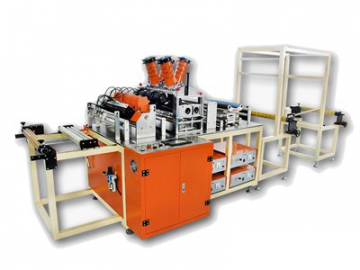

Ultrasonic Fabric Laminating Machine (Ultrasonic Bonding)

- Ultrasonic sonotrode: Imported magnesium aluminum

- Generator power : 20 KHz Jieda ultrasonic generator

- Max. Laminating width: 1600mm

- Operating speed: 1-25m/min

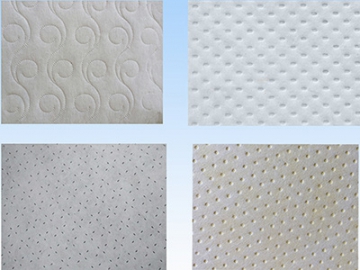

- Anvil roller: Length and patterns are customizable

- Anvil roller diameter: φ130mm-φ270mm

- Machine body: Welded steel structure

- Drive: PLC control

- Power supply: AC 220V 50Hz

- Total power: 13KW peak value

- Dimension: 9500*3100*1700 (for reference only)

- Weight: 1.8t (for reference only)

Ultrasonic non-woven laminating machine adopts high-frequency ultrasonic vibrations that are transmitted into the nonwoven materials under pressure. These vibrations cause the contact points to melt and bond, creating a solid joint between the two parts, typically cloth and cloth, cloth and chemical fiber, plastic film and plastic film, and other materials such as cotton, nonwoven fabric, sponge, etc.

This ultrasonic lamination machine can be custom manufactured with various patterns tailored to customer preferences, and laminating size is customizable according to the material roll size.

(The machine is offered in various configurations tailored to customer’s specific needs, available in single roller, dual rollers, three rollers and four rollers. And the vibrator can be driven by mechanical system, pneumatic cylinder or hydraulic system.)

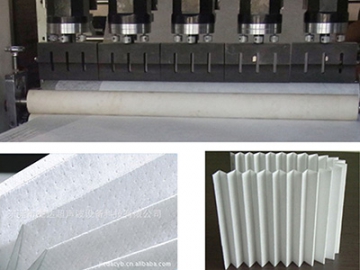

Materials: PVC tape, PE tape, EVA tape, PU latex leather, PP non-woven fabric, filter paper, nylon fabric, polyester fabric, pongee, Oxford cloth, polyester taffeta, TC fabric, and other materials containing chemical fiber;

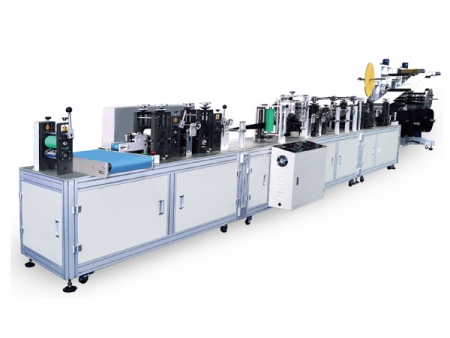

Industries: artificial leather, non-woven fabric, thermoplastic film, chemical plastic sheet, knitting, printing, clothing lining, shoemaking, baby and adult diaper, changing mat, sanitary pad, seat cushion, non-slip mat, bulletproof vest, bedding and automotive filter material;

-

Utilizing ultrasonic welding technology to replace conventional sewing method, eliminating the need for needles, thread or other consumables, providing strong bonding and superior embossing effect;

-

Ultrasonic system with specially manufactured steel roller enables edge to be sealed perfectly without fraying or unraveling;

-

Anvil roller is equipped with an adjusting unit that can quickly adjust the anvil roller level (anvil roller can be custom manufactured according to customer required patterns);

-

It can be designed with functions of finished product slitting and crosscutting, and double-station rotation winding according to customer’s requirements.

-

Tension control guarantees smooth rewinding, and the ultrasonic sonotrode is adjustable in horizontal motion;

Jieda ultrasonic system features stable power output, providing uniform welding while improving work efficiency. Automated running is carried out by microcomputer, easy to operate;

(The machine is offered in various configurations tailored to customer’s specific needs, available in single roller, dual rollers, three rollers and four rollers. And the vibrator can be driven by mechanical system, pneumatic cylinder or hydraulic system.)