API 25-60 Ton High Speed Precision Metal Stamping Press

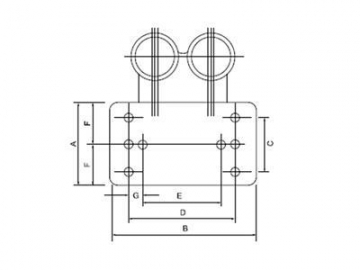

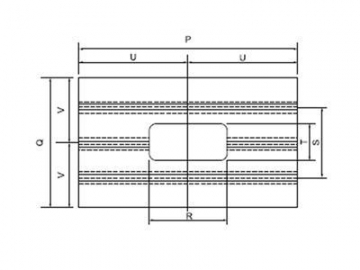

Slide plate

Slide plate Bolster plate

Bolster plate

- The API high speed precision metal stamping press is made from high strength, integrated casting which is engineered to ensure long-term precision.

- This stamping stress adopts a three-post slide guide structure, alloy steel bushing and forced lubrication to reduce the heat deformation and increase precision.

- The stamping press uses dynamic balancing system to control the stability of the bottom dead center (BDC) and reduce the vibration produced during high speed operation of the slide.

- A manual die height adjustment device is equipped with a die height indicator and oil press mold clamping device.

- A simple interface (electronic cam and rotary encoder) make it easy to operate.

- Liquid crystal display has complete operating functionality. The content of the engine base errors and alarm will automatic display on it.

- The clutch and brake adopt excellent single solenoid valve. It has high sensitivity, which can ensure the stamping press runs well and stops it precisely.

- The complete electric circuit can match automation equipment to improve production efficiency.

| Item | Unit | ||

| Type | A | B | |

| Capacity | Ton | 25 | |

| Stroke | mm | 30 | |

| Stroke per minute | S.P.M | 200-600 | 200-800 |

| Die height | mm | 210 | |

| Bolster | mm | 600x300x75 | |

| Area of slide | mm | 300x210 | |

| Slide adjustment | mm | 30 | |

| Blanking hole | mm | 300x100 | |

| Motor | kw | 3.7 | |

| Gross weight | kgs | 3000 | |

| Lubrication | Forceful Autom ation | ||

| Speed control | Inverter | ||

| Clutch & brake | Air & Friction | ||

| Auto top stop | Standard | ||

| Shock proof system | Optional | ||

| Item | Unit | ||

| Type | A | B | |

| Capacity | Ton | 45 | |

| Stroke | mm | 30 | |

| Stroke per minute | S.P.M | 200-500 | 200-700 |

| Die height | mm | 230 | |

| Bolster | mm | 700x420x100 | |

| Area of slide | mm | 460x320 | |

| Slide adjustment | mm | 30 | |

| Blanking hole | mm | 500x120 | |

| Motor | kw | 5.5 | |

| Gross weight | kgs | 4500 | |

| Lubrication | Forceful Autom ation | ||

| Speed control | Inverter | ||

| Clutch & brake | Air & Friction | ||

| Auto top stop | Standard | ||

| Shock proof system | Optional | ||

| Item | Unit | ||

| Type | A | B | |

| Capacity | Ton | 60 | |

| Stroke | mm | 30 | |

| Stroke per minute | S.P.M | 200-400 | 200-600 |

| Die height | mm | 275-305 | |

| Bolster | mm | 840x470x105 | |

| Area of slide | mm | 540x340 | |

| Slide adjustment | mm | 30 | |

| Blanking hole | mm | 560x100 | |

| Motor | kw | 7.5 | |

| Gross weight | kgs | 8000 | |

| Lubrication | Forceful Autom ation | ||

| Speed control | Inverter | ||

| Clutch & brake | Air & Friction | ||

| Auto top stop | Standard | ||

| Shock proof system | Optional | ||

Standard Configuration

1. Top stop

2. Manual slide adjusting device

3. Die height indicator

4. Inverter

5. Programmable logical controller (PLC)

6. Touch pad (preset counter, angle indicator include)

8. Encoder (electrical) 2 sets obligate

9. Operation cabinet at the front of frame

10. Air outlet

11. Sticking release device

12. Main motor (adjustable)

13. Hydraulic die locking device

14. Mechanical crank angle indicator

15. Circulated lubrication system

16. Tool box

17. User manual

18. Socket

19. Separate control cabinet

Optional Configuration

1. Anti-vibration

2. Feeder

3. Feeding material frame

4. Material lubrication device

5. Bottom dead center detector

6. Oil cooler

7. Die room light

8. Air ejector

Index

metal punching machine, power press, progressive die stamping, precision stamping