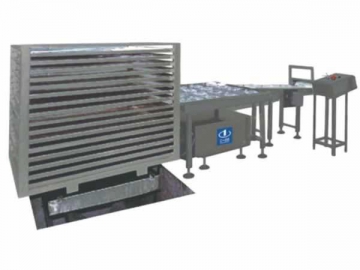

Liquid Filling, Nitrogen Filling and Stoppering Machine

The machine can perform liquid filling, nitrogen filling and stoppering operations under room temperature and high temperature. Although it is mainly used for infusion liquids like glucose and antibiotics, the machine is also suitable for amino acids, fat emulsion, oral liquid, nutrition liquid and biological agents.

The liquid filling, nitrogen filling and stoppering machine is designed and made with hygienic and safety requirements in mind, meeting GMP requirements. During filling process, no forced friction of mechanical parts avoids particulate pollution. In addition, possible pollution caused by long distance delivery of infusion bottles is eliminated, as nitrogen filling is immediately performed after liquid filling and stoppering is instantly completed after nitrogen filling. Moreover, the CIP (clean-in-place), SIP (sterilization-in-place) unit enables the machine to be thoroughly, easily cleaned and sterilized.

- The liquid filling, nitrogen filling and stoppering machine uses Germany GEMU pneumatic diaphragm valves for high filling accuracy. If there is no bottle, it will not perform filling operation, resulting in no waste of liquid.

- The filling heads allows for easy assembly and disassembly. In fact, users just need to loosen two M6 bolts for disassembly purpose. In addition, adopting mobile structure, the bottle inlet screw can be easily replaced with screw of different specification by only removing and installing two M8 × 25 bolts, which greatly facilitates change of infusion bottles in different sizes.

- The liquid level gauge in the filling barrel provides high sensitivity. Kept away from the liquid inlet, it will not be affected by the inlet tube during liquid filling. Additionally, the liquid filling, nitrogen filling and stoppering machines stably rotate at low speed, which contributes to the smooth liquid level, thus ensuring the stability of the pressure in the filling barrel.

- The machine is easy to operate. Parameters can be set and modified on the man-machine interface. Using advanced PLC and variable frequency control technologies, the electronic control system ensures smooth, convenient startup, shutdown and specification change operations.

- There is nitrogen protection in the delivering star wheel between the nitrogen filling star wheel and the stoppering star wheel. The nitrogen filling adopts the insert bottle filling methods, maximally maintaining the residual oxygen of the nitrogen filling products.

- The machine adopts vacuum stoppering and mechanical positioning. Only after the stoppers are in the accurate place, the stoppering operation can be performed, which helps improve qualification rate.

| Model | CNGFS16/10 | CNGFS24/10 | CNGFS36/20 | CNGFS48/20 |

| Applicable size | 50 ml, 100 ml, 250 ml, 500 ml | |||

| Capacity | 60-150 bottle/min | 120-250 bottle/min | 200-350 bottle/min | 350-500 bottle/min |

| Filling heads | 12 | 20 | 26 | 30 |

| Nitrogen filling heads | 10 | 10 | 20 | 20 |

| Stoppering heads | 10 | 10 | 20 | 20 |

| Metering error | ±1.5% (standard container) | |||

| Electric capacity | 4.0 kW | 4.0 kW | 4.0 kW | 4.0 kW |

| Compressed air consumption | 1.5 m³/h (0.6MPa) | 2.0 m³/h (0.6MPa) | 3.2 m³/h (0.6MPa) | 4.5 m³/h (0.6MPa) |

| Outer dimension (mm) | 2500X1250X2350 | 2350X1520X2350 | 3150X1900X2350 | 3500X2350X2350 |

Note: In the above table, the capacity is inversely proportional to the bottle size. Hence, the bigger the bottle size, the lower the capacity. The specific details are correct based on the tender documents.

As a China-based liquid filling, nitrogen filling and stoppering machine manufacturer and supplier, IVEN Pharmatech offers a broad range of products that includes liquid filling and stoppering machine, soft infusion bag drying machine, vial capping machine, and more.