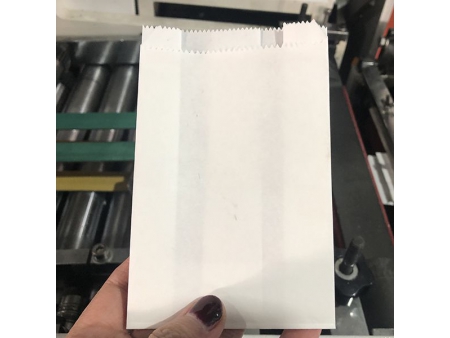

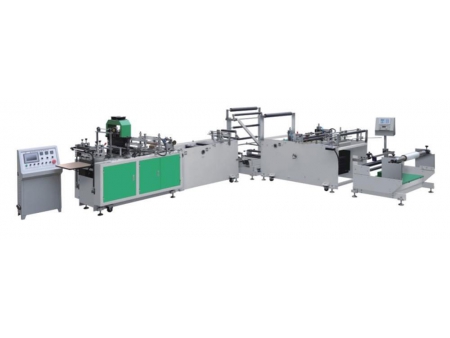

Pointed Bottom Bag Making Machine XKJD-400

General Type Roll-fed Paper Bag Making Machine for Paper Food Bag

Xinke XKJD-400 roll-fed paper bag making machine is a general type pointed bottom bag making machine that can manufacture various types of paper food bag in one process. The entire process of paper bag production involves paper roll unwinding, folding, tube formingcc, cutting, bottom folding, bottom gluing, and final bag collection. This paper bag machinery is suitable for a variety of blank or printed paper materials like kraft paper and coated paper in roll material. Controlled by servo motor, this model of flat and satchel paper bag machine allows for easy operation, high production efficiency and excellent performance. Furthermore, this paper bag machine can be equipped with 2-color or 4-color in-line printer for the production of printed flat and satchel paper bags with labels or patterns.

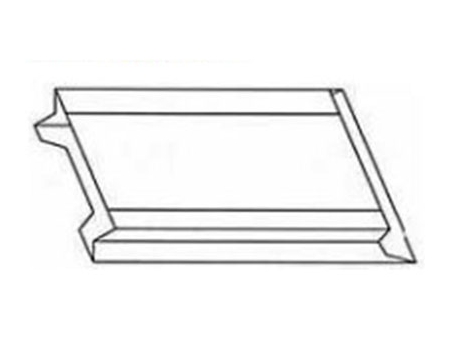

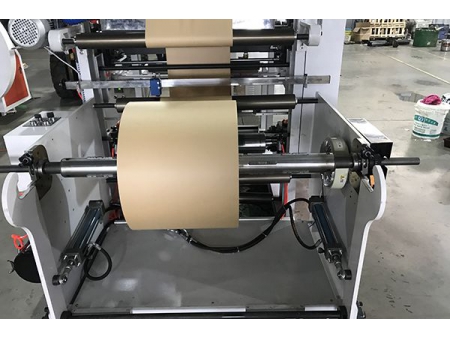

Paper roll unwinding

Paper roll unwinding Side gluing

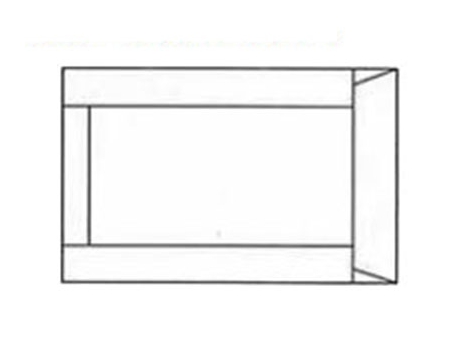

Side gluing Tube forming

Tube forming Separating

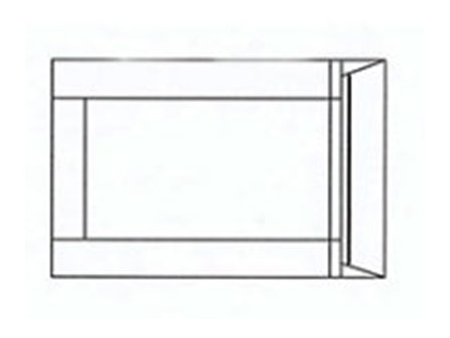

Separating Bottom gluing

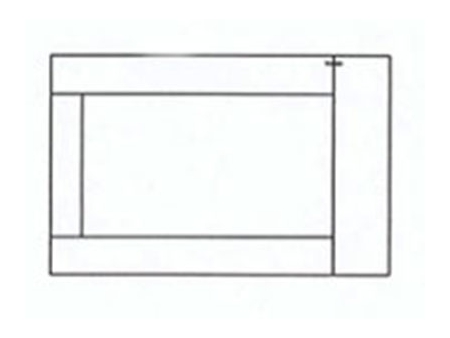

Bottom gluing Bottom folding

Bottom folding

- Model: XKJD-400

- Paper bag length: 120-420mm (L)

- Paper bag width: 80-240mm (W)

- Paper thickness: 40-80g/㎡

- Machine Speed: 60-400pcs/min

- Paper roll width: 260-720mm

- Side gusset: 20-100mm (2 gusset)

- Machine power: 6kw

- Machine weight: 1450kg

- Machine size: 4400×1700×1600mm

-

- HMI touch screen monitor displays the machine working status in real time, the length of paper bag can be simply adjusted via the HMI interface.

-

- Hydraulic roll lifting system of unwind unit enables paper roll to be easily loaded and unloaded, giving higher load capacity and less effort.

- Precise print mark detection system enables the automatic stopping of the machine when any errors are detected.

Touch screen

Touch screen  Paper cut to size

Paper cut to size - Side gusset forming

- Web guide sensor

- Photoelectric sensor (color sensor)

- Magnetic powder

- Paper bag discharging