Prestressed Concrete Electric Pole Mould

concrete spun pole mould, spc pole mould, concrete electric pole mold

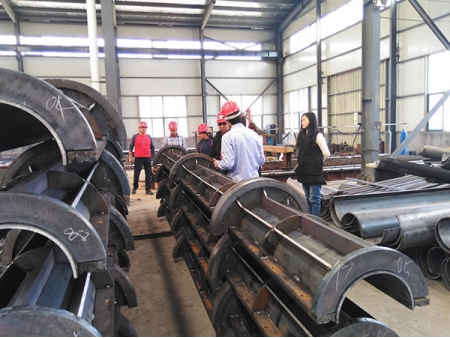

Concrete electric spun pole mould is the most important concrete pole forming equipment in concrete pole factory. It’s designed and manufactured according to concrete pole specifications. Its length ranges from 6m to 18m, diameter from 110mm to 350mm. We can also customize other specification of concrete pole mould according to request of customers. Concrete pole mould rotates on centrifugal spinning machine with speed from 400RPM to 600RPM with motor speed from 1100RPM to 1960RPM. So, there is high demand on concrete pole straightness and quality. Concrete spun pole mould is made of 10mm steel plate and running wheels are made of 45# casting steel. We can manufacture concrete pole mold with no joint within 18m mould. It’s unique in whole Asia area.

Conical concrete pole moulds offered by our company exactly reach the dimension requirements and has a compact structure, convenient to install and disassemble. What’s more, its strength and rigidity is impressive.

Main Parts-

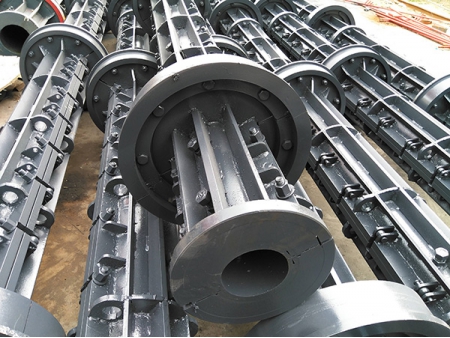

Flange connection

-

Wheel, bolt fixed and detachable

-

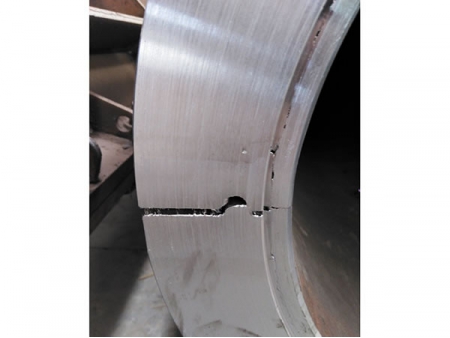

Tongue-and-groove joint

1. Welding:We imported carbon-dioxide welding machine from Japanese Panasonic Company, in order to guarantee the welding quality.

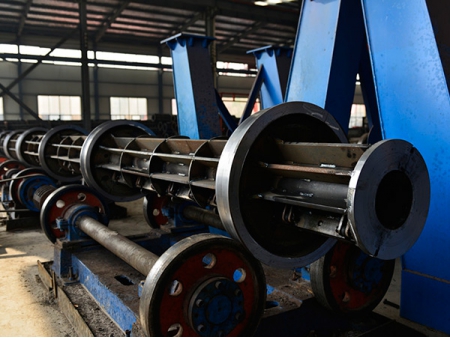

2. Centrifugal Test :Before leaving the factory, every mould must undergo high-speed centrifugal rotation test conducted by the centrifugal test platform. If the mould bounces up during the rotation, the mould will be sent back for re-processing.

3. Straightness Test :The straightness is a key parameter of conical concrete pole mould. If the straightness value is more than 1 degree, the service life will be greatly decreased.

4. Collar Wheel:We also manufacture and provide high-quality collar wheels, which functions as a stop device for the pole mould.

-

One body without flange connection

One body without flange connection -

Welding test

Welding test -

Centrifugal test

Centrifugal test

-

Straightness test

Straightness test -

Collar wheel

Collar wheel -

Smooth wheel

Smooth wheel

Features of Conical Concrete Pole Mould

1. The concrete pole must be low leakage, convenient to operation and easy to process. The tongue-and-groove pole has a great sealing performance but sands may get into the groove easily, making it's difficult to clean.

2. The conventional assembled wheel is easy to fall off as the bolt is easy to unscrew and break off. In our conical concrete pole mould, the wheel is welded and makes use of A3 steel plate as raw materials, increasing the intensity and security.