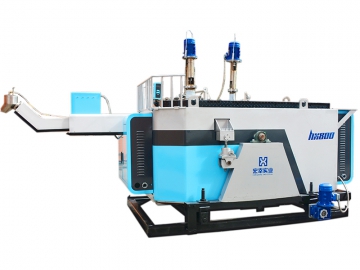

Electric Magnesium Holding Furnace

Request a Quote

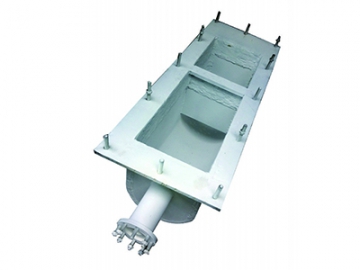

This electric magnesium holding furnace was designed based on many years of industry experience. The furnace weighs 1500kg and is available for hot or cold chamber die casting operations.

Design specifications

- Melting rate: 350-400kg/h

- Total capacity of crucible: about 1500kg

- Reasonable loading capacity of magnesium liquid: about 1300kg

- Process temperature: 680°C- 690°C

- Technical function: carries out the automatic quantitative pouring of molten magnesium

-

Configuration standard: compatible with 1650T die casting machines - Total power of furnace: 289KW

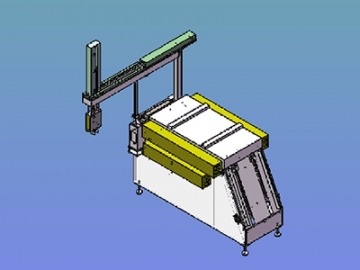

- Motor controlled forward and backward movement. The lift table can be configured separately.

- Siemens PLC computerized control system integrates all functions for the operation of the die-casting enterprise.

- Quantitative parameters: a minimum of 100g, a maximum of 20kg, with the weight controlled by quantitative frequency and pumping time.

Features

- The crucible is made of 31mm thick bimetallic composite steel, and the melting chamber is separated from the holding chamber to ensure the purity of the magnesium liquid and the stability of the temperature within the pump chamber.

- Parallel feeding pipe is designed to ensure that the magnesium liquid is on standby in the die casting barrel. The material of the feeding pipe can withstand temperatures up to 1250 °C and can be directly heated to 760 °C, effectively preventing the feeding pipe from blockage.

- Compatible with magnesium alloy automatic feeding preheaters. Advanced manipulator feeding is adopted to prevent the spitting and splashing of materials.

- The crucible and the feeding pipe is connected by flanges with high sealing performance, thus preventing unnecessary waste of molten magnesium.

- It can be combined with an automatic nozzle feeder to automatically recover the nozzle material to reduce labor costs.

- The internal parts of the crucible where the molten magnesium comes in contact with the air are welded with 8 layers of stainless steel to enhance the corrosion resistance and the service life of the crucible.

- The power of the melting chamber is 160KW and the power of the holding chamber is 120KW, which can effectively improve the heat transfer of the melting furnace and minimize power loss.

- The holding furnace has the functions of overheating alarm and low-temperature alarm. These levels can be customized.

- The gas fired holding furnace is equipped with a liquid leakage detecting device.

- The magnesium furnace has its own communication interface that can be turned off or maintained in manual state without affecting the signal of the die-casting equipment.

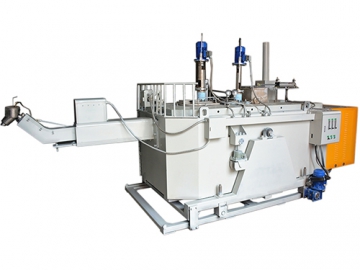

Configuration

- One furnace

- One crucible

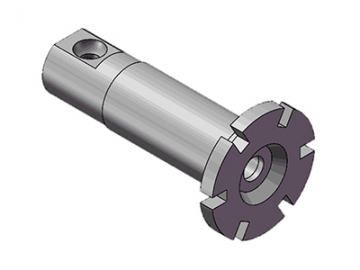

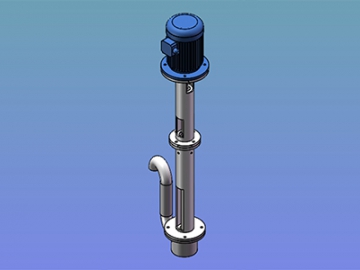

- One metering pump

- One delivery pump

- One feed delivery pipe

- One electric control cabinet

- One set of base support

- Batch feeder (optional)

Electric cabinet

Electric cabinet Batch feeder

Batch feeder Counter flange

Counter flange Feed delivery pump

Feed delivery pump Metering pump

Metering pump Crucible

Crucible

Furnace structure

- The casing is made from processed A3 steel plate and profile steel.

- The insulation layer is composed of high-quality Nano-plate, insulation material and calcium silicate board, which are laid in the outer enclosure.

- The furnace lining is made of imported light mullite insulation bricks.

- The internal parts of crucible where the magnesium liquid is in contact with the air are welded with 8 layers of stainless steel to enhance the corrosion resistance and the service life of the crucible.

- The furnace wire is flat belt heating wire made of ocr27Al7M02, which is fixed in the wall and bottom of the hearth for heating, with the heat-resistance temperature up to 1400°C.

- Fixed U-shape furnace nail

- A liquid leakage alarm device is equipped in the furnace, whose electrode is connected with the alarm system of the electric furnace control cabinet, so the furnace can be shut down if the signal alarms.

- The protective-gas system should be turned on until the temperature of the molten magnesium drops below 350 degrees, and the crucible can’t be lifted out for maintenance until the molten magnesium is naturally cooled to a solid state.

Resistance wire

Resistance wire U-shape furnace nail

U-shape furnace nail Protective casing

Protective casing

The insulation system is composed of:

- Two layers of high temperature insulation boards (Morgan-imported)

- Three layers of insulated cotton with the density of 260

- High-purity high-temperature insulating brick: mullite (Morgan-imported)

- Nano insulation material

Related products

Send Message

Most Recent

More

Other Products

Videos