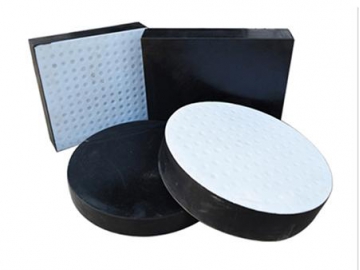

PTFE Rubber Bearing

The PTFE rubber bearing (GJZF4 and GYZF4 series) is made by adhering a 1.5mm-3mm thick PTFE plate to the common rubber bearing.

In addition to the excellent performance of rubber bearing, the PTFE rubber bearing also features low friction coefficient to the stainless steel plate, which makes the horizontal displacement of the superstructure is not limited by the shear deformation of the bearing and can satisfy the needs of large displacement of the bridges. The PTFE rubber bearings are widely used in mining, mechanical and electrical industries.

The bridge rubber bearings feature advanced technologies, excellent performance, simple structure, economical cost, easy maintenance and replacement, shock resistance and low construction height.

- Uneven materials of bearing.

- Silicone grease in not applied during bearing installation which leads to shear failure of the rubber bearings.

- Elevation of padstones is not well controlled. As a result, the bearing force of four bearings of the beam is not balanced which leads to the deformation of the bearing with larger force beyond the specified value.

- When the expansion joints of the bridge are not finished and the traffic is not closed, the passing heavy vehicles' brake will lead to a large shearing force and damage the bearings.

Bracket foundation

In order to install the bracket and provide enough supporting force, a reinforced concrete foundation should be set under the bracket. Because the foundation is in the river channel, where the ground is soft and the bearing capacity is small and uneven. The concrete foundation will cause a large differential settlement. To reduce the settlement, it is necessary to increase the foundation's size and prepress the bracket. This project has huge quantities, long work time, low safety and high expense.

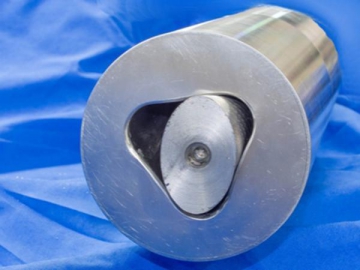

Large-tonnage jack to jack up the bridge span

Ultra-thin unidirectional jack in combination with dial indicator jack up the bridge span. Making full advantage of the space between beam and pier top, a circular flat oil jack (height=70mm, Φ=300mm, max. jacking weight=250t, max. stroke=15mm) with an electric oil pump is utilized to jack up the bridge span. A dial indicator is adopted to observe the jacking speed and guarantee the even force and simultaneous hoisting of beam.