Annealing Oven

Tube annealing oven

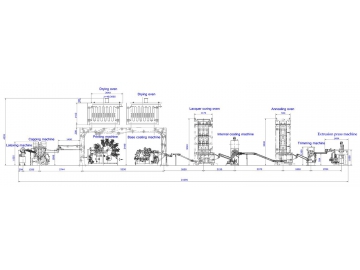

Description of production

THG01/THG02 This annealing oven is the associated equipment of aluminum tube machine line. There are two models gas and electricity of energy has for customers to choose.

After the aluminum slug is formed into tube by cold extrusion, it loses flexibility because of the stress produced by the change of the structure of metal molecular. Therefore, in order to eliminate this stress and make the tubes body meet the requirements, the de-stressed annealing treatment for tube billet must be performed. The annealed aluminum tube becomes very soft and the mold discharging agent on the surface of the tube was evaporated to ensure the adhesion of inner-coating and base-coating.

This model of annealing oven uses the heating form of gas and hot air circulation, which are clean and energy saving. The conveyor chain places the tube billets one by one into the "C"type ship, and enters the annealing oven in turn through the annealing oven trough. The tube billet followed the "C" type ship to circulate in the chamber of oven, and the annealing was completed after 3 to 5 minutes of high temperature in the annealing oven. Then the tube billet is poured out at the outlet after annealing, which is sent to the cooling zone and sent to the next process by the conveyor chain. The outlet link can be connected with the conveying equipment of other equipment into the next process.

Technical parameter- Suitable diameter of tube:16-25mm25-35mm

- Maximum suitable length of tube:200mm

- Production rate:120 tubes/minute

- Operating temperature:200-450

- Dimension:4250*1400*2500mm

- Net weight:5000Kg

- The annealing oven for aluminum tube is controlled by PLC and can control the temperature automatically. The SCIO burners can automatically adjust the flame size according to the temperature change in the oven. The FUJI temperature controller ensures temperature within the plus or minus 2 of set temperature.

- The heating box, wind turbine and wind form the hot air circulation system. The box is equipped with convection stirring technology, so the temperature is very even. The hot air is continuously circulated in the chamber of oven after loop transportation and the temperature in the heating oven is even, so the annealing effect is good and the product quality is high.

- The machine has the advantages of safety, convenience, environmental protection and energy saving. Both natural gas and liquefied petroleum gas can be used. This machine uses gas heating, which has the advantage of low cost and fast heating.

- The feed conveying chain adopts continuously variable regulation, which can make the equipment synchronized with the production speed of the front-end equipment. The main driving force of the chain in the oven is provided by the spraying machine.

- The suspended structure of the chamber of oven facilitates maintenance and makes the operation of the conveyor ship more balanced. It reduces the phenomenon of cans being dropped and broken, thus improving the qualification rate of the product.

Electric annealing oven

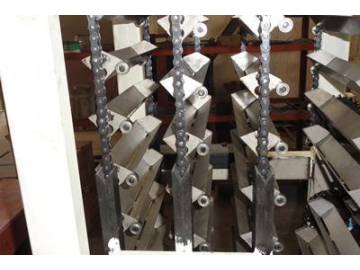

Electric annealing oven  C"C" type ship chain

C"C" type ship chain  Drying oven

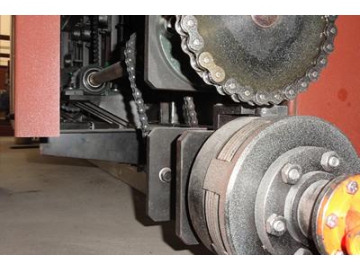

Drying oven  Chain transmission mechanism

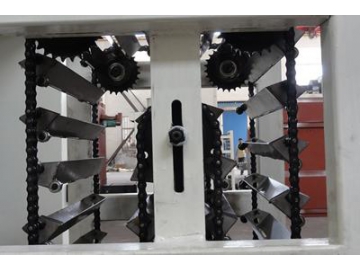

Chain transmission mechanism  Chamber of oven

Chamber of oven