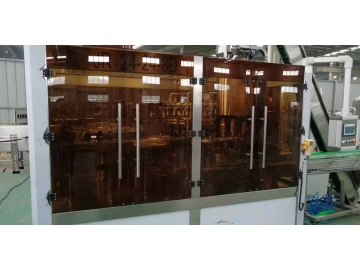

3-in-1 Automatic Water Bottling Machine (2-10L)

Request a Quote

Monoblock Rinsing, Filling and Capping Machine for Drinking Water and Mineral Water

Basic Information

- Bottle type: PET bottles

- Cap type: plastic screw caps

- Bottle volume: 2-10L

- Washing method: adopting newly developed mechanical valve that precisely controls the rinsing fluid, without leakage of water, the rotary rinser is configured with large-volume bottle body protection unit to ensure reliable and stable rotation of large bottles

- Filling method: gravity filling system ensures stable filling process

- Capping method: magnetic clutch capping head is used for closing of plastic screw caps and sport closures, the torque is easily adjustable for reliable cap closing quality

Specifications

| Model | Production output (5L PET bottle) | Overall dimensions (L×W×H) | Power | Weight |

JR8-8-4TD | 1000 b/h | 3200×2250×2300mm | 3 kW | 4000 kg |

JR12-12-4TD | 1500 b/h | 3600×2950×2300mm | 5.5 kW | 5500 kg |

JR16-16-5TD | 2000 b/h | 4000×3300×2300mm | 5.5 kW | 6500 kg |

JR20-20-5TD | 2800 b/h | 4200×3300×2300mm | 5.5 kW | 8000 kg |

JR25-25-6TD | 3800 b/h | 4200×3300×2300mm | 5.5 kW | 9500 kg |

Features

- Particularly used for filling of mineral water and purified water into large-volume PET bottles, with rinsing, filling and capping functions in one machine;

- Adopting newly developed air conveyor for bottle in-feeding, providing fast conveying without damage;

- Empty bottles are transferred with bottle neck clamping and bottle body protecting method, while filled bottles are transferred by the same method coupling with means of bottle bottom supporting;

- Only few parts need to be replaced when changing bottle shape, these parts are easily replaceable for quick and easy bottle size changing;

- Equipped with PLC control and frequency converter to guarantee highly automatic production and smooth operation, and the touch screen panel enables all settings to be easily accessible;

Details

-

- Washing Station

-

- Rotary bottle rinser is used in this automatic liquid filling machine, it enables the inside of empty glass or plastic containers to be thoroughly cleaned prior to filling process.

- PET bottles are fed into the monoblock machine by means of indexing star wheel and grasped by bottle neck gripper that turns bottles upside-down centrally above the spraying nozzle to rinse the inside of bottle with sterile water. Following rinsing, the bottle is then allowed to drip, automatically re-inverted and transferred to the filling turret through the outfeed star wheel.

- All parts in contact with rinsing fluid and exterior wall cladding are made from high quality stainless steel.

- The stainless steel gripper is featured by simple structure and easy adjustment, and the small contact surface minimizes the secondary contamination of bottle neck.

-

- Filling Station

-

- After entering the gravity filler, bottles are retained by neck supporting carrier plates and raised by cam mechanism to actuate the opening of filling valves which allow bottles to be filled. When the filling process is completed, bottles are lowered to disengage with filling valves and transferred into the capper by neck handling star wheel.

- Filling volume can be slightly adjusted, the liquid level of filled bottles is constant.

- Gear transmission mechanism is used to provide high efficiency, low noise level, long service life, and easy maintenance.

- Speed regulation is achieved by frequency converter.

-

- Capping Station

-

- Bottle caps discharged from cap sorter are placed in the right position and screwed on filled bottles, and then bottles are transferred to the downstream process via conveyor.

- The pick & place system performs cap closing by electromagnetic capping heads, avoiding the collision between bottles during the capping process.

- The capper structure is constructed with 304/316 stainless steel.

- The capping process will stop automatically when there is no bottle.

- High capping efficiency can be guaranteed, the failure rate is less than 0.2%.

Related products

Send Message

Most Recent

More

Other Products

Videos