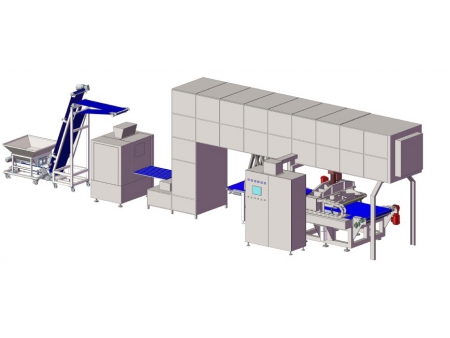

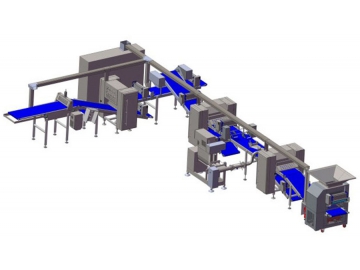

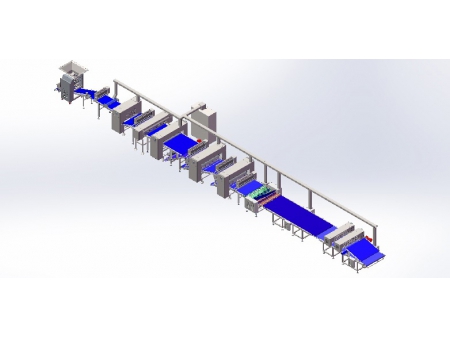

Tortilla Line (With Proffer)

This line makes the tortilla in a traditional way which is pressing the cut dough ball into a even shape. The weight of the divided dough ball can be adjusted to form the ideal bread size. Automatic proofing room can give a good rest / fermentation of the dough ball.

Connected with oven , cooler and packing system, the line can meet the full processing demand.

Hopper

Hopper Divider and Rounder

Divider and Rounder Dough Ball Resting

Dough Ball Resting Resting Room

Resting Room Tortilla Forming Plate

Tortilla Forming Plate 3 Tiers Oven

3 Tiers Oven Conveyor after Cooler

Conveyor after Cooler Flow Pack Machine

Flow Pack Machine Dough Mixer

Dough Mixer

Dough hopper – Dough ball divider & rounder – Rest room- Hot press – oven – cooler – Flow pack machine

- World famous electrical components

- Food grade stainless steel and conveyor belt.

- Controlled by PLC and touch screen

- Equipped with Video monitoring equipment, easy to watch the running situation of main part to reduce the downtime.

- Remote control system to found and optimize the abnormal data

| Industrial output | ≤12000 pcs/hr |

| Dough ball size | 25-60 g/pcs |

| Belt width | 1000 mm |

| Bread size | ≤8 in |

| Power | 102kw |

| Linear speed | ≤12m/min |

| Product shape | Round |

| Hopper height | 900mm |

| Line size | L 12.5m* W 3.0m* H 3.2m |

| Machine weight | 6.5t |

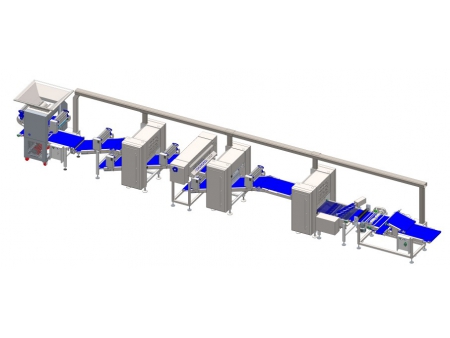

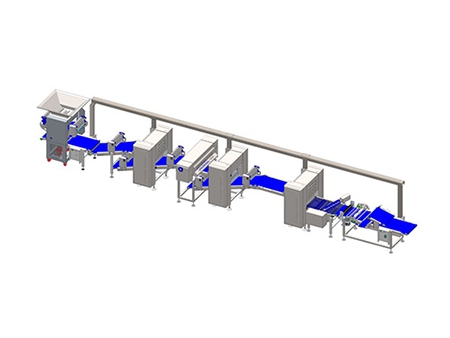

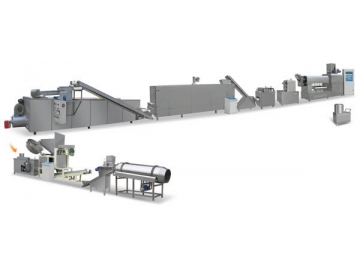

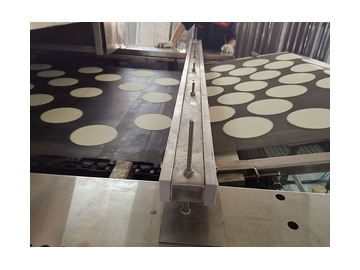

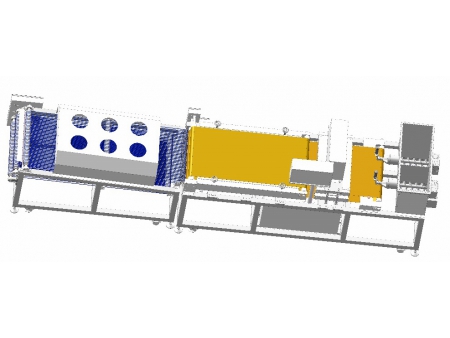

In order to meet clients grand industrial production capacity requirements, ZLINE designed a line to produce tortilla in the way of rotary cutting. And it has already be very popular in the market. This line ensures the tortilla with more uniform thickness and size to higher the quality of the final products.

Also, This forming line is able to be connected to oven, cooler and package machine. Baking time and temperature is adjustable and line can be designed to be placed well at your existing factory/plant.

Cross sheeter

To roll the dough belt horizontally to release its longitudinal tension

Rotary cutting table with dough scrap return unit

Cutter size can be tailored according to clear demand. Speeding is adjustable.

Automatically collecting dough waste dough into containers for reusage.

| Industrial output | Max. ≤23000pcs/min |

| Belt width | 850mm |

| Dough band width | ≤800 mm |

| Thickness range | 1mm-10mm |

| Power | 15kw |

| Linear speed | ≤9m/min |

| Product shape | Round, square, and other customized shape |

| Line type | Straight |

| Hopper volume | No more than 200kg/time |

| Hopper height | 2100mm |

| Line size | L 14m* W 2.5m* H 2.2m |

| Machine weight | 5300kg |

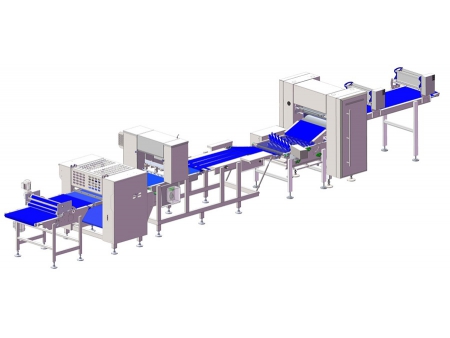

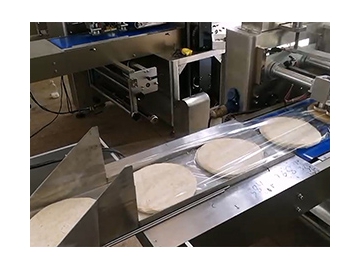

SLBM tortilla line is very popular to small investors because of it small size and stable production capacity. This line is consist of 4 parts: Dough hopper, extruders, oven and S shape cooler. The dough of moisture≥ 65% works well on this system.

Tortillas size and baking temperature can be adjusted automatically on the touch screen.

PLC language is chosen by clients’ needs.

Hopper

Hopper Extruder

Extruder Heating plate

Heating plate- Oven

- S shape cooler

- Touch screen

| Product type | Thin bread with moisture of 50%-80%, thickness: adjustable |

| Product size | 4 ins, 8 ins, 11 ins |

| Production capacity of 2 extruders | 4000pcs/h for 4 ins, 2000pcs/h for 8 ins and 11ins |

| Total power | 32KW |

| Belt with | 700 mm |

| Main material | 304 stainless steel |

| Line size | L5.1m*W1.2*H1.53M |