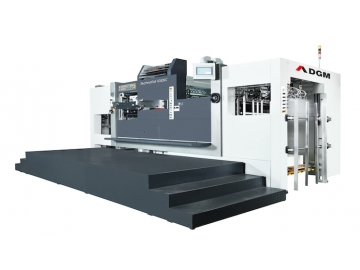

Characteristic - Gantry type high speed precision four post guider stamping press is made from high strength nodular cast iron. The metalworking machine tool delivers stable precision and reliability after eliminating the internal stress of the material.

- FEA was used to understand the structural strength and composite deformation, and guide the mechanism design.

- The three-section press structure provide high rigidity and were jointed to ensure the stability of the stamping press. The hydraulic power can reduce the deformation and vibration of the stamping machine.

- The dynamic balancing is used to reduce the noise and vibration when the stamping press is in high speed operation and lengthens the service life of the mold.

- The bent axle was made from copper alloy produced by China Molybdenum. After heat treatment, this bent axle was grinded using precise machine tools from Italy.

- The clutch and brake have high sensitivity which can locate precisely and deliver safe and reliable operation.

- The metal stamping press adopts forced circulation oil feeding, equips oil temperature regulating device and cooling control system. These special processes can restrain the thermal deformation of the machine base, ensuring the precision of the workpiece, lengthening the service life of the stamping press.

Technical Specifications | Item | Unit | APH-30 |

| Capacity | Ton | 30 |

| Stroke | mm | 30 | 25 | 20 |

| Strokes per minute | s.p.m | 200-900 | 200-1000 | 200-1200 |

| Bolster area | mm | 600x450 |

| Bolster hole | mm | 400x100 |

| slide | mm | 600x320 |

| Die height adjustment | mm | 225-275 |

| Adjusting motor | kw | 0.4 |

| Linear height | mm | 120 |

| Main motor | kw | 11 |

| Item | Unit | APH-45 |

| Capacity | Ton | 45 |

| Stroke | mm | 30 | 25 | 20 |

| Strokes per minute | s.p.m | 200-800 | 200-900 | 200-1100 |

| Bolster area | mm | 750x550 |

| Bolster hole | mm | 550x125 |

| slide | mm | 750x380 |

| Die height adjustment | mm | 240-290 |

| Adjusting motor | kw | 0.4 |

| Linear height | mm | 135 |

| Main motor | kw | 15 |

| Item | Unit | APH-60 |

| Capacity | Ton | 60 |

| Stroke | mm | 30 | 25 | 20 |

| Strokes per minute | s.p.m | 200-800 | 200-900 | 200-1000 |

| Bolster area | mm | 950x650 |

| Bolster hole | mm | 700x125 |

| slide | mm | 950x420 |

| Die height adjustment | mm | 300-350 |

| Adjusting motor | kw | 0.4 |

| Linear height | mm | 160 |

| Main motor | kw | 19 |

| Item | Unit | APH-80 |

| Capacity | Ton | 80 |

| Stroke | mm | 30 | 25 |

| Strokes per minute | s.p.m | 200-700 | 200-800 |

| Bolster area | mm | 1100x750 |

| Bolster hole | mm | 800x150 |

| slide | mm | 1100x500 |

| Die height adjustment | mm | 330-380 |

| Adjusting motor | kw | 0.75 |

| Linear height | mm | 175 |

| Main motor | kw | 22 |

| Item | Unit | APH-125 |

| Capacity | Ton | 125 |

| Stroke | mm | 30 |

| Strokes per minute | s.p.m | 150-700 |

| Bolster area | mm | 1200x850 |

| Bolster hole | mm | 1000x200 |

| slide | mm | 1200x600 |

| Die height adjustment | mm | 360-410 |

| Adjusting motor | kw | 0.75 |

| Linear height | mm | 195 |

| Main motor | kw | 37 |

| Item | Unit | APH-200 |

| Capacity | Ton | 200 |

| Stroke | mm | 30 |

| Strokes per minute | s.p.m | 150-600 |

| Bolster area | mm | 1700x950 |

| Bolster hole | mm | 1300x250 |

| slide | mm | 1700x700 |

| Die height adjustment | mm | 370-420 |

| Adjusting motor | kw | 1.5 |

| Linear height | mm | 200 |

| Main motor | kw | 45 |

| Item | Unit | APH-300 |

| Capacity | Ton | 300 |

| Stroke | mm | 30 |

| Strokes per minute | s.p.m | 150-400 |

| Bolster area | mm | 2000x1000 |

| Bolster hole | mm | 1520x330 |

| slide | mm | 2000x900 |

| Die height adjustment | mm | 400-450 |

| Adjusting motor | kw | 2.2 |

| Linear height | mm | 210 |

| Main motor | kw | 50 |

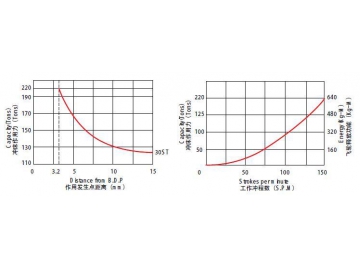

Capacity curveStandard Configuration

1. Electric die height adjusting equipment

2. Digital die height indicator (0.01mm)

3. Micre inching function

4. 30 sets memory for die setting data

5. Lot "A", "B", "C", contorl for auto-stacking

6. 2 sets of mis-feed detecting receptcle

7. Single action and continuous action can locate 0º and 90º

8. Two way rotation main motor control

9. Hydraulic clamping unit for die height adjusting

10.Lubricant cooling device

11.Separated clutch/brake

12.Independent electric control box

13.Tool box

14.Work light

Optional Configuration

1. Die height detector

2. Hydraulic die clamping device

3. Hydraulic die lifter & die arms

4. Hi-speed gear change feeder

5. Double head un-coiler

6. Leveler & "S" loop control

7. Anti-vibration mounts

8. F-3SC stamping controller

9. Inverter control for main motor

10. Two side sound proof safety door

Customer Case about metal stamping press Index

metal punching machine, power press, progressive stamping