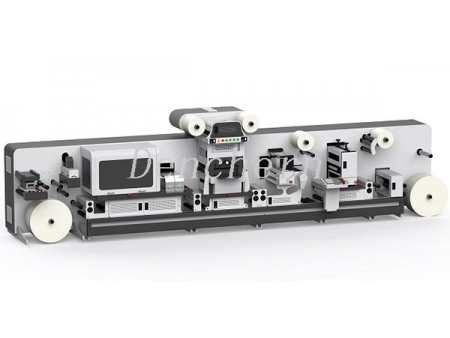

Die Cutting and Finishing Machine (Model DCFM-370 PRO Die Cutter and Finishing)

Request a Quote

The die cutting and finishing machine is designed with full rotary or intermittent flexo printing, die cutting, cold stamping, lamination, slitting, sheeting, etc., ensuring various jobs can be done in one process. This greatly enhances production efficiency.

Technical Specifications

| Model | DCFM-370 PRO |

| Max. Running Speed | 120times/min (full rotary mode), 300times/min (semi-rotary mode) |

| Max. Web Width | 370mm |

| Print Repeat | 200-450mm |

| Reprinting Precision | ± 0.15mm |

| Die Cut Repeat | 50-444.5mm |

| Die Cutting Precision | ± 0.15mm |

| Max. Unwinding Dia. | 800mm |

| Max. Rewind Dia. (Top Rewind Shaft) | 600mm |

| Max. Rewind Dia. (Bottom Rewind Shaft) | 800mm |

| Rewind Inner Core Size | 1inch-6inch (standard in 3inch) |

| Material Thickness | 20-300um |

| Air Source | 0.8Mpa |

Product Show

-

- Waste Matrix Removal System The waste matrix removal system features a sliding rewinding shaft, making waste rewinding convenient without adjusting the distance between waste rewinder and the stripping point. Designed with an independent motor drive, rewind shaft speed varies with machine speed.

-

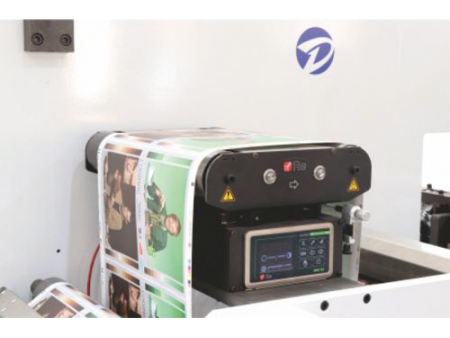

- Intermittent / Rotary Flexo Printing Unit Designed with a dual servo drive system, the printing unit features easy operation. It’s unnecessary to change print cylinder due to print length change, print cylinder positioning, and pre-registration. The water cooled UV dryer is adopted, and the IR dryer can be optional.

-

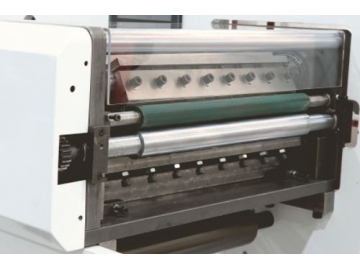

- Die Cutting Unit Driven by servo motor, the die cutting system comes with double servo motor traction, independent tracking system, intermittent and rotary interchangeable working mode.

-

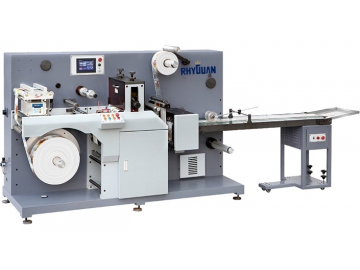

- Sheeter Unit It features dual servo motor drive, independent tracking system, digital control of cutting length, etc.

-

- Touch Screen The control panel is movable, and is designed with touch screen for easy operation.

-

- Web Guide System The web guide system from a well-known international brand provides high precision.

-

- Pressure Measurement System Two pressure gauges are designed on the top of two sides of the magnetic cylinder to ensure the pressure keeps constant during die cutting job. This also provides great convenience on checking the pressure data during running.

Related products

Send Message

Most Recent

More

Other Products

Videos