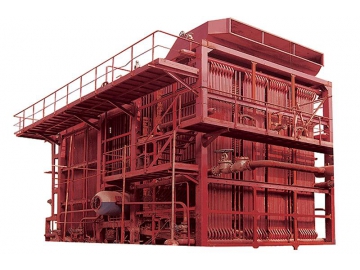

Horizontal Coal Fired Hot Water Boiler

Rated thermal power: 1.4-4.2 MW

Rated working pressure: 0.7-1.0Mpa

Fuel type: anthracite coal, meagre coal, lignitous coal, bituminous coal

The horizontal coal fired hot water boiler is an industrial package boiler. It is delivered in its complete form, and can be directly hoisted into the customer’s installation site for an easy installation. Using coal as its fuel, it is used for heat supply in cold areas, business and various industrial areas. Coal fired hot water boilers are used in a wide variety of locations, with normal pressure hot water boilers ideal for factories, hotels, hospitals, office buildings, schools and markets.

| Type | Rated thermal power( MW ) | Rated working pressure( Mpa ) | Water outlet temperature(℃) | Water inlet temperature(℃) | Circulating water flow( m3/h ) | Boiler volume( m3 ) | Design thermal efficiency (%) | Maximum dimension of shipping part ( m ) | Maximum weight of shipping part ( t ) | Boil installation dimension( m ) |

| 1.4 | 0.7/1.0 | 95 | 70 | 48.2 | 4.3 | > 77 | 7.4 × 2.6 × 3.5 | 28 | 7.4 × 3.4 × 4.6 | |

| 2.8 | 0.7/1.0 | 95/115 | 70 | 96/53 | 5.5 | > 78 | 7.5 × 2.6 × 3.5 | 30 | 7.5 × 3.4 × 4.6 | |

| 4.2 | 1 | 95/115 | 70 | 144/80 | 7.5 | > 78 | 8.5 × 3.2 × 3.65 | 57.5 | 8.5 × 4 × 4.8 |

The hot water boiler features complex processing links, and utilizes fine processing, which is an important factor in final product quality and safe usage by the customer.

1. Boiler material: seamless steel pipe

2. Welding process: Argon arc welding and radiographic testing

3. Bending shaping: The tube is shaped after the bending process in the pipe bending machine in order to ensure the coil outline dimension accuracy and ensure it meets GB/T17410 standards.

4. Water pressure testing: After shaping, the water pressure test for the tube is carried out before the boiler leaves the factory.

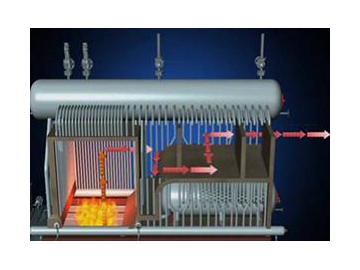

The industrial boiler is a natural circulation boiler that is divided into 2 parts. The upper area is the boiler heated surface, with the lower part consisting of the grate. The end of the boiler is equipped with an economizer and air-preheating system. The boiler also features a water circulation system, flue gas system, ash system and blowing system.

1. Boiler heated surface

The boiler heated surface consists of the steam drum, water drum, header, water wall and convection tube bundle. The water drum is also outfitted with a sewage device.

2. Grate

The boiler uses a chain grate with wind blowing from the bottom. There are 6 independent wind chambers in the grate, which can be adjusted based on user combustion conditions in order to save electricity.

3. Economizer

The economizer is placed on the tail end of the boiler, and is used to recover residual heat from the flue gas. When the temperature of the exhaust gas is too high, the economizer will reduce the temperature and save fuel.

4. Air per-heater

The air pre-heater can heat the air before it enters the boiler, and thus, improve the boiler’s combustion efficiency.

5. Water circulation system

Water source—pump—economizer—drum—downcomer-- water drum-- riser tube-- steam drum-- steam outlet

6. Ash system

After fuel burning, the resulting ash will be discharged using a slag extractor at the end of the grate. Ash that isn’t quickly discharged will fall into the front ash bucket with the chain grate running. This means users do need to regularly clean the grate.