Coiler Machine for Wheel Rim

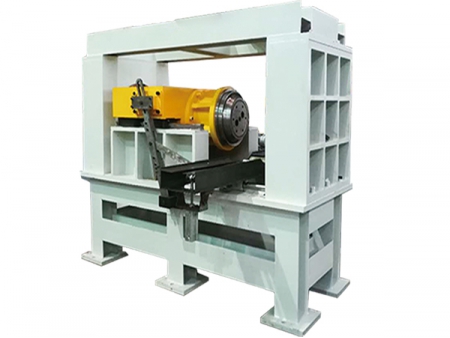

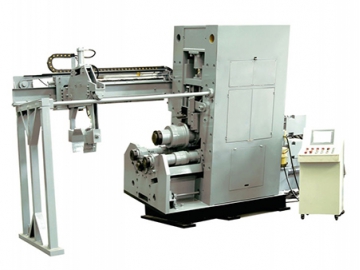

As a major wheel rim machinery manufacturer, we supply a variety of equipment, including the coiler machine for the wheel rim production line. This rim machine set consists of the feeder, deburrer, stamper and coiler.

Functions of each part

1. The feeder is used to manually feed a single piece of a rim band.

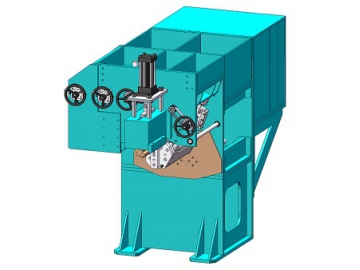

2. The deburrer is equipped to remove burrs at both edges of the rim band, protecting molds and operators from scratches during the next processing steps.

3. The stamper presses the needed marks on the rim band, including specification, model, manufacturer production date and other information.

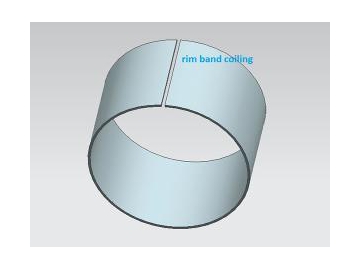

4. The coiler is a wheel rim forming machine used to automatically coil the cut to length rim bands.

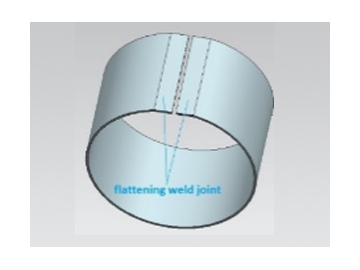

5. Flattening weld joint of both edges, it is conducive to weld clamping on next step.

- Setp1, feeding

- Step2, deburring

- Step3, stamping

- Step4, coiling

- Step5, flattening

Main Features of the Coiler Machine

1. Therim equipment has a horizontal structure, chain transmission, and hand wheel for adjustment. This ensures the easy operation and maintenance.

2. The stamping head on the stamper can be quickly changed according to different needs.

3. The discharge end can be designed with an automatic discharging platform that is conducive to the automatic transportation of the work piece.

4. The wheel rim coiler machine features an integrated design, that melds deburring, stamping and coiling into one machine, saving labor and floor space.

5. The main shaft is engineered from the NSK brand high performance bearing, ensuring the long service life.

6. The horizontal coiler machine uses an electrical control system from Schneider, making it safe and reliable.

7. The coiler used in the small wheel rim line is able to flatten the welding joint. After it has been formed into a coil, the work piece can be directly conveyed to the butt welding process.

8. The coiler can provide automatically and manually feeding function based on customer demand.

| Applications | Passenger Car | Commercial Vehicle | agricultural vehicle | |

| Rim diameter range | 13 to 17 inches | 17.5 to 26 inches | 20 to 54 inches | |

| Rim band thickness | ≤ 4mm | ≤ 8 mm | ≤ 8 mm | |

| Rim band width | 3 to 10inch | 5.5 to 16inch | 7 to 28inch | |

| Main machine specifications | Feeder | Available | Available | Available |

| Deburrer | JMC-100 | JMC-100 | JMC-100 | |

| Stamper | DZJ-120 | DZJ-120 | DZJ-120 | |

| Coiler | QYJ-600 | QYJ-800 | QYJ-1500 | |

| Input power | Deburrer power | 4 Kw | 5.5Kw | 5.5 Kw |

| Coiler power | 7.5 Kw | 11Kw | 11Kw | |

| Total input power | 11.5 Kw | 16.5Kw | 16.5Kw | |

| Coiling roller diameter | 155mm | 165mm | 175mm | |

| Coiling roller speed | 88r/min | 63r/min | 63r/min | |

| Power supply | AC 380V/3phase/50Hz, Can be customized | |||

Passenger Car

Rim diameter range:13 to 17 inches

Rim band thickness:≤ 4mm

Rim band width:3 to 10inch

Feeder:Available

Deburrer:JMC-100

Stamper:JMC-100

Coiler:QYJ-600

Deburrer power:4 Kw

Coiler power:7.5 Kw

Total input power:11.5 Kw

Coiling roller diameter:155mm

Coiling roller speed:88r/min

Power supply:AC 380V/3phase/50Hz, can be customized

Commercial Vehicle

Rim diameter range:17.5 to 26 inches

Rim band thickness:≤ 8 mm

Rim band width:5.5 to 16inch

Feeder:Available

Deburrer:JMC-100

Stamper:DZJ-120

Coiler:QYJ-800

Deburrer power:5.5Kw

Coiler power:11Kw

Total input power:16.5Kw

Coiling roller diameter:165mm

Coiling roller speed:63r/min

Power supply:AC 380V/3phase/50Hz, can be customized

Agricultural Vehicle

Rim diameter range:20 to 54 inches

Rim band thickness:≤ 8 mm

Rim band width:7 to 28inch

Feeder:Available

Deburrer:JMC-100

Stamper:DZJ-120

Coiler:QYJ-1500

Deburrer power:5.5 Kw

Coiler power:11Kw

Total input power:16.5Kw

Coiling roller diameter:175mm

Coiling roller speed:63r/min

Power supply:AC 380V/3phase/50Hz, can be customized

Passenger Car

Rim diameter range:13 to 17 inches

Rim band thickness:≤ 4mm

Rim band width:3 to 10inch

Feeder:Available

Deburrer:JMC-100

Stamper:JMC-100

Coiler:QYJ-600

Deburrer power:4 Kw

Coiler power:7.5 Kw

Total input power:11.5 Kw

Coiling roller diameter:155mm

Coiling roller speed:88r/min

Power supply:AC 380V/3phase/50Hz, can be customized

Related Names

Rolling Machine For Wheel Rim