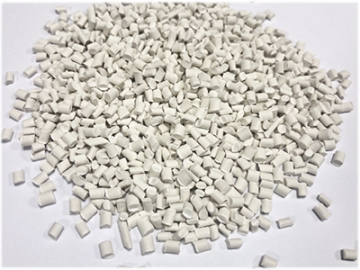

Plastic Film Additive Masterbatch

Introduction

Plastic film additive masterbatch is compounded by a variety of additive formulations. After dispersion, it effectively improves the adhesion resistant properties of films in polyolefin products (opening performance) and lubricating properties, which thus results in an improvement and promotion of the production process and film quality.

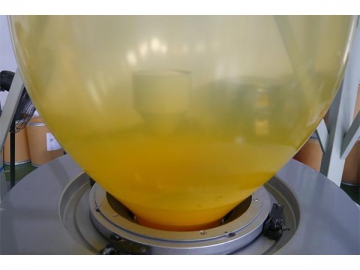

Modern plastic processes are continuously developing in terms of automation, speed and quality. The faster the processing of plastic products is, the easier it is for static electricity to form through friction. This is even more obvious in film blowing processes, and can easily cause adhesion between films, which impacts high speed extrusion, and all resultant film and packaging processes. Thus, adding a plastic film masterbatch in the proper manner during the blowing process can prevent the formation of static to begin with, as well as improves the processing performance of plastic and opening performance of film, prevents adhesion between films, increases the handling ability of the film and molding of the products, and improves the surface finish on products.

Feature

1. This masterbatch can effectively improve anti-adhesion properties of films (the opening performance) and lubricating properties during the production process.

2. It can improve coking on the equipment die, and reduce the cleaning frequency of the die.

3. Reduce crystal points on the film and improve the stability of film thickness.

4. Reduce or avoid accumulation of non-metallic carbides in the screw for long periods of time.

5. Reduce energy consumption of equipment with the same capacity, and increase capacity in equipment with the same energy consumption.

6. In normal addition ratios, it will not affect the original film transparency.

Attention

The functional masterbatch also functions as a cleanser for non-metallic carbides found in equipment (such as equipment that has never used a masterbatch). Impurities cleaned out may form more crystal points on the film, so we recommend adding a second functional masterbatch after stopping the equipment in order to prevent film wastage. From finished product to stable product, the film should be left alone for 2 days before testing (migration time). After this 2 day period, the film friction coefficient should be at its most stable.

Index

plastic masterbatch, master batch, polymer, plastic additive