Capabilities

KLF specializes in the production of a variety of precision springs with a wire diameter of 0.1mm to 6mm, such as compression springs, button springs, torsion springs, wire springs, extension springs, battery springs and more. These springs are then used in appliances, computer equipment, office equipment, sports equipment, household appliances, kitchen appliances, sanitary ware, stationery, toys and other industries.

How does KLF’s customization service work?- Raw material

KLF makes springs using high carbon steel wire, stainless steel wire and non-ferrous metal alloy wire, including ASTM A228 high carbon steel wire, AISI 302/304 stainless steel wire, AISI316 stainless steel wire, phosphorous bronze (grade A) wire, beryllium copper wire and more. We offer customized springs according to actual customer needs, so long as they inform us the environment their products will be used in, and provide corresponding specifications.

The following are the characteristics of different materials:

- ASTM A228 high carbon steel wire spring

High carbon steel wire, is mainly used to make small springs with a high tensile strength and strong corrosion resistance. In addition, high carbon steel wire is an ideal choice for recycling applications due to its ability to withstand a higher load stress than other spring materials, and can be electroplated after molding. - AISI 302/304 stainless steel wire spring

It is a common spring material with an excellent tensile strength, corrosion resistance and heat resistance. AISI 302/304 stainless steel wire springs are widely used for sporting equipment and automotive fields. - AISI316 stainless steel wire spring

316 stainless steel has a better corrosion resistance than 302/304 stainless steel, but a lower tensile strength and better cold forming performance. AISI316 stainless steel wire springs are suitable for corrosive environments, such as medical devices where a high impact or load strength is not needed. - 17-7 PH (AISI 631) stainless steel wire spring

17-7 PH (AISI 631) stainless steel is better than most spring materials for use in extreme conditions. It will extend the service life of whatever it is used in, and features an excellent fatigue and corrosion resistance. - Phosphorous bronze (grade A) wire spring

Phosphor bronze has an excellent electrical conductivity and corrosion resistance. Phosphor bronze wire springs are mainly used in the electrical industry, but are not suitable for use in high impact or high load applications because of its cold drawn process. - Beryllium copper wire spring

Beryllium copper wire springs are used in electrical applications requiring a high impact strength and corrosion resistance due to their excellent electrical conductivity, corrosion resistance and strength that is consistent with alloy steel.

- ASTM A228 high carbon steel wire spring

- KLF provides customized springs with the following equipment

The process of spring manufacturing generally includes coiling, winding, heat treatment, pressing, grinding, chamfering, shot blasting, finishing, assembly and so on. KLF is well equipped with various processing equipment for spring production, such as lathes, spring coiler, ultrasonic cleaning machine, tempering furnace, etc.

- Lathes: Turning for spring internal and external thread, end face. Can also be equipped with a drill, reamer, die and more.

- CNC automatic spring machine: Used for the production of a variety of springs, including extension springs, compression springs, conical spring, double torsion springs and other special springs with a wire diameter from 0.1mm to 3.0mm through extrusion, stamping and forming processes.

- Camless spring former: Used for producing extension spring, compression spring, conical spring, double torsion spring and other special springs with wire diameter from 0.1mm to 2.0mm. Its special camless design enables production of a variety of springs with stable performance.

- Spring coiler for compression spring: Used for producing compression spring, conical spring and other springs with wire diameter from 0.1mm to 1.5mm.

- Ultrasonic cleaning machine: Cleans springs by destroying insoluble dirt and dispersing the stain in the cleaning fluid.

- Tempering furnace: Used for general parts tempering after quenching and quenching, annealing and aging heat treatment of piecework such as aluminum alloy die casting.

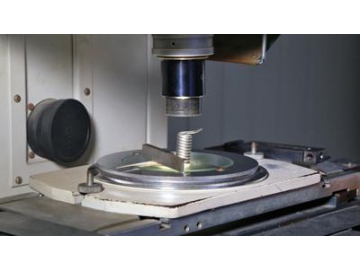

- Quality control

To ensure quality control, KLF’s products are not only certified to ISO9001 standards, but have also undergone extensive testing, including a DC test, life test, tension test, and salt spray test.

DC low resistance tester

It can quickly and accurately measure the transformer winding DC resistance. Test the induction button spring’s resistance to ensure it operates normally on a PC board (circuit board) without damaging other parts.TCD-CNC automatic pull pressed spring testing machine

It is used to test the fastening degree and torsional resistance of spring samples to determine whether or not the springs meet the torsional force need. The torsion force is important for qualified applications of equipped products.Manual tension tester

Used for tension testing of the extension spring and compression springSolder machine

Used for detecting the outline and surface shape of various complex workpieces.Life tester

Using professional torsion spring life tester, the machine is turned on a few days after placing the torsion spring inside of it. The inspector will then observe the number of times the spring turns, and offer that information to the customers.Salt spray tester

Used for spring testing of surface treatment and corrosion resistance.