ZH Series High Head Slurry Pump

General introduction

ZH series pump is a kind of single stage, single suction, cantilever, double casing, horizontal centrifugal slurry pump for transporting strong abrasive slurry, which is suitable for low flow and high concentration working conditions, especially for the high head conditions where general single-stage pump is not applicable. This high head slurry pump is widely used in mining, metallurgy, electric power, chemical industry, paper making, building materials and other industries.

| Caliber (inch) | 1"-6" |

| Maximum flow quantity | 1152m³/h |

| Maximum head | 98m |

| Speed | 450-2200r/min |

| Power | 30-1200kw |

| Model | Maximum power through belt drive KW | Material | Clear water performance | ||||||

| Bushing | Impeller | Flow quantity Q | Head H | Speed n | Efficiency Eff | net positive suction head NPSH | |||

| (m³/h) | (l/s) | (m) | (r/min) | η% | (m) | ||||

| 30 | M | M | 16.2-34.2 | 4.5-9.5 | 25-92 | 1400-2200 | 20 | 2-5.5 | |

| 60 | M | M | 68.4-136.8 | 19-38 | 25-87 | 850-1400 | 47 | 3-7.5 | |

| 120 | M | M | 126-252 | 35-70 | 12-97 | 600-1400 | 50 | 2-5 | |

| 560 | M | M | 324-720 | 90-200 | 30-98 | 600-1000 | 64 | 3-8 | |

| 1200 | M | M | 576-1152 | 160-320 | 32-95 | 450-725 | 65 | 6-10 | |

Among them

For high density, strong abrasive slurry, the flow range is 40~80%;

For medium density, medium abrasive slurry, the flow range is 40~100%;

For low density, low abrasive slurry, the flow range is 40~120%.

For details, please refer to the bottom clear water performance table.

Features

1. Large diameter and short cantilever ensure the stiffness of the shaft to make the pump applicable for high power or severe working conditions.

2. The hardened stainless steel shaft sleeve and shaft adopts clearance fit, with O-rings at both ends, in order to protect the shaft from wear and corrosion.

3. The impeller has auxiliary blades on the front and rear cover plates, which can reduce the backflow as well as the sealing pressure. The impeller also adopts a wide flow channel and a concave blade design to improve the flow capacity and abrasion resistance, prolonging the service life.

4. The pump body and cover, made of ductile iron, have strengthening rib attached, guaranteeing the ability to withstand high pressure.

5. The flow parts are made of a variety of high chrome anti-abrasive alloys or rubbers with different properties, possessing the characteristics of abrasion resistance, corrosion resistance, impact resistance, erosion resistance and so on. The metal and rubber flow parts are interchangeable and can be in mixed use, to adapt to the requirements of different working conditions.

6. The shaft seal can use packing seal, auxiliary impeller seal, mechanical seal and other forms, in order to meet the sealing requirements of different working conditions.

7. The outlet position of the pump can be rotated to eight different angles (interval is 45 degrees) for installation and use as required.

8. Oil lubrication bearing assembly and grease lubrication bearing assembly are optional. The oil lubrication bearing assembly can effectively reduce the bearing operating temperature and failure caused by excessive temperature. The grease lubrication bearing assembly has the advantages of simple structure, reliable operation, easy installation, adjustment and maintenance.

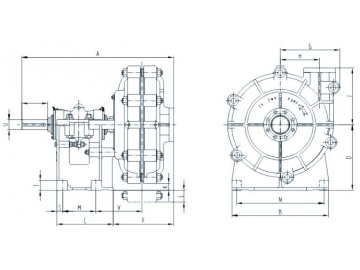

Outline drawing

| Pump model | A | B | C | D | U | E | F | G | H | J | K | L | M | N | S | T | V | Suction flange | Discharge flange | The anchor hole | Weight(Kg) | ||||||

| O.D | I.D | HOLES | P.C.D | 0.D | I.D | HOLES | P.C.D | ||||||||||||||||||||

| 759 | 406 | 311 | 254 | 42 | 121 | 306 | 270 | 194 | 254 | / | 11 | 175 | 356 | 32 | 48 | 252 | 152 | 38 | 4-ø17 | 114 | 152 | 25 | 4-ø17 | 114 | 4-ø19 | 318 | |

| 986 | 492 | 364 | 330 | 65 | 164 | 389 | 384 | 254 | 368 | / | 51 | 213 | 432 | 38 | 64 | 298 | 216 | 76 | 8-ø19 | 178 | 203 | 51 | 4-ø19 | 165 | 4-ø22 | 750 | |

| 1240 | 622 | 448 | 457 | 80 | 222 | 492 | 492 | 330 | 432 | 2 | / | 257 | 546 | 54 | 76 | 381 | 254 | 102 | 8-ø19 | 210 | 254 | 76 | 8-ø19 | 210 | 4-ø29 | 1250 | |

| 1556 | 857 | 635 | 610 | 100 | 279 | 584 | 616 | 413 | 546 | 26 | / | 349 | 762 | 95 | 98 | 470 | 337 | 152 | 8-ø22 | 292 | 305 | 102 | 8-ø22 | 260 | 4-ø35 | 2531 | |

| 2275 | 1150 | 1040 | 650 | 150 | 350 | 852 | 835 | 584 | 813 | / | 160 | 880 | 900 | 80 | 125 | 538 | 432 | 203 | 8-ø29 | 375 | 432 | 152 | 8-ø29 | 375 | 4-ø48 | 6586 | |

| 1700 | 920 | 780 | 450 | 120 | 280 | 622 | 625 | 415 | 615 | / | 155 | 640 | 760 | 70 | 90 | 382 | 380 | 152 | 8-ø27 | 320 | 420 | 150 | 8-ø27 | 360 | 4-ø35 | 3450 | |