Ball Mill

Introduction to Ball Mill

A Ball Mill is a rotating cylinder containing steel balls, which act as the grinding media. The material to be ground is put into the cylindrical barrel, which is rotated at a speed between 4 and 20 revolutions per minute, depending on the diameter of the mill. The larger the diameter of the cylindrical device, the slower the rotation speed. The rotation produces centrifugal forces which lift the balls to a given height causing them to fall back into the cylinder and onto the material to be ground. The product is mixed and crushed to powder by the grinding media (steel balls) as a result of the rotation. If the speed of the mill is too great, the cylinder will act as a centrifuge, causing the balls to stay on the perimeter of the mill instead of falling back. The point at which a ball mill acts as a centrifuge is called the "critical speed". The operating speed of ball mills is usually between 65% and 75% of the critical speed.

Application of Ball Mill

A ball mill is an efficient tool for grinding various kinds of materials into fine powder. They are generally used to grind material which is 1/4 inch or smaller, down to a particle size of 20 to 75 microns. For the ball mills to be efficient, the grinding has to be done in a closed system with the oversize material being continuously recirculated into the cylindrical barrel for reduction. Various classifiers such as screens, spiral classifiers, cyclones and air classifiers are used for classifying the discharge from ball mills.

Ball mills are largely used in the mining industry for the grinding and selection of material. They are also used in the construction industry (for building material), chemical industry, among others. The grinding may be carried out either through the dry process or the wet process. Ball mills can be classified into two main types namely, tabular type and flowing type, depending on the different forms of the discharged material.

Features of Ball Mill

1. The ball mill is an efficient grinding tool which is capable of grinding various types of material into fine powder.

2. The ball mill crushes and grinds many kinds of ores and rocks during mining. It is also used for mine selection.

3. Ball mills are widely used in the mining industry, construction industry and chemical industry.

4. Two grinding techniques that can be used are the dry-type grinding and the wet-type grinding.

5. The ball mill can either be of tabular type or flowing type depending on the form in which the material is discharged.

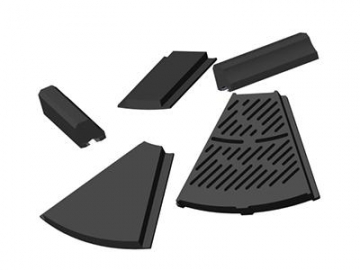

6. It contains a neoprene barrel that has grinding media in it. This is where the material to be ground is loaded into.

7. The barrel of the ball mill rotates at a specific speed causing the crashing of the material to powder form by the individual pieces of the grinding media. This may take several hours to complete. However, the longer the ball mill runs, the finer the powder will be.

8. The size of the ultimate particle largely depends on the hardness of the material to be ground and the amount of time used in the grinding process.

9. Our ball mills have been successfully used to grind glass, crush food products into powder, create custom varnishes, make ceramic glaze, and powder various chemicals among other uses.

Working Principle of Ball mill

A ball mill has rotating cylinder that is mounted horizontally and is controlled (driven) by an outer gearwheel. A quill shaft uniformly transfers the material to the grinding chamber. The chamber consists of different specifications of steel balls such as ladder linear and ripple linear.

Rotation of the horizontal cylinder creates centrifugal forces which elevates the balls to a certain height where they fall back, grinding the materials. The ground material is then discharged.

As a professional ball mill manufacturer in China, Henan Hongji Mine Machinery Co., Ltd. specializes in producing various kinds of mining machine which have passed ISO9001:2000 quality system certification and SGS certification. They are sold to Vietnam, Bengal, Myanmar, Laos, Peru, Philippines, Iran, India and other countries.

We can provide you with ball mill, spiral classifier, magnetic separator, flotation machine, mixer, drier, mining line and others.

Please contact us if you need any of them.

| Model | Rotational speed (r/min) | Ball load (t) | Feeding size (mm) | Output size (mm) | Capacity (t/h) | Power (kw) | Weight (t) |

| 36-38 | 1.5 | ≤20 | 0.075-0.89 | 0.65-2 | 18.5 | 4.6 | |

| 36 | 2.7 | ≤20 | 0.075-0.89 | 1.1-3.5 | 22 | 5.6 | |

| 36 | 3 | ≤25 | 0.075-0.6 | 1.5-4.8 | 30 | 12 | |

| 36 | 3.5 | ≤25 | 0.074-0.4 | 1.6-5 | 37 | 12.8 | |

| 32.4 | 5 | ≤25 | 0.074-0.4 | 1.6-5.8 | 55 | 13.8 | |

| 29.7 | 7.5 | ≤25 | 0.074-0.4 | 2-5 | 75 | 15.6 | |

| 27 | 11 | ≤25 | 0.074-0.4 | 3-6 | 90 | 21 | |

| 28 | 12 | ≤25 | 0.074-0.4 | 3.5-6 | 130 | 24.7 | |

| 25.4 | 11 | ≤25 | 0.074-0.4 | 4-10 | 130 | 28 | |

| 25.4 | 15 | ≤25 | 0.074-0.4 | 4.5-12 | 155 | 32 | |

| 24.1 | 21 | ≤25 | 0.074-0.4 | 6.5-15 | 210 | 34 | |

| 24.1 | 23 | ≤25 | 0.074-0.4 | 7.5-17 | 245 | 36 | |

| 23.7 | 15 | ≤25 | 0.074-0.4 | 6.5-36 | 210 | 34 | |

| 23.7 | 24 | ≤25 | 0.074-0.4 | 8-43 | 245 | 42 | |

| 23.7 | 26 | ≤25 | 0.074-0.4 | 8-48 | 280 | 50 | |

| 21.5 | 27 | ≤25 | 0.074-0.4 | 9-45 | 280 | 48.5 | |

| 21.7 | 35 | ≤25 | 0.074-0.4 | 14-26 | 370 | 52.8 | |

| 21.7 | 35 | ≤25 | 0.074-0.4 | 15-28 | 380 | 54 | |

| 21.7 | 35 | ≤25 | 0.074-0.4 | 15-30 | 380 | 56 | |

| 21 | 30 | ≤25 | 0.074-0.4 | 8.5-60 | 320 | 65 | |

| 20.7 | 40 | ≤25 | 0.074-0.4 | 12-80 | 400 | 94 | |

| 20.7 | 48 | ≤25 | 0.074-0.4 | 12-90 | 430 | 102 | |

| 18 | 65 | ≤25 | 0.074-0.4 | Depending on technological conditions | 800 | 137 |