ZL Series Light Duty Sludge and Slurry Pump

ZL(R) series light duty sludge and slurry pump are single-stage, single-suction, cantilever, double casing and horizontal centrifugal slurry pump which apply to operating conditions of large flow, low concentration and lower head. When the speed is low, this pump can transmit slurry of strong abrasion and high density. Compared with WX type slurry pump of equivalent diameter, this type is of small size, light weight and high cost performance and has been widely used in metallurgy, electric power, chemical industry, mining, papermaking, building materials and other industries.

Application| Caliber | 20mm~650mm |

| Maximum flow | 10260m³/h |

| Maximum head | 63m |

| Rotation | 200-3000r/min |

| Power | 7.5-1200kw |

For details see clear water performance table.

ZL clear water performance table| Type | Maximum motor power KW | Material | Clear water performance | ||||||

| Liner bushing | Impeller | Capacity Q | Head | Speed | Efficiency | NPSH | |||

| (m³/h) | (l/s) | (m) | (r/min) | η% | (m) | ||||

| 7.5 | M | M | 2.34-10.8 | 0.65-3 | 6-37 | 1400-3000 | 39 | 3-5 | |

| RU | RU | 2.69-9 | 0.6-2.5 | 7-32 | 1600-3000 | 33 | |||

| 15 | M | M | 16.2-76 | 4.5-20 | 9-44 | 1400-2800 | 62 | 3-5 | |

| RU | RU | 12.6-60 | 3.5-17.6 | 6-38 | 1200-2600 | 48 | |||

| 30 | M | M | 18-151 | 5-42 | 4-45 | 900-2400 | 57 | 3-6 | |

| RU | RU | 25-144 | 7-40 | 9-43 | 1000-2200 | 60 | 3-5 | ||

| 60 | M | M | 50-252 | 14-70 | 7-46 | 800-1800 | 60 | 2-3.5 | |

| RU | RU | 61-252 | 17-70 | 8-38 | 800-1600 | 65 | 2-5 | ||

| 120 | M | M | 115-468 | 32-135 | 12-51.5 | 800-1500 | 65 | 2-6 | |

| RU | RU | 137-486 | 38-135 | 10-36.5 | 800-1300 | 2.5-5.5 | |||

| 120 | M | M | 446-1325 | 124-368 | 14-63 | 600-110 | 73 | 3-14 | |

| RU | RU | 277-1088 | 27-322 | 11-43 | 500-900 | 79 | 3-10 | ||

| 260 | M | M | 468-1386 | 130-385 | 9-47 | 500-1000 | 73 | 3-10 | |

| RU | RU | 522-1278 | 140-355 | 10-39 | 500-900 | 73 | 5-10 | ||

| 560 | M | M | 468-2538 | 130-705 | 8-60 | 400-950 | 79 | 2-10 | |

| RU | RU | 432-1900 | 120-528 | 7-41 | 400-800 | 81 | 3-8 | ||

| 560 | M | M | 650-2800 | 180-780 | 10-59 | 400-840 | 81 | 3-10 | |

| RU | RU | 720-2811 | 200-790 | 10-41 | 400-700 | 86 | 3-7.5 | ||

| 560 | M | M | 720-3312 | 200-920 | 7-51 | 300-700 | 80 | 2-10 | |

| RU | RU | 756-3312 | 210-920 | 7-37.5 | 300-600 | 85 | 2-8 | ||

| 560 | M | M | 1008-4356 | 280-1210 | 9-48 | 300-600 | 80 | 2-9 | |

| RU | RU | 1080-4356 | 300-1210 | 9-40 | 300-550 | 87 | 3-10 | ||

| 1200 | M | M | 1440-5580 | 400-1550 | 8-51 | 250-550 | 86 | 3-10 | |

| RU | RU | 1152-5112 | 320-1420 | 8-42 | 250-500 | 87 | 3-10 | ||

| 1200 | M | M | 1980-7920 | 560-2200 | 10-50 | 250-475 | 86 | 4-10 | |

| RU | RU | 2160-6660 | 600-1850 | 13-43 | 250-425 | 88 | 3-10 | ||

| 1200 | M | M | 3600-10260 | 1000-2850 | 10-57 | 200-425 | 86 | 4-10 | |

| RU | RU | 2520-9108 | 700-2530 | 10-39 | 200-350 | 86 | 2-8 | ||

Structural features

1. This pump is applicable to high duty and severe operating conditions for having large diameter and short cantilever to ensure the rigidity of the shaft.

2. The hardened stainless sleeve and the shaft are equipped through clearance fit, coupled with O-ring on the two ends, thus the shaft is of wear-resisting and anti-corrosion.

3. Either the front or back cover board of the impeller is equipped with auxiliary blade, which can reduce the return flow and the seal pressure. Other methods like a wider-runner and blade concave are adopted to enhance overcurrent ability and anti-abrasion ability for extending the service life.

4. The ability of withstanding high pressure of the pump casing and cover is ensured by using ductile iron material and strengthening rib.

5. The overcurrent components adopt various high Cr anti-abrasive alloys or different rubber and are of anti-abrasive, anti-corrosion, impact resistance, scouring resistance and other features. Moreover, the metal overcurrent components and the rubber ones can be used interchangeably or in a mixer way to satisfy the requirement of different operating conditions.

6. Seal types like packing seal, auxiliary impeller seal, and mechanical seal are available for shaft seal to satisfy different seal requirement.

7. You can choose to install the output position of the pump by eight different angles (with an interval of 45 degrees).

8. Oil lubrication and grease lubrication are provided to the bearing assemblies. The oil lubrication components is able to lower the operation temperature effectively to reduce the trouble caused by too high bearing temperature. The grease lubrication components have features of simple structure, reliable operation, and easy installing, commissioning and maintenance.

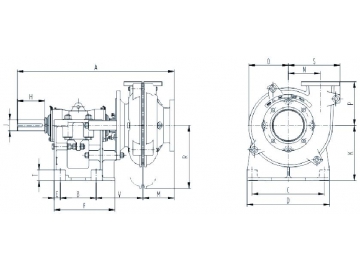

Outline drawing

| Pump model | A | B | C | D | E | F | H | J | K | M | N | S | T | V | Q | R | P | Suction flange | Discharge flange | The anchor hole | Weight(Kg) | ||||||||

| O.D | I.D | P.C.D | HOLES | O.D | I.D | P.C.D | HOLES | Metal | Rubber | ||||||||||||||||||||

| 461 | 159 | 241 | 286 | 25 | 210 | 57 | 20 | 145 | 90 | 86 | 144 | 28 | 89 | 128 | 124 | 128 | 114 | 25 | 83 | 4-Ф14 | 102 | 20 | 73 | 4-Ф14 | 4-φ18 | 32 | 28 | ||

| 624 | 143 | 254 | 295 | 24 | 248 | 80 | 28 | 197 | 136 | 114 | 197 | 38 | 191 | 155 | 154 | 163 | 184 | 75 | 146 | 4-Ф19 | 165 | 50 | 127 | 4-Ф19 | 4-φ14 | 58 | 46 | ||

| 813 | 175 | 356 | 406 | 32 | 311 | 120 | 42 | 254 | 163 | 146 | 248 | 48 | 253 | 191 | 198 | 204 | 229 | 100 | 191 | 4-Ф19 | 203 | 75 | 165 | 4-Ф19 | 4-φ19 | 163 | 144 | ||

| 950 | 213 | 432 | 492 | 38 | 364 | 163 | 65 | 330 | 187 | 190 | 308 | 64 | 280 | 236 | 249 | 262 | 305 | 150 | 260 | 4-Ф22 | 229 | 100 | 191 | 4-Ф22 | 4-φ22 | 343 | 309 | ||

| 1218 | 257 | 546 | 622 | 54 | 448 | 220 | 80 | 457 | 237 | 248 | 403 | 76 | 376 | 303 | 324 | 324 | 368 | 200 | 324 | 8-Ф19 | 305 | 150 | 260 | 8-Ф19 | 4-φ29 | 718 | 696 | ||

| 1343 | 257 | 546 | 622 | 54 | 448 | 220 | 80 | 457 | 306 | 381 | 613 | 76 | 413 | 451 | 540 | 401 | 445 | 250 | 394 | 8-Ф22 | 382 | 200 | 337 | 8-Ф22 | 4-φ29 | 1625 | 1164 | ||

| 1549 | 349 | 762 | 857 | 95 | 636 | 280 | 100 | 610 | 324 | 438 | 696 | 98 | 451 | 476 | 603 | 470 | 552 | 305 | 495 | 8-Ф32 | 483 | 254 | 425 | 8-Ф32 | 4-φ35 | 1998 | 1340 | ||

| 1720 | 640 | 760 | 920 | 70 | 780 | 280 | 120 | 450 | 300 | 475 | 740 | 90 | 415 | 599 | 634 | 570 | 560 | 350 | 500 | 12-Ф26 | 530 | 300 | 470 | 12-Ф26 | 4-φ35 | 2270 | 1802 | ||

| 1776 | 640 | 760 | 920 | 70 | 780 | 280 | 120 | 450 | 340 | 530 | 825 | 90 | 425 | 643 | 691 | 620 | 640 | 400 | 580 | 12-Ф26 | 590 | 350 | 530 | 12-Ф26 | 4-φ35 | 3630 | 2823 | ||

| 1840 | 620 | 900 | 1150 | 80 | 780 | 280 | 120 | 650 | 375 | 600 | 942 | 125 | 480 | 747 | 809 | 740 | 720 | 450 | 650 | 12-Ф33 | 685 | 400 | 615 | 12-Ф33 | 4-φ48 | 4210 | 3212 | ||

| 1875 | 620 | 900 | 1150 | 80 | 780 | 280 | 120 | 650 | 400 | 660 | 1040 | 125 | 500 | 814 | 872 | 800 | 770 | 500 | 700 | 12-Ф33 | 740 | 450 | 670 | 12-Ф33 | 4-φ48 | 5596 | 4211 | ||

| 2291 | 880 | 900 | 1150 | 80 | 1040 | 350 | 150 | 650 | 437 | 780 | 1251 | 125 | 492 | 1013 | 1112 | 975 | 875 | 550 | 780 | 12-Ф39 | 850 | 500 | 750 | 12-Ф39 | 4-φ48 | 8172 | 6356 | ||

| 2400 | 860 | 1200 | 1460 | 95 | 1050 | 350 | 150 | 900 | 625 | 860 | 1313 | 150 | 625 | 1055 | 1142 | 975 | 975 | 650 | 880 | 12-Ф39 | 900 | 550 | 800 | 12-Ф39 | 4-φ79 | 10900 | 8263 | ||

| 2517 | 860 | 1200 | 1460 | 95 | 1050 | 350 | 150 | 900 | 641 | 1020 | 1553 | 150 | 641 | 1248 | 1360 | 1175 | 1175 | 800 | 1092 | 12-Ф55 | 1050 | 650 | 950 | 12-Ф45 | 4-φ79 | 18780 | 13915 | ||

All dimensions are in millimeters (mm)