulation system

- Hot-blast stove system

- Slag feeding equipment

- Elevator

- Dust collector

- Vertical mill

- Powder collector

- Fan

- Funnel

- Conveyer belt

- Hot-blast stove

- Finished product storage

- The stacked slag is taken and fed by the forklift, and conveyed using the the belt conveyor.

- The slag is transported by the elevator into the vertical mill for grinding. The slag powder is then collected by the powder separator, and dried using a hot blast stove.

- The dried slag powder is transported into the vertical mill for regrinding, after which the slag powder will be collected using a powder separator, then the qualified powder is moved to the finished product warehouse.

150 thousand tons/year slag powder production line

| Equipment | Parameters |

| LRMS22.2 vertical mill for slag | Capacity: ≥20t/h, Specific surface area of product: ≥420m2/kg, Power: 630kW |

| Hot-blast stove | Heating capacity: 0.4×107 kcal/h |

| Dust collector | Airflow: 80000 m³/h, Filter area: 1594 m2 Filtration velocity: 0.80~0.85 m/min Inlet dust concentration: ≤800g /Nm3 Outlet dust concentration: ≤30mg/Nm3 |

| Fan | Total pressure: 7200 Pa Airflow: 80000 m3/h Power: 220 kW |

200 thousand tons/year slag powder production line

| Equipment | Parameters |

| LRMS25.2 vertical mill for slag | Capacity: ≥28t/h, Specific surface area of product: ≥420m2/kg, Power: 900kW |

| Hot-blast stove | Heating capacity: 0.5×107 kcal/h |

| Dust collector | Airflow: 112000 m³/h, Filter area: 2196 m2 Filtration velocity: 0.80~0.850.80m/min Inlet dust concentration: ≤800g /Nm3 Outlet dust concentration: ≤30mg/Nm3 |

| Fan | Total pressure: 7200 Pa; Airflow: 112000 m3/h Power: 315kW |

300 thousand tons/year slag powder production line

| Equipment | Parameters |

| LRMS36.3 vertical mill for slag | Capacity: ≥45 t/h, Specific surface area of product: ≥420m2/kg, Power: 1600 kW |

| Hot-blast stove | Heating capacity: 0.9×107 kcal/h |

| Dust collector | Airflow: 180000 m³/h, Filter area: 3659 m2 Filtration velocity: 0.80~0.85 m/min Inlet dust concentration: ≤800g /Nm3 Outlet dust concentration: ≤30mg/Nm3 |

| Fan | Total pressure: 7200 Pa; Airflow: 180000 m3/h Power: 500 kW |

450 thousand tons/year slag powder production line

| Equipment | Parameters |

| vertical mill for slag | Capacity: ≥65 t/h, Specific surface area of product: ≥420m2/kg, Power: 2000 kW |

| Hot-blast stove | Heating capacity: 1.3×107 kcal/h |

| Dust collector | Airflow: 260000 m³/h, Filter area: 5352 m2 Filtration velocity: 0.80~0.85 m/min Inlet dust concentration: ≤800g /Nm3 Outlet dust concentration: ≤30mg/Nm3 |

| Fan | Total pressure: 7200 Pa; Airflow: 260000 m3/h Power: 710 kW |

500 thousand tons/year slag powder production line

| Equipment | Parameters |

| LRMS38.3 vertical mill for slag | Capacity: ≥75 t/h, Specific surface area of product: ≥420m2/kg, Power: 2500 kW |

| Hot-blast stove | Heating capacity: 1.5×107 kcal/h |

| Dust collector | Airflow: 300000 m³/h, Filter area: 6116 m2 Filtration velocity: 0.80~0.85 m/min Inlet dust concentration: ≤800g /Nm3 Outlet dust concentration: ≤30mg/Nm3 |

| Fan | Total pressure: 7200 Pa; Airflow: 300000 m3/h Power: 800 kW |

600 thousand tons/year slag powder production line

| Equipment | Parameters |

| LRMS43.3 vertical mill for slag | Capacity: ≥90 t/h, Specific surface area of product: ≥420m2/kg, Power: 3150 kW |

| Hot-blast stove | Heating capacity: 1.8×107 kcal/h |

| Dust collector | Airflow: 360000 m³/h, Filter area: 7319 m2 Filtration velocity: 0.80~0.85 m/min Inlet dust concentration: ≤800g /Nm3 Outlet dust concentration: ≤30mg/Nm3 |

| Fan | Total pressure: 7200 Pa; Airflow: 360000 m3/h Power: 1000 kW |

800 thousand tons/year slag powder production line

| Equipment | Parameters |

| LRMS46.3 vertical mill for slag | Capacity: ≥115 t/h, Specific surface area of product: ≥420m2/kg, Power: 3550 kW |

| Hot-blast stove | Heating capacity: 2.3×107 kcal/h |

| Dust collector | Airflow: 460000 m³/h, Filter area: 8782 m2 Filtration velocity: 0.80~0.85 m/min Inlet dust concentration: ≤800g /Nm3 Outlet dust concentration: ≤30mg/Nm3 |

| Fan | Total pressure: 7200 Pa; Airflow: 460000 m3/h Power: 1250 kW |

900 thousand tons/year slag powder production line

| Equipment | Parameters |

| LRMS50.3 vertical mill for slag | Capacity: ≥130 t/h, Specific surface area of product: ≥420m2/kg, Power: 4000 kW |

| Hot-blast stove | Heating capacity: 2.6×107 kcal/h |

| Dust collector | Airflow: 520000 m³/h, Filter area: 10873 m2 Filtration velocity: 0.80~0.85 m/min Inlet dust concentration: ≤800g /Nm3 Outlet dust concentration: ≤30mg/Nm3 |

| Fan | Total pressure: 7200 Pa; Airflow: 520000 m3/h Power: 1400 kW |

1 million tons/year slag powder production line

| Equipment | Parameters |

| LRMS53.3 vertical mill for slag | Capacity: ≥140 t/h, Specific surface area of product: ≥420m2/kg, Power: 4500 kW |

| Hot-blast stove | Heating capacity: 2.8×107 kcal/h |

| Dust collector | Airflow: 560000 m³/h, Filter area: 10873 m2 Filtration velocity: 0.80~0.85 m/min Inlet dust concentration: ≤800g /Nm3 Outlet dust concentration: ≤30mg/Nm3 |

| Fan | Total pressure: 7200 Pa; Airflow: 560000 m3/h Power: 1600 kW |

1.2 million tons/year slag powder production line

| Equipment | Parameters |

| LRMS56.3 vertical mill for slag | Capacity: ≥170 t/h, Specific surface area of product: ≥420m2/kg, Power: 5400 kW |

| Hot-blast stove | Heating capacity: 3.4×107 kcal/h |

| Dust collector | Airflow: 680000 m³/h, Filter area: 13592 m2 Filtration velocity: 0.80~0.85 m/min Inlet dust concentration: ≤800g /Nm3 Outlet dust concentration: ≤30mg/Nm3 |

| Fan | Total pressure: 7200 Pa; Airflow: 680000 m3/h Power: 1800 kW |

1.5 million tons/year slag powder production line

| Equipment | Parameters |

| LRMS63.3 vertical mill for slag | Capacity: ≥210 t/h, Specific surface area of product: ≥420m2/kg, Power: 6500 kW |

| Hot-blast stove | Heating capacity: 3.4×107 kcal/h |

| Dust collector | Airflow: 840000 m³/h, Filter area: 16310 m2 Filtration velocity: 0.80~0.85 m/min Inlet dust concentration: ≤800g /Nm3 Outlet dust concentration: ≤30mg/Nm3 |

| Fan | Total pressure: 7200 Pa; Airflow: 840000 m3/h Power: 2240 kW |

1.8 million tons/year slag powder production line

| Equipment | Parameters |

| LRMS66.4 vertical mill for slag | Capacity: ≥250 t/h, Specific surface area of product: ≥420m2/kg, Power: 8000 kW |

| Hot-blast stove | Heating capacity: 5.0×107 kcal/h |

| Dust collector | Airflow: 1000000 m³/h, Filter area: 19880 m2 Filtration velocity: 0.80~0.85 m/min Inlet dust concentration: ≤800g /Nm3 Outlet dust concentration: ≤30mg/Nm3 |

| Fan | Total pressure: 7200 Pa; Airflow: 1000000 m3/h Power: 2800 kW |

2 million tons/year slag powder production line

| Equipment | Parameters |

| LRMS70.4 vertical mill for slag | Capacity: ≥280 t/h, Specific surface area of product: ≥420 m2/kg, Power: 8500 kW |

| Hot-blast stove | Heating capacity: 5.6×107 kcal/h |

| Dust collector | Airflow: 1120000 m³/h, Filter area: 21400 m2 Filtration velocity: 0.80~0.85 m/min Inlet dust concentration: ≤800 g/Nm3 Outlet dust concentration: ≤30m g/Nm3 |

| Fan | Total pressure: 7200 Pa; Airflow: 1120000 m3/h Power: 3000 kW |

Related products

Send Message

Most Recent

More

Other Products

Videos