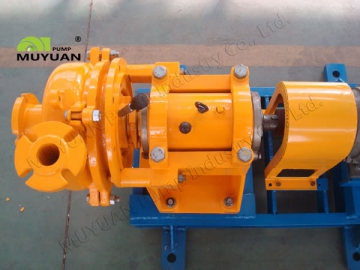

Heavy Duty Slurry Pump

Features

1. The MYU series heavy duty slurry pump is a single-suction pump that allows slurries to enter inside the pumping chamber from only one suction side. Available with one impeller, the single-stage pump is a horizontal cantilever unit.

2. This MYU series pump offers choices of pump casings. The pump with its diameter less than 6" comes with an integrated one-piece case while larger pumps are provided with axially-split cases. The wet-end parts of the pump are made of corrosion-resistant high-chrome.

3. High-efficiency vanes enable more than 10% improvement in pumping efficiency over the MA series.

4. Types of shaft seal: packing gland seal, expeller seal, and mechanical seal

5. Multiple MYU series cantilever slurry pumps can be installed operating in series.

6. The discharge outlet has 8 positions at 45 degree intervals that can be selected to meet the installation and application requirements.

Advantages

1. The physical layout of our horizontal heavy-duty slurry pumps simplifies maintenance operations and ensures long service life. It also suits the pumps for heavy-duty tasks.

2. This small-diameter pump features a single one-piece case, which reduces weight and production cost. Larger diameter pumps come with axially split cases made from ductile cast iron to withstand pressure. Internal pipe linings are constructed of wear-resistant materials, allowing for easy replacement and repair.

3. The slurry pump body is fixed to the mounting base by several bolts. Users can adjust the clearance between impeller and suction liner easily from underneath a bearing pedestal.

4. Packing gland seal, mechanical seal and expeller seal are available to prevent slurry leakage during pumping operation.

Hydraulic Modeling

Wet-end components are cast of hard metal or polyurethane. They are able to maintain good hydraulic performance even when the pump is subject to severe wear. This helps the slurry pump achieve optimal levels of pumping efficiency for an extended period. Various impeller designs are available to suit the pump for various pumping applications. Pumping vanes are designed by means of hydraulic modeling.

Shaft Seals

Packing Seal

As one of the most commonly used seals for rotating shafts, the gland seal can come with low-flush or full flush arrangement which uses flushing water to prevent media from escaping the pump housing. This kind of seal is suitable for use in almost all pumping applications. In situations where corrosive solids or high temperature might be encountered, Teflon or aramid fiber is used as packing material for the gland. To further increase the shaft's resistance to abrasion, a ceramic coated shaft sleeve would be used.

Centrifugal Seal-Expeller

The combination of impeller and expeller creates the pressure needed to seal against leakage. Together with the gland seal or lip seal which is used as the shut-down seal, this type of seal can handle sealing requirements for applications where full-flush gland seal is impractical due to lack of water on the site, or sealing water is allowed to enter inside the pumping chamber to dilute the slurry.

Mechanical Seal

Advances in sealing technology allows us to create a mechanical seal that ensures zero leakage. Cartridge type mechanical seal facilitates installation and replacement. Other types of mechanical seal are among options to suit the heavy duty slurry pump for various pumping applications. We also utilize special ceramic and alloys of high strength and hardness on parts that are subjected to friction. Unique design of and seamless fit between the mechanical seal and seal chamber provides excellent resistance to abrasion and shock that ensures its effectiveness under the toughest conditions.

Transmissions

Cartridge Type Oil-Lubricated Bearing Assembly

Spacious cartridge design allows for the installation of a large-diameter rotating shaft. Built specially to handle heavy-duty tasks, the metric size bearing is lubricated by thin oil. Users can install several bearings operating in series. Compact design and high reliability are 2 major benefits of this bearing for its end users.

Installation Types

DC Type: The output shaft of a motor is directly connected to the input shaft of a pump via a pump coupler. This type of connection is suitable for applications where the speed of the slurry pump is the same as that of the motor.

CV Type: The pump is driven by a belt connected to the crankshaft of the engine. This way of connection allows for saving space, easy installation, and fast adjustment of pumping speed. The motor is fixed to the motor support frame which is located on the bearing pedestal above the pump.

ZV Type: Another type of belt drive that allows easy adjustment of pumping speed. The motor is directly fixed to the bearing pedestal. This way of installation is suitable for motors with larger horsepower than is possible with CV type of installation. Due to the installation of motor onto the bearing pedestal, this method helps save installation space.

CR Type: This type of belt drive makes it easier to adjust pumping speed. The installation allows both the motor and slurry pump to be fixed to the ground. The motor is installed to the side of the pump. This installation method is suitable for large-power motors.

Applications

Feeding slurries to hydrocyclones or pressure filters in mining industry, mineral recycling, mine dewatering, coal dressing, metallurgy.

Parameters

Technical Parameters

Size: 2"- 6"(50 - 150mm)

Flow rate: 20 - 170m3/h

Total head: 5 - 75m

Components

| Parts | Material | Material Code | Description | Hardness | Performance | Applications |

| Wet-end Parts, Expeller, Expeller Ring, Stuffing Box | Metal | M05 | 27% High-Chrome Cast Iron | HRC≥58 | Erosion resistance is marginally lower than M07 and has corrosion resistance. | Used for high wear applications with a slurry pH between 5 and 12. |

| M07 | 15% High-Chrome Cast Iron | HRC≥59 | Excellent erosion resistance and has higher wear resistance than M05 | Mining pumps ideal for high impact and high pressure applications, such as pumping slurries with sharp, hard, and coarse solids at high flow rate. | ||

| M12 | 30% High-Chrome Cast Iron | HRC≥65 | With abrasion resistance better than M05 and M07. | Suitable for highly abrasive pumping applications. | ||

| M33 | 35% Ultra High Chrome Cast Iron | HRC=35 | This material has erosive and corrosive resistance in low pH applications. Its abrasion resistance is higher than that of M49. | The material can be used to transport oxygenated slurries with pH of not less than 1 such as phosphor-plaster, nitric acid, vitriol, phosphate etc | ||

| M49 | 29% High Chrome Cast Iron | HRC=43 | With a certain degree of scour resistance and good corrosion resistance under low pH conditions. Its abrasion resistance is higher than M05. | Particularly suitable for use in flue gas desulphurization as well as mild acid applications with pH value no less than 4. | ||

| Frame Plate, Cover Plate, Bearing Housing, Slurry Pump Base | Metal | Ductile Cast Iron | ||||

| Shaft | Metal | 1045 | ||||

| Shaft Sleeve, Shaft Spacer, Lantern Ring, Neck Ring, Lantern Restrictor | Metal | Stainless Steel |