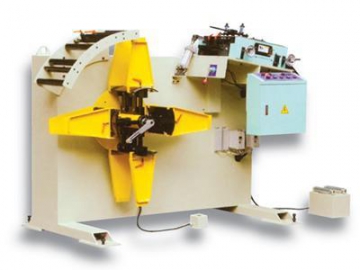

APD 80-260 Ton Precision Metal Stamping Press

Request a Quote

- APD 80-260 Ton precision metal stamping press was developed and manufactured with a strong steel structure and welded using high quality steel plate. The stamping machine tool features stable precision and reliability after eliminating the internal stress of the material.

- The transmission center and metalworking machine tool center are located in the same spot, so that the stamping press can optimize precision and stability.

- A symmetrical balancer is used to ensure operational stability.

- The precision of die height adjustment is as high as 0.1 mm, so the stamping press can be operated safely, conveniently and reliably.

- The parts, like bent axle, gear systems, connecting rod, etc., have high integrality and abrasive resistance after hard-anodized and grinding process.

- Sensitive and reliable clutch/brake, excellent double solenoid valve and overload protector are used to ensure the precision and safety of the start and stopping of the slide.

- This straight side frame press features an integrative rack, which makes it suitable for processing precise progressive dies.

- The stamping press avoids the defect of C frame presses, reducing maintenance costs during the metalworking process.

- The stamping machine tool has strong steel structure, and the slide way is located in the center line of the joint. These characteristics mean it has long-term dynamic stability precision and long mold service life.

- The bottom area of the puncher pin is 15-25% larger than that of model C stamping presses. This is beneficial for increasing the number of die engineering and additional values of the metalworking process.

- It features a high torque wet clutch, delivering long service life and low maintenance costs.

- The multifunctional electronic control system results in high operational safety.

- A series of automation equipment provides convenience in operation.

| Name | Model | ||

| Type | Type V | Type H | |

| Capacity | Ton | 80 | |

| Rated tonnage point | mm | 4 | 2 |

| Stroke | mm | 150 | 70 |

| Die height | mm | 340 | 380 |

| Stroke per minute | s.p.m | 35-80 | 80-120 |

| Slide adjustment | mm | 80 | |

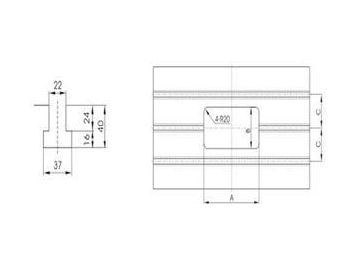

| Slide area | mm | 560×420×70 | |

| Bolster area | mm | 760×550×90 | |

| Main motor | kw.p | 7.5 | |

| Slide adjust device | HP | Electrical driving | |

| Air pressure | kg/cm2 | 6 | |

| Dimension (length×width×height) Presses dimension | mm | 1300×1890×3000 | |

| Presses weight | Ton | 7.8 | |

| Presses precision | GB(JIS) 1 class | ||

| Die cushion capacity | Ton | 3.6 | |

| Stroke of cushion die | mm | 70 | |

| Die cushion effective area | mm2 | 450×310 | |

| Name | Model | ||

| Type | Type V | Type H | |

| Capacity | Ton | 110 | |

| Rated tonnage point | mm | 6 | 3 |

| Stroke | mm | 180 | 200 |

| Die height | mm | 360 | 410 |

| Stroke per minute | s.p.m | 30-60 | 60-90 |

| Slide adjustment | mm | 80 | |

| Slide area | mm | 650×470×80 | |

| Bolster area | mm | 900×600×110 | |

| Main motor | kw.p | 11 | |

| Slide adjust device | HP | Electrical driving | |

| Air pressure | kg/cm2 | 6 | |

| Dimension (length×width×height) Presses dimension | mm | 1420×1985×3200 | |

| Presses weight | Ton | 10.5 | |

| Presses precision | GB(JIS) 1 class | ||

| Die cushion capacity | Ton | 6.3 | |

| Stroke of cushion die | mm | 80 | |

| Die cushion effective area | mm2 | 500×350 | |

| Name | Model | ||

| Type | Type V | Type H | |

| Capacity | Ton | 160 | |

| Rated tonnage point | mm | 6 | 3 |

| Stroke | mm | 200 | 90 |

| Die height | mm | 460 | 510 |

| Stroke per minute | s.p.m | 20-50 | 40-70 |

| Slide adjustment | mm | 100 | |

| Slide area | mm | 700×550×90 | |

| Bolster area | mm | 980×880×140 | |

| Main motor | kw.p | 15 | |

| Slide adjust device | HP | Electrical driving | |

| Air pressure | kg/cm2 | 6 | |

| Dimension (length×width×height) Presses dimension | mm | 1600×2200×3500 | |

| Presses weight | Ton | 17.8 | |

| Presses precision | GB(JIS) 1 class | ||

| Die cushion capacity | Ton | 10 | |

| Stroke of cushion die | mm | 80 | |

| Die cushion effective area | mm2 | 650×420 | |

| Name | Model | ||

| Type | Type V | Type H | |

| Capacity | Ton | 200 | |

| Rated tonnage point | mm | 6 | 3 |

| Stroke | mm | 200 | 100 |

| Die height | mm | 460 | 510 |

| Stroke per minute | s.p.m | 20-50 | 50-70 |

| Slide adjustment | mm | 110 | |

| Slide area | mm | 850×630×90 | |

| Bolster area | mm | 1140×820×160 | |

| Main motor | kw.p | 18 | |

| Slide adjust device | HP | Electrical driving | |

| Air pressure | kg/cm2 | 6 | |

| Dimension (length×width×height) Presses dimension | mm | 1750×2500×3900 | |

| Presses weight | Ton | 25.3 | |

| Presses precision | GB(JIS) 1 class | ||

| Die cushion capacity | Ton | 14 | |

| Stroke of cushion die | mm | 100 | |

| Die cushion effective area | mm2 | 710×480 | |

| Name | Model | ||

| Type | Type V | Type H | |

| Capacity | Ton | 260 | |

| Rated tonnage point | mm | 7 | 3.5 |

| Stroke | mm | 250 | 3.5 |

| Die height | mm | 500 | 150 |

| Stroke per minute | s.p.m | 20-50 | 550 |

| Slide adjustment | mm | 120 | |

| Slide area | mm | 950x700x100 | |

| Bolster area | mm | 1500x840x180 | |

| Main motor | kw.p | 22 | |

| Slide adjust device | HP | Electrical driving | |

| Air pressure | kg/cm2 | 6 | |

| Dimension (length×width×height) Presses dimension | mm | 2780x1850x4470 | |

| Presses weight | Ton | 32 | |

| Presses precision | GB(JIS) 1 class | ||

| Die cushion capacity | Ton | 14 | |

| Stroke of cushion die | mm | 100 | |

| Die cushion effective area | mm2 | 810×480 | |

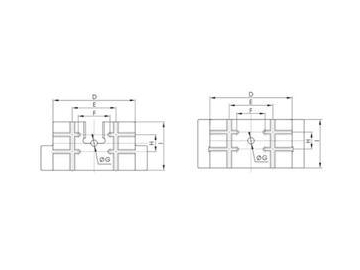

| Model | A | B | C | D | E | F | G | H | I |

| 360 | 180 | 150 | 560 | 300 | 220 | Φ50 | 180 | 420 | |

| 400 | 200 | 160 | 650 | 300 | 220 | Φ50 | 220 | 470 | |

| 440 | 220 | 220 | 700 | 300 | 175 | Φ65 | 220 | 550 | |

| 480 | 240 | 280 | 850 | 420 | 200 | Φ65 | 300 | 630 | |

| 520 | 260 | 290 | 950 | 420 | 200 | Φ65 | 300 | 700 |

| Standard | Optional |

| Inverter | Electrical automatic lubrication system |

| Hydraulic over-load protector | Pneumatic die cushion device |

| Slide adjust device | Preset counter |

| Die height indicator | Foot switch |

| Balance device | Quick die change device (Die lifter, clamp and die arm sepjes ) |

| Rotary cam switch | Slide knock-out device |

| Crank angle indicator | Misfeed detection consent |

| Electrical stroke counter | Power supply |

| Air source receptacle | Auti-vibration press mount |

| Against over-run safety device | Photo-electronic safety device |

| Maintenance tool box | Feeder |

| Uncoiler | |

| Leveler | |

| Mechanism hand | |

| Die room light | |

| Left (right) feeding device | |

| PAC 100 counter system | |

| Human-computer counter system |

Index

metal punching machine, power press, progressive stamping

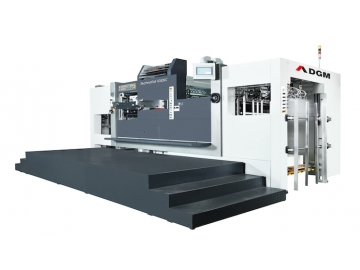

Related products

Send Message

Most Recent

More

Other Products

Videos