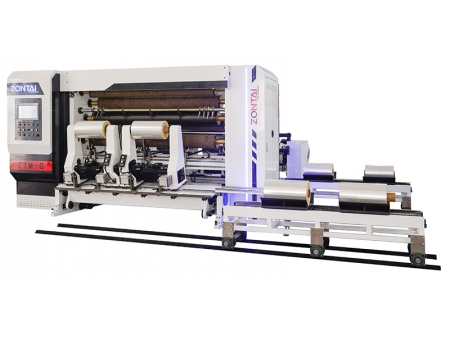

Vertical Slitting Rewinding Machine, ZTM-DT

Request a Quote

Suitable for handling paper, kraft paper, adhesive paper, films, foils, labels and laminates

The ZTM-DT vertical slitting rewinding machine is built with structure of unwind and rewind at the same side. It works at high speeds of up to 400m/min to cut a large roll of various materials to different widths, and then rewinds the material to form several narrower rolls. These vertical slitter rewinders are ideal for converting PET, OPP, CPP, PE, PS, PVC, cellophane, anti-counterfeit labels, optical films, foils, laminates, coated paper and printed substrates.

Specifications

Details

| Model | | |

| Web width | 1300mm | 1600mm |

| Diameter of unwind | Ø800mm | Ø800mm |

| Diameter of rewind | Ø450mm | Ø450mm |

| Paper core size for unwind | 3″and 6″ | 3″and 6″ |

| Paper core size for rewind | 3″ | 3″ |

| Slitting speed | 10-400m/min (for different materials, speed will be different) | 10-400m/min (for different materials, speed will be different) |

| Substrate thickness | 10-100micron | 10-100micron |

| Tolerance of EPC | ≤0.1mm | ≤0.1mm |

| Min. slitting width | 50mm | 50mm |

| Total power | 12kW | 15kW |

| Machine weight | 3600kg | 3800kg |

| Overall dimensions | 1650mm×3800mm×1830mm | 1650mm×4300mm×1830mm |

- Pneumatic differential friction shaft (3 inches)

- EPC device

- Shaftless unwind unit

- PLC control panel

- Air shaft for rewinder

- Razor blades for film slitting

- Unwind and rewind in one side

- Automatic finished roll pushing device (optional)

- Finished rolls holding frame

- The entire slitter rewinder machine is controlled by PLC system with user-friendly touch screen HMI, and the vertical structure of unwind and rewind at the same side makes the operation easier.

- Unwind station uses magnetic powder brake from Taiwan brand, the web tension is automatically controlled by load cell and PLC system.

- One servo motor drives the traction roller, maintaining linear velocity at a steady state while enabling the unwinding tension to be efficiently isolated from the rewinding tension.

- Rewind station adopts two servo motors, and rewind tension control can be achieved by PLC automatic compensation of roll diameter change.

- The slitting rewinding machine is equipped with robot arm for automatic pushing finished rolls.

- Unwind station has a hydraulic lifting mechanism for automatic loading of mother rolls, thus greatly saving labor intensity and reducing working time.

- EPC & LPC web guide systems ensure accurate slitting of materials, with smooth cut edge.

Related products

Send Message

Most Recent

More

Other Products

Videos