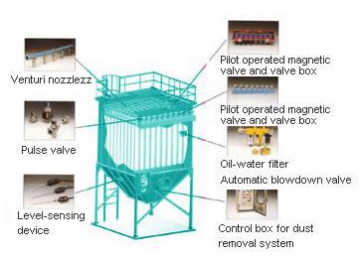

Air Tank Pulse Bag Filter

The air tank pulse bag filter adopts sub-box type cleaning, i.e., each box is isolated during dust removal, thus avoiding secondary dust flying problem. The tank employs the structure of inlet pipe and outlet pipe. The dust hopper can be extended to the bottom of the outlet pipe, making the dust-laden gas directly enter the expanded dust hopper to achieve the purpose of collecting dust in advance. The straight horizontal pipe which is easily blocked is removed. Therefore, our air tank pulse bag filter can process gases with the dust concentration as high as 1000g/m3.

In addition, our product is easy and convenient to maintain. For example, when replacing the filter bag, open the top cover and directly draw out the filter bag to be replaced.

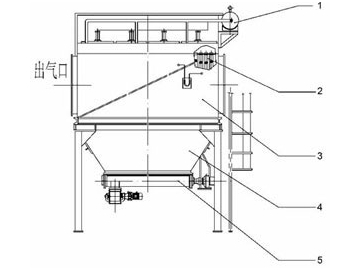

1. Gas tank

2. Filter bag

3. Upper housing

4. Lower housing

5. Screw conveyor

| Model | PPCS32-3 | PPCS32-4 | PPCS32-5 | PPCS32-6 | PPCS64-4 | PPCS64-5 | PPCS64-6 | PPCS64-7 | PPCS64-8 |

| Processing capacity m3/h | 6900 | 8930 | 11160 | 13390 | 17800 | 22300 | 26700 | 31200 | 35700 |

| Total filtering area m2 | 93 | 124 | 155 | 186 | 248 | 310 | 372 | 434 | 496 |

| Net filtering area m2 | 62 | 93 | 124 | 155 | 186 | 248 | 310 | 272 | 434 |

| Number of dust collecting room | 3 | 4 | 5 | 6 | 4 | 5 | 6 | 7 | 8 |

| Number of filter bag | 96 | 128 | 160 | 192 | 256 | 320 | 384 | 448 | 512 |

| Resistance Pa | 1470~1770 | ||||||||

| Dust concentration of gas at inlet g/m3 | <200 or <1000 | ||||||||

| Dust concentration of gas at outlet g/m3 | <0.1 | ||||||||

| Negative pressure withstood by the dust collector housing Pa | 5000 | ||||||||

Related Names

Pulse Jet Dust Collector | Dust Filtration Unit | Industrial Dust Eliminator