Flexible Beam Coupling, Slit Coupling

The beam couplings are usually made of aluminum alloy and stainless steel and feature spiral and parallel cut designs. The parallel misalignment can be improved due to multiple beam cuts. These couplings generally feature an excellent flexibility and a lower price, as well as a zero backlash and zero need for maintenance.

The beam couplings are classified into two series: helical beam coupling and parallel slit coupling. The helical beam couplings feature a continuous multi spiral cuts, and are known for the large flexibility that allows the beam to compensate for a higher misalignment, as well as compensate for a parallel, angular, and axial misalignment. The helical shaft coupling has a small torsional stiffness and it is suitable for small torque applications, such as encoders and XY stages.

A parallel slit coupling reduces the beam length without sacrificing any of its ability to absorb misalignment. The slit is distributed in a regular manner, and will increase the stiffness of the coupling and ensure it is able to undertake a large torque without losing its ability to absorb the misalignment. The beam coupling is suitable for light load applications, such as the connection of servo motors or stepping motors with a screw rod.

- Rated torque :0.2-0.9 N.m

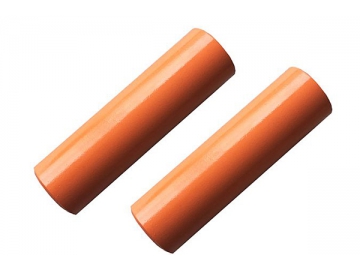

Parallel slit coupling

Aluminum alloy -

- Rated Torque: 0.2-0.9 N.m

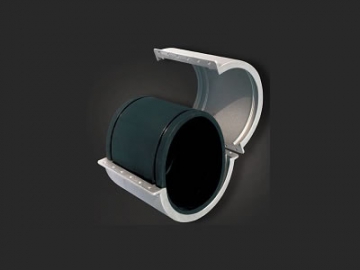

Helical beam coupling

Aluminum alloy

- Rated Torque: 0.2-0.9 N.m

-

- Rated Torque: 0.5-14 N.m

Parallel slit coupling, set screw type

Aluminum alloy

- Rated Torque: 0.5-14 N.m

-

- Rated Torque: 0.5-14.0 N.m

Helical beam coupling, set screw type

Aluminum alloy

- Rated Torque: 0.5-14.0 N.m

-

- Rated Torque: 0.5-14.0 N.m

Parallel slit coupling, clamp type

Aluminum alloy

- Rated Torque: 0.5-14.0 N.m

-

- Rated Torque: 0.5-14.0 N.m

Helical beam coupling, clamp type

Aluminum alloy

- Rated Torque: 0.5-14.0 N.m

-

- Rated Torque: 0.5-38 N.m

Parallel slit coupling, set screw type

Aluminum alloy

- Rated Torque: 0.5-38 N.m

-

- Rated Torque: 0.5-38 N.m

Parallel slit coupling, clamp type

Aluminum alloy

- Rated Torque: 0.5-38 N.m

-

- Rated Torque: 0.5-38 N.m

Parallel slit coupling, keyway type

Aluminum alloy

- Rated Torque: 0.5-38 N.m

Applications:

The beam couplings are used in CT scan, laser marking device, confectionery equipment, automatic rotation stage, matching box for RF power, 3D printer, food processing equipment, index table, etc.

- The beam coupling is a one-piece coupling and it has faster response speed.

- Zero backlash

- The clockwise and counterclockwise rotation characteristic is identical.

- It can be fastened by set screw and clamping screw.

GZLINK is focus on the production of precision coupling more than 20 years. We control the quality of every step in the production process. Every shaft coupling has a unique code, so it is convenient for us to track. We have good cooperation relationship with our thousands of customers from America, Japan, Germany, Malaysia and other countries. You can choose the product you need in the product list. If you do not find the coupling you need, please contact us and we can customize your precision coupling.