Tube Filler and Sealer GRRB-H3-3060A (high viscosity liquid / paste packaging with color mixing)

Request a Quote

Application

This tube filler and sealer is usually used to fill high viscous pastes, such as silicone sealant, modified saline adhesive, polyurethane sealant, photovoltaic sealant, etc.

Description

This filler is modified based on the GRRB-3060A tube filler, adding a color mixing system. So it can mix different colors of sealants and then fill the mixed product. It is an integrated packaging equipment, having functions of aluminum composite film hot sealing, metering with static mixer and clipping. This tube filler should be used together with a static mixer.

Technical parameters

| Filling speed | 20-25 cartridges/min |

| Filling accuracy | ±2g/590ml |

| Filling range | 280ml-600ml (customization is offered for larger capacity) |

| Overall power | 3KW (about 2.5KW when coupled with3K static mixer) |

| Gas pressure | 0.7MPa |

| Gas consumption | 100L/min |

| Working pressure of hydraulic system | 7-9Mpa |

| Machine size (L x W x H) | 1380x1100x1800mm |

| Net weight | 0.8T |

Note: Great can match the equipment’s voltage and frequency for clients in different locations.

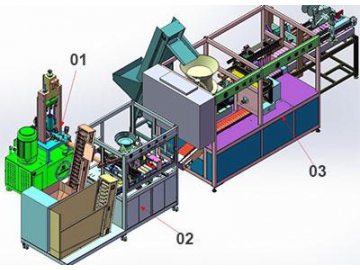

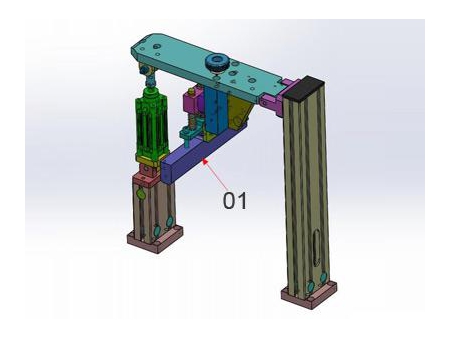

Structure

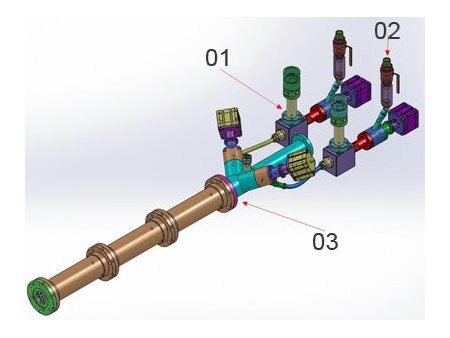

- Automatic filling (cooperating with the static mixer)

01: Mixing mechanism

01: Mixing mechanism

02: Metering mechanism

03:Aluminum film hot sealing

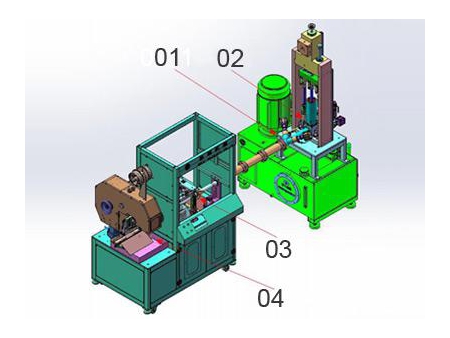

04: Clipping mechanism - Measuring system

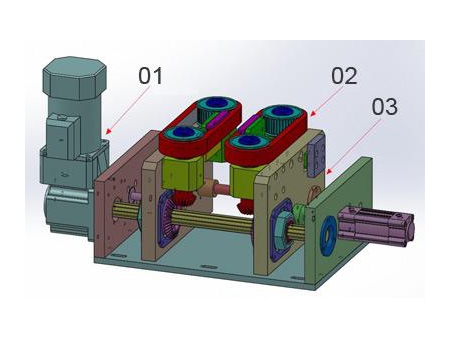

01: Hydraulic squeezing system

01: Hydraulic squeezing system

02: Base material metering system

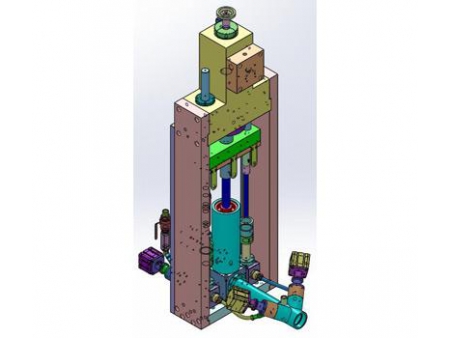

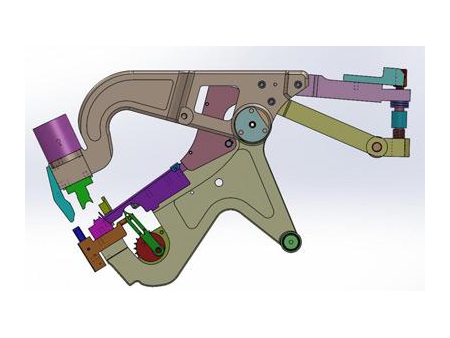

- Mixing system

01: Additive metering

01: Additive metering

02: Aase inlet

03: Static mixing system - Aluminum film transporting

01:Gear motor

01:Gear motor

02:Film conveying belt

03:Film feeding clip - Products discharge mechanism

01: Products rotating mechanism

01: Products rotating mechanism - Automatic clipping

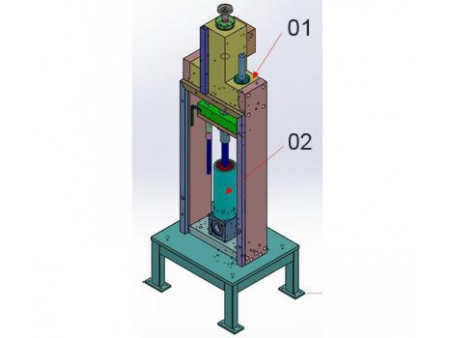

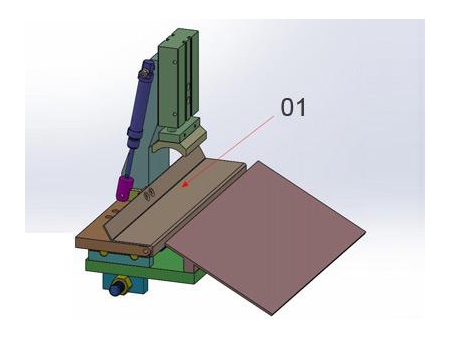

- Aluminum film hot sealing device

01: Hot sealing mould

01: Hot sealing mould - Automatic code-printing

- Filling volume adjustment is available in manual and automation

- Fault warning and displaying

Related products

Send Message

Most Recent

More

Other Products

Videos