Kelly Bar Classification and Structure

Locking kelly bar systems are designed for drilling hard materials, as well as when a crowd force application is needed. They come with drive rails designed with locking pockets on their length and the corresponding terminal joint locking guides.

The purpose is to interlock each telescopic element to an inner following element in order to apply maximum torque and crow force developed by the base rig. Due to this, the rotary table's inner drive is equipped with locking pockets.

When extracting the locking bar from the hole, a combination of lifting and rotating counterclockwise allows the telescopic element to unlock.

Locking bars typically come with 3, 4 and 5 telescopic elements.

Telescopic pipes steel quality: Q345B

Drive rails steel quality: German imported steel plate

Drive stub steel quality: Special forged steel

Drive stub dimensions: 200x 200, 150 x 150 or customized

Outer pipe available diameter: 254, 292, 298, 305, 343, 368, 378, 445

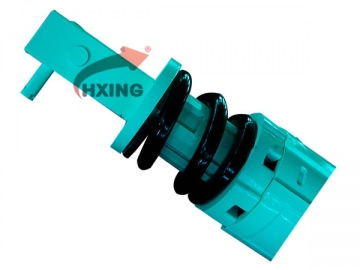

Upper shock absorber: Damping rubber ring

Lower shock absorber system: Damping rubber ring and damping spring

Number of telescopic elements: 3, 4, 5, 6, others on request

Friction kelly bars transfer the torque to the drilling tool. The telescopic elements are advanced using a “frictional contact” from each of the friction drive rails that run down the outside of each kelly bar. These drive rails are driven by the rotary table and the terminal joints of each successively larger diameter kelly bar. The terminal joint is a long piece on the inside and bottom of each kelly bars.

Friction kelly bars typically are available with 3, 4, 5, or 6 telescopic elements. They are primarily used for deep piles in medium hard soil conditions.

Telescopic pipes steel quality: Q345B

Drive rails steel quality: German imported steel plate

Drive stub steel quality: Special forged steel

Drive stub dimensions: 200 x 200 150 x 150 or customized

Outer pipe available diameter: 254, 292, 298, 305, 343, 368, 378, 445…

Upper shock absorber: Damping rubber ring

Lower shock absorber system: Damping rubber ring and damping spring

Telescopic elements number: 3, 4, 5, 6, others on request