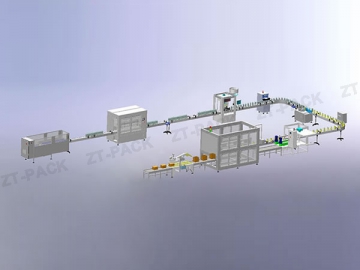

Corrosive Liquid Filling Machine

The corrosive liquid filling machine is a fully corrosion resistant filling system specially designed for filling corrosive liquids. It is ideal for automatic filling of 50 to 50,000mL of low viscous liquids. Without having to change parts, users can easily fill different bottle types with this machine. Machine cleaning is easy using plain water and requiring no special cleaners or chemicals. All parts that come into contact with liquid materials are made of a non-metal, corrosion resistant material. The diving nozzle also features an accurate measuring unit to ensure no bubbles and no leakage.

- The corrosive liquid filling machine is made of heavy-duty plastic.

- Parts that come into contact with liquid to be filled are made of PVC or PU. These parts include the plastic liquid storage tank, acid resistant conveyor, automatic level induction system with floating ball and protection unit.

- The fill head is easily adjusted to meet requirements for different bottle heights.

- It features a pneumatic bottle blocking unit with bottle feeding counter and discharging counter.

- This filling machine is capable of filling large volume bottles in several steps.

- PLC controlled with an HMI touchscreen.

- Quick connect accessories are made of an easy-to-clean stainless steel.

- The bottle clamping unit is designed for bottles with a thin neck.

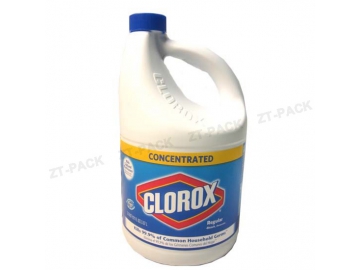

The corrosive liquid filling machine is used to fill bottles with bleach, toilet cleaner, acid, chlorine, NaClO, sulfuric acid, 84 disinfectant, glue and strong acid. It is applicable for different bottle shapes and irregularly shaped bottles.

| Capacity | 7200 (100ml) b/h |

| Filling Volume | 50-1000ml |

| Measurement Precision | ±1% |

| Applicable Bottle Diameter | 40-100mm |

| Applicable Bottle Height | 60-300mm |

| Air Pressure | 0.6-0.8Mpa |

| Total Power | 1.5Kw |

| Voltage | AC220V, 50/60Hz |

| Net Weight | 750kg |

| Dimension | 2000(L)×1030(W)×2300(H)mm |

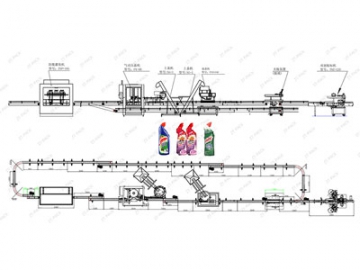

| Model | ZGP-6G | ZGP-8G | ZGP-10G | ZGP-12G | ZGP-16G |

| Dimension | 2000×710×2200mm (L×W×H) | 2200×710×2200mm (L×W×H) | 2300×710×2200mm (L×W×H) | ||

| Filling Head | 6 | 8 | 10 | 12 | 16 |

| Capacity (1L) | 1800B/H | 2000 B/H | 2800 B/H | 3200 B/H | 4500 B/H |

| Power | 1KW | 1 KW | 1KW | 1.5KW | 1.5KW |

| Suitable Bottle | Diameter: Φ40mm——Φ100mm Height: 80mm——280mm | ||||

| Filling Accuracy | ≤100ml: -1.5ml | ||||

| 100-500ml: -2ml | |||||

| 500-1000ml: -3ml | |||||

| Neck Diameter | Φ18mm | ||||

| Filling Range | 50ml——1000ml | ||||

| Air Pressure | 0.6Mpa | ||||

| Power Supply | 220V, 50HZ | ||||